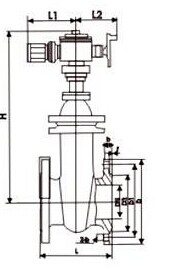

DN150 Ductile Iron Gate Valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Soft seal gate valve

Size:DN40mm-600mm

Design standard: DIN 3352/BS 5163/AWWA C509/JIS B2043

Test standard: DIN3230/BS 6755/AWWA C509/JIS B2003

End flange standard: DIN 2533 PN16/BS 4504 PN16/ANSI 150LB/JIS B2212 10K

Face to face standard: DIN 3202 F4/DIN 3202 F5/BS 5163/ANSI 16.10/JIS B2002

Body: Ductile iron/GGG50/A536

Wedge: Ductile iron+EPDM/Ductile iron+NBR

Stem: Brass/SS416/2Cr13

Bonnet: Ductile iron/GGG50

Handwheel: Ductile iron/GGG50

The products are widely used in water source projects, urban water supply and drainage, sewage treatment, eletric power, petroleum, petrochemical, heat supply, shipbuilding, medicine and metallurgy industries. Equipment are used for regulating or cutting off media in pipelines. Suitable media include water sewage, sea water, air, foodstuff and oil. Suitable for gear operators, electric and pneumatic control actuators.

- Q:What is plug welding gate valve?

- Socket welding valve valve cover design in three forms. The first is forging steel bolt type valve cover, according to this design form design of the valve, the valve body and the valve cover bolt nut connection, spiral wound gasket 316 clamp flexible graphite manufacturing: seal. Customers have special requirements can be used when the metal ring connection. Second design form is the welded bonnet, according to this design form of the valve, the valve body and the valve cover with a threaded connection, welded seal. Customers have special requirements can be used when the third is connected through welding. Self sealing valve cover, according to this design form design of the valve, the valve body and valve cover with a threaded connection, pressure from the dense ring seal.The editing characteristics of 1 valve design and manufacture in accordance with API602 and ASME B16.34. tested according to API 598, marked by MSS-SP-25.2. full diameter or diameter shrinkage 3 rod bracket type 4 self centering sleeve type 5 pressure plate bolt connection, spiral wound gasket seal type valve cover nut connection, welded seal type valve cover and screw connect the internal pressure self tightening type valve cover 6 integral sealing seat 7 socket end with ASME B16.118. threaded end (NPT) with ANSI/ASME B1.20.19. valve can be transformed into the throttle type, needle type, ball type and type check

- Q:What is the meaning of socket welding gate valve A105, D&S:STLT, STEM:13Cr, CL800, SW, AP1602, BB-BG-OS&Y?

- Body material: A105Sealing surface material: STLStem material: 13CrPressure rating: CL800Connection: SWImplementation criteria: AP1602BB-BG-OS&Y: plain rod support, bolt connection, flange valve cap.

- Q:What are the advantages and disadvantages of flat gate valves?

- The disadvantage of flat gate valve is that when the medium pressure is low, the sealing force of the metal sealing surface is insufficient, so as to achieve satisfactory sealing. On the contrary, when the medium pressure is high, if the sealing surface is not lubricated by the system media or foreign media, often opening and closing may cause the sealing surface to wear too much. Another disadvantage is that the circular motion of the circular gate in the circular flow, only when it is at the valve closed position of 50%, this valve is more sensitive to flow control. Moreover, the gate will produce severe vibration when it breaks the high-speed and dense medium flow. The valve seat can also be throttled if the seat is made of a V - shaped opening and is tightly oriented to the gate.

- Q:What are the structural differences between parallel and wedge valves?

- The advantages of dual gate plate is sealed and angle precision low temperature is not easy to make the wedge gate, the abrasion of the sealing surface and shim.The disadvantage is that the structure is complex, easy to stick in the dry medium, mainly the upper and lower baffles. After years of corrosion, the gate is easy to fall off. Although the single gate is sealed and angle accuracy requirements are relatively high, difficult processing and temperature change may make the gate wedge and other shortcomings, but has the advantages of simple structure, reliable use, especially to the flexible gate, can produce the micro elastic deformation to compensate for the deviation between the sealing surface angle processing, which is widely used at present.For more information about valves, please keep an eye on the valve knowledge section.

- Q:What's the meaning of the gate valve model z41x 16Q?

- Gate valve (Z) flange connection (4) wedge type single gate (1) rubber soft seal (X) -16 pressure) (Q)

- Q:What is wire feed gate valve? What do you say in French?

- Point to the wire gate valve. Refers to the valve body with internal thread or external thread, and pipe thread connection. Also called thread valves, threaded valves, valves within the toothFlange gate valve is connected to the flange gate valve, this connection is the most common wayThe main difference is the connection

- Q:What gate valve is the J41H-150LBDN100 gate valve?

- This is a stop valve, not a gate valve.Gate valve means Z41H-150LB-DN100Wenzhou shintex Valve Manufacturing Co. Ltd.0577Eight thousand six hundred and ninety-oneSeven thousand five hundred and sixteenCall

- Q:What are the features and uses of the gate valve?

- What is gate valve? What is the purpose of forged steel gate valves? What are the features of forged steel gate valves?Is the gate valve opening and closing parts, RAM direction of motion perpendicular to the direction of the fluid, valve can only be fully open and fully closed, can not be adjusted and the throttle. The gate valve movement direction perpendicular to the direction of the fluid, valve can only be fully open and fully closed, can not be adjusted and the throttle. The gate has two sealing surfaces, and the two sealing surfaces of the most commonly used gate valves form wedge and wedge angles vary with valve parameters. Gate valve drive classification: manual gate valve, pneumatic gate valve, electric gate valve.DefinitionGate valve means the closing of the valve (gate) along the central line of the vertical direction of the valve. The gate valve is mainly used for cutting in the pipeline.The valve is a valve with a very wide, cutting device general caliber DN = 50mm use it, sometimes a small diameter cutting device also use valve, gate valve has the following advantages:Fluid resistance is small.Minor force needed for opening and closing.Medium flow is unrestricted.When opening fully, the sealing surface is eroded by the working medium smaller than the cut-off valve.The shape is relatively simple and the casting process is betterValve also has shortcomings:The overall size and opening height are larger. Larger space required for installation.In the process of opening and closing, there is relative friction between the sealing surfaces, which may cause galling.Gate valve generally has two sealing surface, processing, grinding and maintenance to increase some difficulties.

- Q:The legend of gate valve and stop valve

- When the valve is installed, the medium can enter from the bottom of the valve core and enter the two way from the top. Medium from the spool into the advantages of the valve closed when the packing is not under pressure, can extend the service life of the packing, and can be pressure in front of the valve in the case of replacement of packing work. Medium from the spool into the bottom of the shortcomings of the valve driving torque is larger, about 1.05~1.08 times above the entrance, the stem by the axial force of large, easy to bend the stem. To this end, the media from below to enter the way, generally only applicable to small caliber manual stop valve, to the valve closed, the media acting on the spool of force is not greater than 350kg limit. Electric cut-off valve is generally used to enter the media from the top way. The disadvantage of the medium entering from the top is just the opposite of the way it is entered below.Compared with the gate valve, the utility model has the advantages of simple structure, good sealing performance, and convenient manufacture and maintenance. The disadvantage is that the liquid resistance is large, and the opening and closing force is large. Gate and globe valves are fully open closed type valve, cut off or connected as the medium use, not as a control valve.The range of application of stop valves and gate valves is determined by their characteristics. In the smaller passages, the cut-off valve is used when required for better shutoff; in the steam pipe and the large diameter water supply pipe, the gate valve is generally used because of less fluid resistance.

- Q:What is the difference between gate valve and gate valve? Is it the same valve?

- The same, very few people call gate valve, all call gate valve.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

DN150 Ductile Iron Gate Valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords