Fiberglass chopped strand mat high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

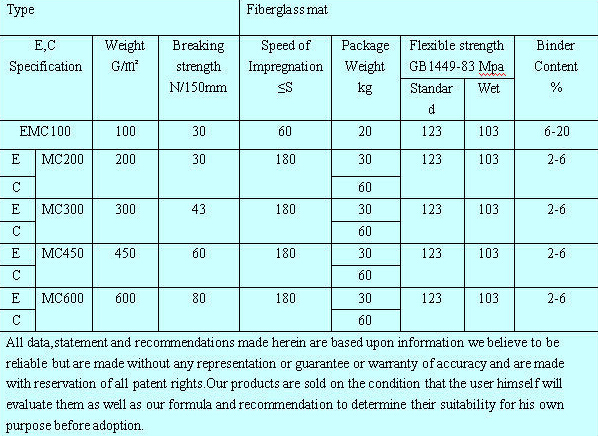

.The Style including the EMC100,EMC200,EMC600.EMCL600.EMCL450,CMC300.CMC450....

2.General width 1040mm/1270mm

3.chopped strand mat is made of randomly dispersed with power or emulsion bonded.

4.Applicable for hand lay -up ,continuous lamination process,compatible with UP VE

5.Suitable for transparent panels,ship ,bodies,automobile parts and interior decorations....

Style :

Packing :

each roll is packed by polyester bag .

2.Every roll in a cardbord box or thhr plastic woven bag

3.30kg with a rollof woven roving

4.Bordbox size : 22*24*114cm

5.The details as per customes requriments

- Q:How is fiberglass chopped strand used in the telecommunications industry?

- Fiberglass chopped strand is widely used in the telecommunications industry for various applications. One of the main uses of fiberglass chopped strand in this industry is for reinforcing the plastic components of communication cables. These cables are responsible for transmitting data, voice, and video signals over long distances. The fiberglass chopped strand is mixed with a thermoplastic resin, such as polyethylene or polypropylene, to create a composite material. This composite is then used to manufacture the outer protective layer or jacket of the communication cables. The fiberglass reinforcement adds strength and durability to the cables, allowing them to withstand harsh environmental conditions, such as extreme temperatures, moisture, and UV radiation. Additionally, fiberglass chopped strand is used in the production of fiber optic cables, which are essential for high-speed data transmission and internet connectivity. In fiber optic cables, the chopped fiberglass strands are impregnated with a UV-resistant resin and wrapped around the glass fibers to provide mechanical protection. This reinforcement helps prevent damage to the delicate glass fibers, ensuring reliable and efficient transmission of data signals. Furthermore, fiberglass chopped strand can be used in the manufacturing of telecommunication equipment, such as antenna radomes. Radomes are protective covers that enclose antennas and protect them from external elements. The chopped fiberglass strands are embedded in a resin matrix to create a lightweight and durable material that offers excellent electromagnetic transparency. This allows the antennas to transmit and receive signals without interference, ensuring optimal performance. In summary, fiberglass chopped strand plays a crucial role in the telecommunications industry by reinforcing communication cables, fiber optic cables, and telecommunication equipment. Its high strength, durability, and resistance to environmental factors make it an ideal material for ensuring reliable and efficient communication networks.

- Q:Can fiberglass chopped strand be used for reinforcing rubber materials?

- Yes, fiberglass chopped strand can be used for reinforcing rubber materials. The fibers provide strength and durability to the rubber, enhancing its overall performance and resistance to wear and tear.

- Q:What are the packaging options for fiberglass chopped strand?

- The packaging options for fiberglass chopped strand typically include bulk bags, cardboard boxes, and plastic bags.

- Q:What are the weathering resistance properties of fiberglass chopped strand?

- The weathering resistance properties of fiberglass chopped strand are generally quite good. Fiberglass is known for its durability and ability to withstand various environmental conditions. It is resistant to UV radiation, moisture, and temperature fluctuations. This makes it highly suitable for outdoor applications where exposure to sunlight and weather elements is common. Fiberglass chopped strand can maintain its structural integrity and aesthetic appeal even when exposed to harsh weather conditions such as intense sunlight, rain, wind, and extreme temperatures. It does not degrade or deteriorate easily, making it a reliable material for long-term use. The resin used to bind the fiberglass strands together also plays a crucial role in enhancing its weathering resistance properties. Advanced resin formulations can provide additional protection against UV radiation and other environmental factors, further improving its resistance to weathering. However, it is important to note that the specific weathering resistance properties of fiberglass chopped strand can vary depending on various factors such as the quality of the material, manufacturing process, and specific environmental conditions it is exposed to. Therefore, it is recommended to consult the manufacturer or supplier for detailed information on the weathering resistance properties of a specific fiberglass chopped strand product.

- Q:What is the melting point of fiberglass chopped strand?

- The melting point of fiberglass chopped strand typically ranges from 1,100 to 1,400 degrees Celsius (2,012 to 2,552 degrees Fahrenheit).

- Q:Does fiberglass chopped strand have any magnetic properties?

- Negative, fiberglass chopped strand does not possess magnetic properties. Comprising slender strands of glass fiber, fiberglass constitutes a non-magnetic substance. It lacks any magnetic attraction or repulsion and does not disrupt magnetic fields.

- Q:Can fiberglass chopped strand be used in the production of insulation foams?

- No, fiberglass chopped strand is not typically used in the production of insulation foams. Insulation foams are typically made from materials like polyurethane foam or polystyrene foam.

- Q:Is chopping glass fiber harmful to human?

- Classification of glass fiber (5) poor water-absorbing quality. The glass fiber monofilament diameter rangingfrom a few microns to twenty micron, with the development speed aheading. Its characteristics are as follows. (2) the elasticity coefficient is high, and the heat resistance is good: (1) High tensile strength It is widely used in various fields of national economy, but it is not suitable for being structural material thread, with the character of noninflammability, no radiation and special odors. (7) preety machinability. The English name is, therefore, with the resin to give shape after finally it can become excellent structural material, usually used as a composite material in the reinforcement material. (6) scale stability. (8)The transmission and light transmission make the use of glass fibers more broadly than other species of fibers, and it is insulating materials and insulation materials. Each bundle of fibers are made of hundreds or even thousands of root root filaments, woven cloth and other products, different the morphology of the staple fiber and glass fiber, so the absorption of impact energy is good: Glass fiber is equivalent to a hair and an be buddle into a strand. Glass fiber increases the intensity with diameter smaller. It is easily lunge the skin and belongs to a crisp fiber. (10) the price is cheap and fiber is very thin. Properties of glass fiber, high alkali: Finally, it becomes various types of products, so take good care of it.

- Q:Is fiberglass chopped strand suitable for automotive interior panels?

- Automotive interior panels can indeed be made from fiberglass chopped strand. This material is comprised of short strands of glass fibers that are dispersed randomly and bonded together. It possesses a lightweight and strong nature, along with excellent dimensional stability, making it an ideal option for such panels. Choosing fiberglass chopped strand ensures an outstanding strength-to-weight ratio, which is vital for panels to endure daily wear and tear while keeping the vehicle's weight in check. Moreover, this material exhibits good resistance to chemicals, heat, and impact, further enhancing its appropriateness for automotive applications. Its versatility permits easy molding and shaping into intricate panel designs, guaranteeing a perfect fit for automobile interiors. All in all, fiberglass chopped strand is a dependable and durable material that fulfills the specific requirements of automotive interior panels.

- Q:Can fiberglass chopped strand be used in sporting goods applications?

- Yes, fiberglass chopped strand can be used in sporting goods applications. It is commonly used to reinforce various components in sporting goods such as hockey sticks, tennis rackets, golf clubs, and even surfboards. The fiberglass adds strength and durability to these products, making them more suitable for rigorous use.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass chopped strand mat high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords