Dia20mm-Dia150mm Forged Steel Grinding Ball for Ball Mill Use with High Hardness and Good Wear Resistant

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Dia20mm-Dia150mm Forged Steel Grinding Ball for Ball Mill Use with High Hardness and Good Wear Resistant

1.Weight and Hardness of Dia20mm-Dia150mm Forged Steel Grinding Ball for Ball Mill Use with High Hardness and Good Wear Resistant

Nominal diameter | Diameteical Tolerance | Weight of single ball in average | Surface hardness | Impact toughness |

(mm) | (mm) | (g) | (HRC) | (j/cm2 ) |

Φ20 | +2 -1 | 32 | 55-65 | ≥12 |

Φ25 | 64 | |||

Φ30 | 110 | |||

Φ40 | 263 | |||

Φ50 | 513 | |||

Φ60 | +3 -2 | 888 | ||

Φ70 | 1410 | |||

Φ80 | 2104 | |||

Φ90 | 2996 | |||

Φ100 | 4110 | |||

Φ110 | +4 -2 | 5457 | 50-60 | |

Φ120 | 7102 | |||

Φ130 | 9030 | |||

Φ140 | +4 -3 | 11278 | ||

Φ150 | 13871 |

2.Physical Property of Dia20mm-Dia150mm Forged Steel Grinding Ball for Ball Mill Use with High Hardness and Good Wear Resistant

Material | Impact Test(Ak.J/cm²) | Endurance Test Times(5m/T) | Surface Hardness (Φ25mm- Φ60mm) | Core Hardness (Φ25mm- Φ60mm) | Surface Hardness (Φ70mm- Φ100mm) | Core Hardness (Φ70mm- Φ100mm) | Breakage |

50Mn | ≥12 | ≥10000 | ≥56 | ≥35 | ≥56 | ≥28 | <0.5% |

60Mn | ≥13 | ≥10000 | ≥58 | ≥38 | ≥58 | ≥29 | <0.5% |

65Mn | ≥15 | ≥12000 | ≥60 | ≥42 | ≥60 | ≥30 | <0.5% |

B2 | ≥17 | ≥12000 | ≥60 | ≥52 | ≥60 | ≥50 | <0.5% |

75SiMn | ≥16 | ≥12000 | ≥60 | ≥50 | ≥60 | ≥48 | <0.5% |

Wear-resistant Alloy | ≥17 | ≥12000 | ≥60 | ≥54 | ≥60 | ≥48 | <0.5% |

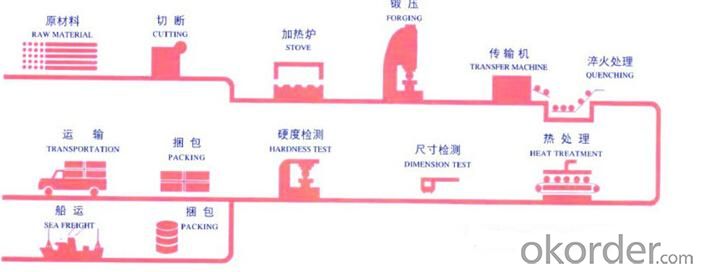

3.Production Process of Dia20mm-Dia150mm Forged Steel Grinding Ball for Ball Mill Use with High Hardness and Good Wear Resistant

3.Packing Ways of Dia20mm-Dia150mm Forged Steel Grinding Ball for Ball Mill Use with High Hardness and Good Wear Resistant

- Q:How to improve the surface roughness of casting parts?

- One is to improve the accuracy of the model; the two is to improve the molding sand mesh. How much is the other relationship?.

- Q:Why do casting parts have air holes?

- Cangshan Qiao hidden his answer is quite comprehensive, you can try using inert gas to reduce air cover

- Q:What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- For the nodular cast iron, the hardness, strength and wear resistance are improved, such as used in the manufacture of automobile, tractor, diesel engine crankshaft, connecting rod and other important parts. A normalizing and hypereutectoid ball annealing before, can eliminate the mesh two cementite spheroidizing annealing, to ensure that all spheres of cementite. Annealing is a metal heat treatment process, which means the metal is slowly heated to a certain temperature, sufficient for a long time, and then cooled at an appropriate speed. The purpose is to reduce hardness, improve machinability, eliminate residual stress, stabilize size, reduce deformation and crack tendency, refine grain, adjust microstructure and eliminate tissue defects. Its purpose: (1) reduce hardness and improve machinability; (2) eliminate residual stress, stabilize size, reduce deformation and crack tendency; (3) refine grain, adjust microstructure and eliminate tissue defects. In production, annealing process is widely used.

- Q:Why does the precision casting factory not usually make iron castings?

- Because it is too cheap, the design of materials is cast iron, generally do not have very high requirements.

- Q:What are the factors affecting the machining process of the casting material and structure?

- Medium carbon steel begins, and the casting can not be punched and tapped directlyStainless steel, ordinary grade (Fe based alloy element content, less) can not do heat treatment. But processing small holes or tapping to heat treatment (solution. In practice, the annealing treatment can also be). There are a lot of stainless steel matrix is not to say, for example, nickel, cobalt and tungsten. And so on.

- Q:How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q:What is the difference between casting and stamping parts?

- Cold stamping is generally no longer done by cutting, or only a small amount of cutting is required. The precision and surface state of hot stamping parts are lower than those of cold stamping parts, but they are better than those of castings and forgings, and the amount of cutting is less.Stamping is mainly based on process classification, can be divided into separation process and forming process two major categories.

- Q:Where is the precision casting factory?

- Shandong, DongyingThe birthplace of precision casting

- Q:What are the general technical requirements for casting parts?

- No matter what kind of material casting, there are the following major requirements:Material requirements. Mainly hardness, tensile strength, elongation, impact toughness.Two, dimensional accuracy and shape accuracy. Different castings have different requirements. Different sizes and geometric tolerances and different tolerances are adopted.Three, according to the use requirements, the casting of other defects, acceptance requirements. Such as holes, sand holes, shrinkage, slag, sand, crack.........Four. Requirements for defect repair.

- Q:What's the cause of the choking of the casting?,

- Causes of choking fire:1., casting material in the pouring of gas;

1. Manufacturer Overview |

|

|---|---|

| Location | Zhangqiu, China |

| Year Established | 1995 |

| Annual Output Value | 150,000M.T. |

| Main Markets | 40%,South America; 30%,South Africa; 15%,Southeast Asia; 5%, Europe Area; 5%, North America; 5%, Other Areas |

| Company Certifications | ISO9001:2008;SGS Test Report |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao;Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | 25 |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 68,000m2 |

| No. of Production Lines | 15 |

| Contract Manufacturing | |

| Product Price Range | $700/M.T.-$1200/M.T. |

Send your message to us

Dia20mm-Dia150mm Forged Steel Grinding Ball for Ball Mill Use with High Hardness and Good Wear Resistant

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords