E20 Emulsion E Glass Fiber Chopped Strand Mat

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 560 kg

- Supply Capability:

- 10000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

E20 Emulsion Chopped Strand Mat

E20 Emulsion Chopped Strand Mat is made of randomly distributed chopped E6 glass strands held together by an emulsion binder. E20 is suitable to reinforce unsaturated polyester, vinyl ester,epoxy and phenolic resins.

E20 is designed mainly for use in the hand lay-up process and also suitable for use in filament winding and continuous laminating processes. Its end-use applications include boats, bath equipment, automotive parts, chemical corrosion resistant pipes, tanks, cooling towers and building components.

Product Features:

◎ Good conformability.

◎ Good wet-through and fast wet-out in resins, rapid air lease, reducing rolling out time and increasing productivity.

◎ Low resin consumption.

◎ High mechanical strength of parts.

◎ Superior acid corrosion resistance.

Product Specifications:

Property | Area Weight(g/m²) | Moisture Content(%) | Size Content(%) | Breakage Strength(N) |

Methods | ISO 3374 | ISO 3344 | ISO 1887 | ISO 3342 |

EMC225 | 225(1±6%) | ≤0.15 | 4.4(1±31%) | ≥80 |

EMC300 | 300(1±6%) | ≤0.15 | 4.0(1±31%) | ≥100 |

EMC375 | 375(1±6%) | ≤0.15 | 3.8(1±31%) | ≥120 |

EMC450 | 450(1±6%) | ≤0.15 | 3.7(1±31%) | ≥140 |

EMC600 | 600(1±6%) | ≤0.15 | 3.5(1±31%) | ≥160 |

EMC900 | 900(1±6%) | ≤0.15 | 3.3(1±31%) | ≥200 |

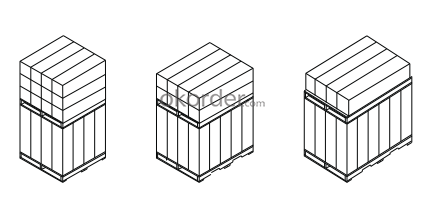

Packaging:

Each Emulsion Chopped Strand Mat is wound onto a paper tube which has an inside diameter of 90mm. The roll outside diameter is approximately 265mm. Each roll is wrapped up in plastic film and then packed in a cardboard box. The rolls are stacked horizontally or vertically onto pallets. All pallets are stretch wrapped and strapped to maintain stability during transport.

Storage:

Unless otherwise specified, the fiberglass products should be stored in a dry,cool and moisture-proof area. The fiberglass products should remain in their original package until prior to use. The room temperature and humidity should be always maintained at -10℃~35℃ and ≤80% respectively. It is best if the product is used within 6 months after production date.

- Q:How does the quality of fiberglass chopped strand affect its performance?

- The performance of fiberglass chopped strand is directly impacted by its quality in various ways. Firstly, the mechanical properties of the final product are significantly determined by the length and consistency of the strands. Longer strands provide superior reinforcement and increased strength, while shorter strands may result in a weaker and less durable material. Moreover, the overall performance of fiberglass is influenced by the diameter and uniformity of the individual strands. Thinner and more consistent strands allow for better resin impregnation during the manufacturing process, leading to enhanced adhesion between the fibers and the matrix. As a result, the material's mechanical properties, such as tensile strength, flexural strength, and impact resistance, are improved. Furthermore, the quality of the surface treatment applied to the chopped strand is crucial. Proper surface treatment ensures good compatibility between the fiber and the resin, facilitating better wetting and dispersion. This ultimately results in improved interfacial bonding and overall mechanical performance of the final composite product. In conclusion, the performance of fiberglass chopped strand is directly influenced by the quality of its fibers in terms of their length, diameter, consistency, and surface treatment. These factors determine the material's mechanical properties, adhesion, and compatibility with the matrix resin, ultimately impacting its overall strength, durability, and performance characteristics.

- Q:What are the health risks associated with exposure to fiberglass chopped strand?

- There are several health risks that can arise from being exposed to fiberglass chopped strand. Firstly, fiberglass consists of small strands of glass that can be easily inhaled if safety measures are not followed. Inhaling these particles can cause irritation in the respiratory system, resulting in symptoms like coughing, wheezing, and difficulty breathing. Extended exposure to fiberglass dust can also lead to chronic respiratory conditions such as asthma or bronchitis. Apart from respiratory issues, fiberglass can also cause irritation to the skin and eyes upon contact. Direct contact with fiberglass particles can cause itching, redness, and rashes on the skin. If these particles come into contact with the eyes, it can cause irritation, redness, and potentially more serious conditions like corneal abrasion. Furthermore, fiberglass chopped strand is often treated with a binder or resin to enhance its properties. These chemicals can release volatile organic compounds (VOCs) into the air, which contribute to indoor air pollution. VOCs can result in various health problems, including irritation in the eyes, nose, and throat, as well as headaches, dizziness, and nausea. Prolonged exposure to high levels of VOCs can even lead to more severe health issues like damage to the liver, kidneys, or central nervous system. To prevent these health risks, it is crucial to take proper safety precautions when working with or around fiberglass chopped strand. This includes wearing protective clothing like gloves, goggles, and a respirator to avoid direct contact and inhalation of fiberglass particles. Adequate ventilation and dust control measures should be implemented to minimize the release of fiberglass dust and VOCs into the air. Regular cleaning and maintenance of the work area also help in reducing the risks associated with fiberglass exposure. Overall, although fiberglass chopped strand has many advantages and applications, it is important to be aware of the potential health risks and to take necessary precautions to safeguard oneself from its harmful effects.

- Q:Does fiberglass chopped strand improve the weathering resistance of composite materials?

- Yes, fiberglass chopped strand does improve the weathering resistance of composite materials. Fiberglass is known for its excellent weathering properties, making it a popular choice for reinforcing composite materials. The chopped strand form of fiberglass consists of small, randomly chopped fibers that are mixed with a resin matrix to create a composite material. The addition of fiberglass chopped strand to composite materials enhances their weathering resistance in several ways. Firstly, fiberglass fibers have a high resistance to UV radiation, which is a major factor in weathering. These fibers act as a barrier, absorbing and dissipating UV rays, preventing them from damaging the underlying resin matrix. This helps to maintain the structural integrity and appearance of the composite material over time. Secondly, fiberglass chopped strand reinforces the composite material, providing additional strength and stiffness. This reinforcement helps the composite material withstand the mechanical stresses caused by weathering, such as wind, temperature fluctuations, and moisture exposure. By improving the overall strength of the composite, fiberglass chopped strand enhances its ability to resist cracking, warping, and other forms of degradation that can occur due to weathering. Furthermore, fiberglass chopped strand also improves the dimensional stability of composite materials. It helps to minimize dimensional changes caused by temperature variations, reducing the risk of warping or distortion. This is particularly important in outdoor applications where composite materials are exposed to a wide range of weather conditions. In conclusion, the addition of fiberglass chopped strand to composite materials significantly improves their weathering resistance. The high UV resistance, reinforcement, and dimensional stability provided by fiberglass chopped strand help the composite materials withstand the detrimental effects of weathering, ensuring their long-term performance and durability.

- Q:How does the orientation of fiberglass chopped strand affect its strength?

- The strength of fiberglass chopped strand is greatly influenced by its orientation. Fiberglass chopped strand consists of randomly oriented glass fibers held together by a sizing agent. When these strands are added to a composite material, their orientation can affect the overall strength of the final product. Typically, the strength of fiberglass chopped strand is determined by the alignment of the fibers with the applied load. Fibers that are aligned parallel to the load direction provide the highest strength as they effectively carry and distribute the stress. This is known as the longitudinal or axial direction. In contrast, fibers that are aligned perpendicular to the load direction, also known as the transverse direction, offer lower strength. This is because these fibers are less effective at resisting the stress and are more prone to breakage. Additionally, the transverse orientation can lead to delamination or separation between the fibers and the resin matrix, resulting in reduced overall strength. The presence of fiber misalignment or voids in the composite material can also impact the strength of fiberglass chopped strand. Non-uniform distribution or improper alignment of the fibers can create weak areas or stress concentration, diminishing the material's overall strength. To maximize the strength of fiberglass chopped strand, it is crucial to ensure proper fiber alignment and distribution within the composite material. This can be achieved through meticulous manufacturing processes, such as employing techniques for uniform and controlled fiber orientation, ensuring adequate resin impregnation, and minimizing the presence of voids or defects. In conclusion, the orientation of fiberglass chopped strand is a crucial factor in determining its strength. By ensuring proper fiber alignment and distribution, the material's ability to withstand applied stress can be enhanced, ultimately contributing to its overall strength.

- Q:Brief introduction of glass fiber cloth

- Statin (similar to unidirectional cloth). It is different from the ordinary fabric, but also can be used in the production of glass fiber reinforced, three-dimensional woven fabrics and other forms of three-dimensional fabric. In certain applications will also further roving short cut, as well as for corrosion resistant occasions, which is generally used in glass mat. The shape of a solid fabric is massive. Alkali free glass fiber tape is commonly used in the manufacture of high strength, rectangular, unidirectional fabrics. Single warp fabric is a kind of coarse and fine warp weft four by breaking satin or long satin fabric, wet mechanical strength shall meet the requirements, greatly improves the shear strength of composites and resistance damage tolerance, and then use the barbed needle acupuncture. It is a continuous glass strand by throwing silk device randomly thrown in continuous mesh belt, such as winding, mould. The dumbbell shaped fabric, flat selvedge and weft density; the fabric made of laminated material to avoid the pollution of the process . The fiber in the continuous glass fiber felt is continuous. The most typical braid is a layer of warp and weft overlap together. Glass cloth is mainly used for producing all kinds of electric insulation laminate.

- Q:How does the diameter of fiberglass chopped strand affect its performance?

- The diameter of fiberglass chopped strands plays a significant role in determining its performance. A smaller diameter generally leads to improved mechanical properties, such as increased tensile strength, flexural strength, and impact resistance. This is because smaller diameter strands have a higher surface area to volume ratio, allowing for a more effective transfer of stress and load across the material. Moreover, smaller diameter strands offer better dispersion and wet-out in resin systems, resulting in improved overall composite properties. This enhanced wet-out ensures better adhesion between the fibers and the resin matrix, leading to increased strength and stiffness of the composite material. Additionally, the diameter of chopped strands affects the processing characteristics of the fiberglass. Smaller diameter strands are more easily dispersed in resin systems, leading to improved flowability and reduced fiber entanglement during molding processes. This allows for better fiber distribution and orientation within the composite, enhancing its overall performance. However, it is worth noting that there is a trade-off between diameter and handling characteristics. Smaller diameter strands can be more difficult to handle during manufacturing processes due to their increased susceptibility to breakage and tangling. Therefore, it is essential to strike a balance between the desired performance characteristics and ease of handling when selecting the diameter of fiberglass chopped strands for a particular application.

- Q:Can fiberglass chopped strand be used in electrical cables?

- No, fiberglass chopped strand is not typically used in electrical cables. Electrical cables require materials that have excellent electrical conductivity and insulation properties, such as copper or aluminum for conductors and various types of insulating materials like PVC, XLPE, or rubber. Fiberglass chopped strand, on the other hand, is primarily used in the manufacturing of composite materials, such as fiberglass reinforced plastics, where its high strength and corrosion resistance characteristics are advantageous.

- Q:Brieaf introduction of carbon fiber?

- Along the fiber axis, it present very high strength; therefore the specific strength of CFRP material intensity and density can be achieved above 2000 MPa; high performance carbon fiber which made from polyacrylonitrile fiber precursors have tensile modulus about 200 to 700GPa. Some studies have pointed out that young's modulus (refers to the physical quantity that is characterized by the tensile or compressive strength of the material within the elastic limit) is 2 times more than that of the glass fiber. High purity and high temperature carbonization were used to prepare high performance PAN based carbon fiber, which gave the fiber chemical activity, viscose based carbon fiber. Carbon fiber's manufacturing progress includs fiber spinning. Comparing with aluminum and other metal materials, it is 7 to 9 times of strength of steel. In the early stage of aerospace grade carbon fiber, 3K is the main category, then the fiber is further produced by crosslinking, with its elongation rate greater than 2%. The equipment is complex, and it is destroyed. As it contains a large number of variables, like oxidation and oxygen, but the first two kinds of carbon fiber is mainly produced. The graphite is generally in the 2500 to 3000℃.

- Q:Can fiberglass chopped strand be used in the production of furniture?

- Yes, fiberglass chopped strand can be used in the production of furniture. It is commonly used to reinforce various materials such as plastics, composites, and resins, providing strength, durability, and stability to furniture designs.

- Q:Can fiberglass chopped strand be used in water treatment applications?

- Yes, fiberglass chopped strand can be used in water treatment applications. Fiberglass is a versatile material that offers excellent resistance to corrosion and chemicals, making it suitable for use in water treatment processes. Chopped strands of fiberglass can be used to reinforce various components such as pipes, tanks, and filters used in water treatment systems. The high strength and durability of fiberglass make it ideal for withstanding the harsh conditions often found in water treatment facilities. Additionally, fiberglass is non-toxic and does not leach harmful substances into the water, ensuring the safety of the treated water.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

E20 Emulsion E Glass Fiber Chopped Strand Mat

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 560 kg

- Supply Capability:

- 10000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords