Electrolytic Tinplate ETP Sheets in good price for Food Cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tinplate, as the name suggests, is coated on both sides with pure tin at various coating weights between 1 and 12 grams per square meter.

It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

TINPLATE SHEET SPECIFICATION

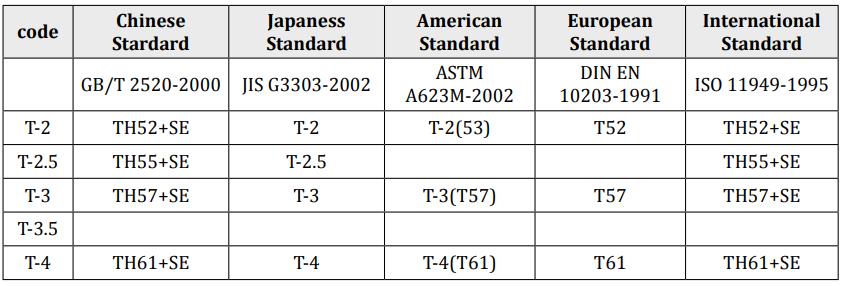

Reference standard: GB/T 2520-2000, JIS G3303-2002 and DIN EN 10203-1991

Raw material: MR and SPCC

Thickness: 0.13 to 0.5mm

Width: 600-1050mm

Length: maximum 1200mm

Temper: T1~T5, DR8~DR10

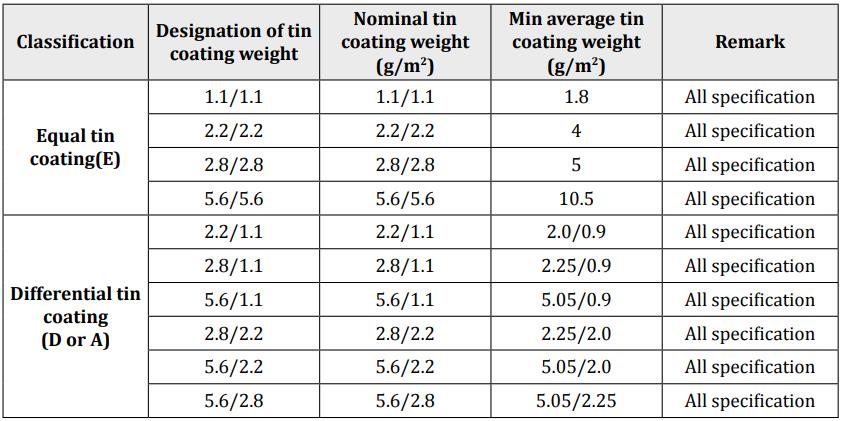

Tin coating: 1.1g~11.2g We can produce according to customer’s requests.

Applications: paint, chemical and other usage can make battery, electric cable and other industries

Package: anti-rust paper, corner protected. Sheets or coils according customer's requests

Stardard

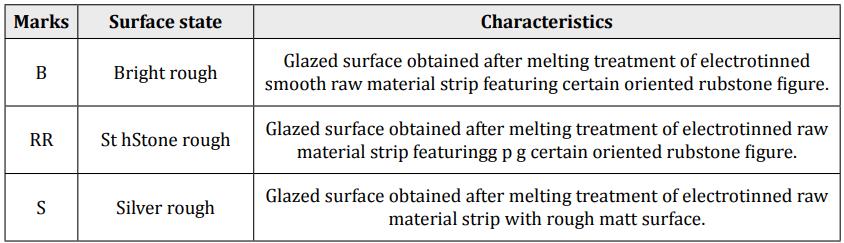

Surface

Coating

APPLICATION

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

◆ Chemicals and painting cans

◆ Dry food cans, such as fancy cans, biscuit cans, milk powder cans, tea cans

◆ Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

◆ Sea food cans

◆ Crown corks, easy open ends (EOE)

◆ Electrical machinery parts

◆ Bakeware and household kitchen parts

- Q:How is tinplate coated for electrical enclosures?

- Tinplate is coated for electrical enclosures through a process called electroplating, where a layer of tin is applied onto a steel sheet. This is achieved by immersing the steel sheet into an electrolyte solution along with a tin anode, and passing an electric current through the solution. The electric current causes the tin ions in the solution to be attracted to the steel sheet, resulting in a thin and uniform tin coating on its surface. This tin coating provides electrical conductivity and corrosion resistance, making the tinplate suitable for use in electrical enclosures.

- Q:How does tinplate contribute to the reduction of plastic waste?

- Tinplate contributes to the reduction of plastic waste by offering a sustainable alternative for packaging. Tinplate containers, such as cans, are widely used for storing food, beverages, and other products, eliminating the need for single-use plastic packaging. These containers are recyclable and have a high recycling rate, diverting a significant amount of waste from landfills. Additionally, tinplate's durability and protective properties help extend the shelf life of products, reducing food waste and the need for excessive packaging.

- Q:Can tinplate packaging be used for chemical products?

- Yes, tinplate packaging can be used for chemical products. It is a common choice for storing and transporting various chemicals due to its durability, resistance to corrosion, and ability to provide a protective barrier against external factors. Tinplate packaging is also compatible with different closure systems, making it suitable for a wide range of chemical products.

- Q:What are the main advantages of using tinplate for electrical enclosures?

- The main advantages of using tinplate for electrical enclosures are its high corrosion resistance, excellent electrical conductivity, and cost-effectiveness. Tinplate provides a protective coating that prevents rust and corrosion, ensuring the longevity of the enclosure. Its conductivity allows for efficient electrical flow and minimizes power loss. Additionally, tinplate is relatively inexpensive compared to other materials, making it a cost-effective choice for manufacturing electrical enclosures.

- Q:What are the main applications of tinplate in the aerosol industry?

- The main applications of tinplate in the aerosol industry include the production of aerosol cans, which are widely used for packaging and dispensing various products such as paints, lubricants, insecticides, and personal care items. Tinplate cans provide excellent barrier properties against moisture, gases, and light, ensuring the integrity and shelf life of the aerosol products. Additionally, tinplate's high strength and durability make it ideal for withstanding the pressure and handling requirements of aerosol packaging.

- Q:What are the main safety regulations for tinplate production and use?

- The main safety regulations for tinplate production and use include ensuring proper ventilation and exhaust systems to prevent exposure to harmful fumes, implementing effective fire prevention and control measures, providing personal protective equipment for workers such as gloves and goggles, conducting regular maintenance and inspection of equipment to prevent accidents, and adhering to strict quality control standards to ensure the safety of the final product. Additionally, proper training and education about safety protocols should be provided to all employees to minimize risks and ensure a safe working environment.

- Q:What are the common safety features for tinplate packaging?

- Some common safety features for tinplate packaging include tamper-evident seals, child-resistant closures, and durable construction to prevent breakage or leakage. Additionally, many tinplate packaging products are also made with food-grade materials to ensure the safety of the contents.

- Q:How does tinplate perform in terms of puncture resistance?

- Tinplate performs exceptionally well in terms of puncture resistance. Its unique combination of strength and durability makes it highly resistant to punctures, making it an ideal material for packaging delicate or sharp objects that require protection.

- Q:What are the main applications of tinplate in the electrical industry?

- Tinplate is widely used in the electrical industry for various applications such as the production of electrical enclosures, transformer tanks, and terminal boxes. Its corrosion-resistant properties make it an ideal material choice to protect electrical components from moisture and other environmental factors. Additionally, tinplate is used for manufacturing electrical connectors, terminals, and busbars due to its excellent electrical conductivity.

- Q:How does tinplate resist corrosion?

- Tinplate resists corrosion due to the protective barrier created by the tin coating on the surface. This tin layer acts as a barrier, preventing direct contact between the base metal and the corrosive elements in the environment, thus preserving the underlying material from degradation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electrolytic Tinplate ETP Sheets in good price for Food Cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords