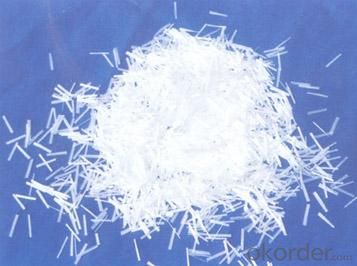

Wet Fiber Glass Chopped Strands

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Wet Chopped Strands are compatible with unsaturated polyester, epoxy and phenolic resins and gypsum.

Wet Chopped Strands have moderate moisture content and deliver outstanding flowability, including dispersion in water and in gypsum.

2.Product Features:

Excellent dispersion in water

Good bonding with multiple resins

Outstanding tensile and tear properties in the final product

3.Product Specifications:

Property | Fibre diameter | Moisture Content | Size Content | Chop |

| (%) | (%) | (%) | (%) |

Mathods | IS01888 | ISO3344 | ISO1887 |

|

3mm | ±10 | ≤3.0 | 0.1±0.05 | 98 |

6mm | ||||

12mm | ||||

18mm |

Special specification can be produce according to customer requirements.

4.FAQ

a.Packaging:

Each bag can be taken (15-25kgs)。 Could also take a big container bag.

b.Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q:How does fiberglass chopped strand reinforce composite materials?

- Composite materials often use fiberglass chopped strand as a reinforcing material due to its exceptional strength and durability. When incorporated into a composite matrix, such as epoxy or polyester resin, the chopped strand acts as a reinforcement by distributing and transferring stress throughout the composite structure. The fibers within fiberglass chopped strand are randomly oriented, providing reinforcement to the composite material in multiple directions. This results in the composite gaining strength in all orientations, making it highly resistant to tensile, compressive, and shear forces. The robust tensile strength of fiberglass chopped strand enables it to withstand heavy loads and prevent the composite material from breaking or fracturing when subjected to stress. Furthermore, the fibers also enhance the impact resistance of the composite, making it more resilient to sudden impacts or vibrations. Moreover, the durability of fiberglass chopped strand makes it an excellent choice for reinforcing composite materials. It exhibits exceptional resistance to corrosion, chemicals, and UV radiation, ensuring the stability and integrity of the composite material over time. This durability also contributes to the longevity and dependability of the composite structure. In conclusion, fiberglass chopped strand reinforces composite materials by providing multidirectional reinforcement, enhancing tensile strength, improving impact resistance, and ensuring long-term durability. Its inclusion in the composite matrix significantly enhances the overall mechanical properties and performance of the composite material, making it applicable for a wide range of industries and applications.

- Q:How is fiberglass chopped strand used in the automotive industry?

- Fiberglass chopped strand is extensively used in the automotive industry for various purposes due to its unique characteristics and benefits. One of the primary uses of fiberglass chopped strand in the automotive industry is for reinforcing plastic parts and components. By adding fiberglass chopped strand to plastic materials, the strength, stiffness, and impact resistance of the final product can be significantly improved. This reinforcement is crucial for ensuring the durability and safety of various automotive parts, such as bumpers, dashboards, door panels, and interior trims. Additionally, fiberglass chopped strand is also used in the automotive industry for sound insulation and vibration damping purposes. The fibrous nature of fiberglass helps to absorb and dissipate noise and vibrations, making the vehicle quieter and more comfortable for the occupants. This is particularly important in reducing road and engine noise, providing a more enjoyable driving experience. Furthermore, fiberglass chopped strand is utilized in the production of composite materials, which are increasingly being used in the automotive industry. These composites, consisting of fiberglass chopped strand and a resin matrix, offer excellent strength-to-weight ratio, corrosion resistance, and design flexibility. They can be molded into complex shapes, allowing for the production of lightweight yet strong automotive parts, such as body panels, hoods, and roofs. In summary, fiberglass chopped strand plays a vital role in the automotive industry by enhancing the strength, stiffness, impact resistance, and acoustic properties of various plastic components. Its usage improves the overall performance, safety, and comfort of vehicles, while also enabling the production of lightweight and durable parts through composite materials.

- Q:Can fiberglass chopped strand be used in electrical insulating applications?

- Indeed, fiberglass chopped strand finds utility in electrical insulating applications. Fiberglass proves itself as a superior insulator boasting remarkable dielectric strength, rendering it fitting for employment in electrical insulation. Chopped strand fiberglass serves as reinforcement and insulation for diverse electrical components like transformers, circuit boards, and electrical cables. It imparts mechanical strength, thermal insulation, and electrical insulation attributes, thereby endowing it with versatility for electrical applications. Moreover, fiberglass chopped strand exhibits resistance to moisture, chemicals, and fire, augmenting its aptness for electrical insulating endeavors.

- Q:How is fiberglass chopped strand used in the medical industry?

- Fiberglass chopped strand is commonly used in the medical industry for various applications. It is primarily used as a reinforcing material in the production of orthopedic casts and splints. The chopped strands are embedded in a resin matrix, forming a strong and lightweight structure that provides support and immobilization to injured limbs. Additionally, fiberglass chopped strand can also be used in the manufacture of prosthetic devices, such as braces and supports, due to its excellent strength and flexibility properties.

- Q:What are the typical fillers used with fiberglass chopped strand?

- The typical fillers used with fiberglass chopped strand include calcium carbonate, talc, and glass microspheres.

- Q:Is fiberglass chopped strand suitable for architectural applications?

- Architectural applications can benefit greatly from the use of fiberglass chopped strand. This versatile material offers numerous advantages and is well-suited for architectural purposes. It is lightweight, strong, durable, and resistant to corrosion, making it an excellent choice for a variety of architectural components. When it comes to architectural applications, fiberglass chopped strand has a wide range of uses. It can be used to reinforce architectural panels, walls, and ceilings, providing additional strength and stability. Furthermore, fiberglass can be molded into different shapes and forms, allowing architects to explore creative design possibilities. Architects can also utilize fiberglass chopped strand to create distinctive architectural features like columns, domes, and arches. Its malleability enables it to be easily shaped and formed into intricate designs, offering architects the flexibility to create visually appealing structures. Another advantage of fiberglass chopped strand is its resistance to fire and chemicals. This makes it suitable for architectural applications where fire and chemical resistance are crucial factors to consider, especially in industrial or commercial buildings. Moreover, fiberglass chopped strand is a cost-effective alternative to materials like steel or concrete. It requires less maintenance and has a longer lifespan, making it a cost-efficient choice for architectural projects. In conclusion, fiberglass chopped strand is an ideal material for architectural applications due to its lightweight nature, strength, durability, corrosion resistance, fire resistance, chemical resistance, and cost-effectiveness. Its versatility and ability to be molded into various shapes and forms make it an excellent choice for architectural components and features.

- Q:Is fiberglass chopped strand suitable for marine structural applications?

- Yes, fiberglass chopped strand is suitable for marine structural applications. It is a durable and corrosion-resistant material that can withstand the harsh marine environment, making it ideal for use in boat hulls, decks, and other structural components. Its high strength-to-weight ratio and excellent impact resistance also make it a popular choice in the marine industry.

- Q:Can fiberglass chopped strand be used in the production of wind turbine hubs?

- Yes, fiberglass chopped strand can be used in the production of wind turbine hubs. Fiberglass chopped strand is a type of glass fiber reinforcement that is commonly used in various industries, including the manufacturing of wind turbine components. It provides strength, stiffness, and durability to the final product, making it an ideal material for wind turbine hubs. The fiberglass chopped strand can be combined with resin and molded into the desired shape, providing a lightweight and robust hub that can withstand the forces and stresses experienced during wind turbine operation. Additionally, fiberglass is corrosion-resistant and has excellent fatigue resistance, making it well-suited for long-term use in wind turbine hubs.

- Q:Can fiberglass chopped strand be used in electrical cables?

- Typically, electrical cables do not utilize fiberglass chopped strand. They necessitate materials with exceptional electrical conductivity and insulation properties, such as copper or aluminum for conductors, and a variety of insulating materials like PVC, XLPE, or rubber. Conversely, fiberglass chopped strand is mainly employed in manufacturing composite materials like fiberglass reinforced plastics, where its advantageous attributes of strength and corrosion resistance come into play.

- Q:Does fiberglass chopped strand have any biodegradability?

- Fiberglass chopped strand lacks any biodegradability, indeed. It is essentially a reinforced plastic derived from delicate glass fibers. These fibers possess a remarkable resistance to decomposition through natural means and remain intact indefinitely. Consequently, fiberglass chopped strand is not subject to biodegradation and can endure within the environment for an extended duration.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wet Fiber Glass Chopped Strands

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords