Electrolytic Tinplate Sheets or Coils for Industrial Package 0.195mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate Sheets or Coils for Industrial Package 0.195mm Description

The origin of tinplate is from Bohemian, from 14th century, the people there began to produce tinplate. Also known as electrolytic tinplate, which stand for tin coating on the surface of cold rolled coil for preventing rust. The unique characteristics of tinplate steel decides its comprehensive range of application in international tinplate packaging industry. With the abundance extend of CC and DR steel material, and tin free steel, which enhance the development of technology of packaging industrialization, the innovation is ubiquitous in tinplate steel.

2.Main Features of the Electrolytic Tinplate Sheets or Coils for Industrial Package 0.195mm

The feature of anti-oxidation, various kinds and beauty in printing enable tinplate enjoys widely usage in food can package, pharmaceutical package, daily application packing, apparatus package and industrial pack.

From the first food can to be produced in the year of 1810 in British, the development trend of tinplate has become thinner thickness and less tin coating to adjust the change of can industry and save cost.

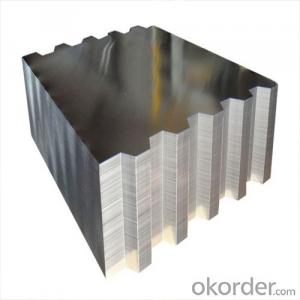

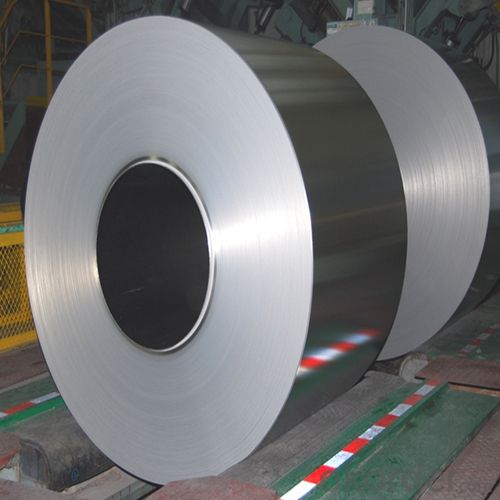

3.Electrolytic Tinplate Sheets or Coils for Industrial Package 0.195mm Images

4.Electrolytic Tinplate Sheets or Coils for Industrial Package 0.195mm Specification

Standard: GB/T2520-2000

Material: MR

Thickness:0.195mm

Width: 615mm

Temper: T4

Annealing: CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface Finish: bright

5.FAQ of Electrolytic Tinplate Sheets or Coils for Industrial Package 0.195mm

- What is the delivery time for your prime quality tinplate?

Usually 45 days after order confirmation for MR steel, and 35 days for SPCC.

- Do you also offer secondary quality stock tinplate?

Yes, we also offer secondary quality stock tinplate especially for industrial use.

- Can you offer some details about your package?

For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

- Which port do you ship from?

We can ship from any China main port, but mostly Shanghai.

- What is the payment term?

The most common we use is L/C at sight or TT. We can also try use other terms.

- Q:Can tinplate be used for packaging luxury goods?

- Yes, tinplate can be used for packaging luxury goods. Tinplate is a versatile material that offers excellent durability, strength, and corrosion resistance. It is also highly customizable, allowing for luxurious finishes such as embossing, metallic effects, and high-quality printing. Additionally, tinplate's premium appearance and classic appeal can enhance the brand image and value of luxury goods.

- Q:What is the shelf life of products packaged in tinplate?

- The shelf life of products packaged in tinplate can vary depending on the specific product and storage conditions. However, tinplate is known for its excellent preservation properties, providing a protective barrier against moisture, light, and oxygen. As a result, many products packaged in tinplate can have a relatively long shelf life, often ranging from several months to several years. It is important to note that proper storage and handling practices, including keeping the products in a cool, dry place away from direct sunlight, can further extend their shelf life.

- Q:How does tinplate contribute to the efficiency of energy systems?

- Tinplate contributes to the efficiency of energy systems by providing a durable and lightweight material that can be used in various components such as cans, containers, and packaging. It helps in preserving and protecting energy resources, reducing energy consumption during transportation, and improving overall energy efficiency in the storage and distribution of goods. Additionally, tinplate is recyclable, which further supports sustainable energy practices and reduces waste in the energy system.

- Q:What is the elongation of tinplate?

- The elongation of tinplate refers to its ability to stretch or deform without breaking or cracking under applied stress. It is a measure of the material's ductility and is typically expressed as a percentage increase in length compared to its original length before deformation.

- Q:Can tinplate be used for signage and advertising purposes?

- Yes, tinplate can be used for signage and advertising purposes. Tinplate is a versatile material that can be easily shaped, printed on, and customized to create attractive and durable signs and advertising displays. It offers a glossy finish and excellent weather resistance, making it suitable for both indoor and outdoor applications. Additionally, tinplate is cost-effective and can be recycled, making it a sustainable choice for signage and advertising needs.

- Q:What is the purpose of tinplate coating?

- The purpose of tinplate coating is to provide a protective layer of tin on the surface of steel, preventing corrosion and enhancing the durability and longevity of the metal.

- Q:What are the main uses of tinplate?

- Tinplate is primarily used in the packaging industry for food and beverage containers, such as cans for canned foods, beverages, and aerosol products. It provides a protective coating to prevent corrosion and maintains the quality and freshness of the products. Additionally, tinplate finds applications in the manufacturing of various household items, decorative products, and electronic components.

- Q:How does tinplate packaging contribute to food safety?

- Tinplate packaging contributes to food safety by providing a protective barrier against external factors that can contaminate or spoil the food. The tin coating acts as a barrier, preventing oxygen, moisture, light, and other contaminants from entering the package, ensuring the food inside remains fresh and safe for consumption. Additionally, tinplate packaging is durable and resistant to damage, reducing the risk of physical contamination. Its ability to maintain the integrity and quality of the food over extended periods further enhances food safety.

- Q:What are the common safety features for tinplate packaging?

- Common safety features for tinplate packaging include: 1. Tamper-evident closures: Tinplate packaging often includes tamper-evident closures such as seals or breakable tabs that indicate if the product has been opened or tampered with. 2. Child-resistant closures: Many tinplate packages are designed with child-resistant closures to prevent young children from accidentally accessing potentially harmful products. 3. Sturdy construction: Tinplate packaging is known for its durability and strength, providing a protective barrier for the contents inside. 4. Chemical resistance: Tinplate packaging is typically resistant to chemicals, preventing any harmful substances from leaching into the product. 5. Recyclability: Tinplate packaging is highly recyclable, making it an environmentally-friendly choice. This feature ensures that the packaging is disposed of properly, reducing waste and environmental impact. 6. Printed warnings and instructions: Tinplate packaging often includes printed warnings and instructions to inform consumers about any potential hazards associated with the product and how to use it safely. These safety features help to ensure that tinplate packaging protects the product, prevents accidents or tampering, and provides necessary information to consumers for safe usage.

- Q:How does tinplate contribute to the safety and integrity of packaged products?

- Tinplate contributes to the safety and integrity of packaged products in several ways. Firstly, tinplate is highly resistant to corrosion, protecting the packaged products from exposure to moisture and other potentially harmful elements. This corrosion resistance ensures that the packaging remains intact, preventing any leakage or contamination of the product. Additionally, tinplate has excellent barrier properties, which means it effectively blocks out oxygen, light, and other external factors that could cause spoilage or degradation of the packaged goods. Furthermore, tinplate provides a strong and sturdy structure for packaging, ensuring that it can withstand transportation and handling without compromising the integrity of the product. Overall, tinplate's properties make it a reliable and protective material for packaging, thereby contributing to the safety and preservation of packaged products.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electrolytic Tinplate Sheets or Coils for Industrial Package 0.195mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords