Cuplock Scaffolding System As10.8 Q345 for Supply CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Cuplock Scaffolding System As10.8 Q345 for Supply

Model NO.:

Type:

Application:

Forming:

Standard:

Member:

Trademark:

Connection Form:

Carbon Structural Steel:

Residential Wall Structure:

Type of Steel For Building Structure:

Bs1139, En74 Standard:

Export Markets:

Descriptions of Cuplock Scaffolding System As10.8 Q345 for Supply

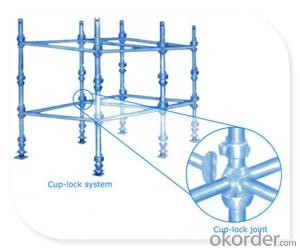

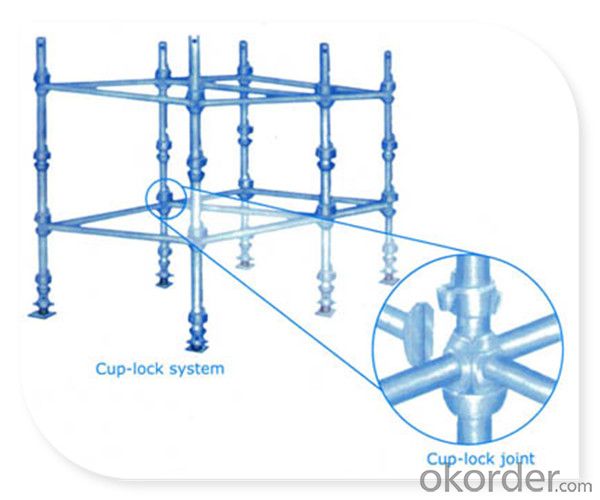

Cuplock is a kind of multi-purpose and versatile modular system scaffolding, suitable for access and formwork support in all types of construction of building & civil engineering projects, offshore projects, etc. This complete galvanized Cuplock system is probably the fastest and most widely preferred scaffolding system. It has flexible erection as straight, curved or circular configuration for both access and support purposes.

Futures of Cuplock Scaffolding System As10.8 Q345 for Supply

Multi-functional-with the universal joint and fully interchangeable components, the cuplock system can be used in most construction projects for both formwork and access. It is very versatile and diverse. Use in the shipping industries, oil and gas and aviation industries.

Versatile-Verticals are assembled with horizontals and diagonals using secure fixed cup connections. Its versatility has a distinct advantage to conventional scaffolding methods. A positive & ridged connection of four units is achieved in one single action. The cupock system is very cost effective and can be erected safely and quickly.

Time saving-cuplock scaffold is the solution for temporary structures Performance stages. Small teams can erect it safely and quickly.

Economical-Easily assembled system scaffold saves time and labor costs.

Durable-All components are hot dip galvanized and manufactures to international standard.

Easily Stored-Individual pipe elements can be packed in bundles for easy storage and transportation. For returns, material can be packed in steel racks.

The Main Components of Cuplock Scaffolding System As10.8 Q345 for Supply

Verticals

Description

Material

kg/pc

Article No.

9'10" Vertical 3.00m

Q345 φ48.3×3.2

16.90

SC1001 3000

8'2" Vertical 2.50m

Q345 φ48.3×3.2

14.20

SC1001 2500

6'6" Vertical 2.00m

Q345 φ48.3×3.2

11.60

SC1001 2000

4'11" Vertical 1.50m

Q345 φ48.3×3.2

8.90

SC1001 1500

3'3" Vertical 1.00m

Q345 φ48.3×3.2

6.20

SC1001 1000

1' Vertical 0.50m

Q345 φ48.3×3.2

3.50

SC1001 0500

Horizontals

Description

Material

kg/pc

Article No.

10'0" Horizontal 3.05m

Q345 φ48.3×3.2

11.80

SC1002 3048

9'0" Horizontal 2.74m

Q345 φ48.3×3.2

10.70

SC1002 2743

8'2" Horizontal 2.50m

Q345 φ48.3×3.2

9.80

SC1002 2500

7'0" Horizontal 2.13m

Q345 φ48.3×3.2

8.40

SC1002 2133

6'6" Horizontal 2.00m

Q345 φ48.3×3.2

7.90

SC1002 2000

6'0" Horizontal 1.83m

Q345 φ48.3×3.2

7.20

SC1002 1828

5'11" Horizontal 1.80m

Q345 φ48.3×3.2

7.10

SC1002 1800

5'0" Horizontal 1.52m

Q345 φ48.3×3.2

6.10

SC1002 1524

4'11" Horizontal 1.50m

Q345 φ48.3×3.2

6.00

SC1002 1500

4'1" Horizontal 1.25m

Q345 φ48.3×3.2

5.00

SC1002 1250

4'0" Horizontal 1.22m

Q345 φ48.3×3.2

4.90

SC1002 1219

3'6" Horizontal 1.07m

Q345 φ48.3×3.2

4.30

SC1002 1067

3'3" Horizontal 1.00m

Q345 φ48.3×3.2

4.10

SC1002 1000

3'0" Horizontal 0.91m

Q345 φ48.3×3.2

3.80

SC1002 0914

2'11" Horizontal 0.90m

Q345 φ48.3×3.2

3.70

SC1002 0900

8'0" Horizontal 2.44m

Q345 φ48.3×3.2

9.50

SC1002 2438

1'10" Horizontal 0.57m

Q345 φ48.3×3.2

2.40

SC1002 0600

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q:Is it easier to build a disc scaffolding system than a bowl buckle scaffold?

- Disc scaffolding systemIs a new type of scaffolding, the product was introduced in Europe in the last century in 80s, is the upgrading of products after the bowl buckle scaffold. Also called chrysanthemum disc scaffolding, scaffold system, disc scaffolding system, buckle disc scaffolding, layher frame (layer frame, Lei Ya frame, because the basic principle of the scaffold is by the German LAYHER (Lei Ya)'s invention, the industry has been called the "thunder sub frame"

- Q:What are the safety requirements for the dismantling of construction scaffolding

- (1) prior to the dismantling of the scaffold, the work instructions for the removal shall be prepared and submitted for approval according to the design approval procedure of the scaffold. No work instructions or safety measures are not implemented, it is strictly prohibited to dismantle the work.(2) prior to the removal of the work, the approved work instructions and construction plans shall be made to the site construction personnel. And should check the implementation of site safety measures.

- Q:What are the common rules for calculating the amount of scaffolding works

- General rules for the calculation of scaffolding:Masonry works (including building blocks) are higher than 1m when calculated by external scaffolding. Independent column height of less than 3.6m according to the core of the core of the circumference of the height of the calculation of the height of the project; the height of more than 3.6m of the column core circumference plus 3.6m multiplied by the actual height of the project to calculate the amount of masonry.

- Q:The role of the external scaffolding and the relevant provisions?

- There are many kinds of scaffolding, there are many types of scaffolding alone. According to the use, structure, decoration scaffolding scaffolding and protective scaffolding; according to the use of materials, there are bamboo scaffolding, scaffolding, metal scaffolding; according to the structure form, there are several independent bar type, frame type, bridge, hanging, hanging, pick style etc..

- Q:Which accessories are included in a movable scaffold

- (1) single specification steel pipe scaffold. It only uses a steel pipe specifications, such as steel tubular scaffolding, welded steel pipe using only 48 * 3.5.(2) scaffold with various specifications of steel pipe. The utility model is composed of two or more steel pipes of different specifications, such as a door type scaffold.(3) steel scaffolding. As to the steel pipe, and combined with other type of steel pieces composed of scaffolding, such as the channel has a base in the backwater or scaffolding, connecting steel scaffolding and so on.

- Q:Was thinking of getting one. How much do they cost?

- Only a professional piercer can decide if your ear can handle and industrial piercing. Consultations are free and I highly recommend booking one before you get the piercing. Mine was $70, but my regular piercer does them for $50. It just depends on what shop you go to.

- Q:What's the film where gene Kelly dances on scaffolding? And at a gym?

- I think it's Living in a Big Way.... I could be wrong...

- Q:Salt doesn't really make any different when cleaning infact I think it makes more dried skin to get stick on the bar. My side piercing is fine but the one closest to my eye is painful when pushed or touched I think this is because I accidentally sleep on it without realising. It's red but it has no lump around the piercing is it infected or is it just trying to heal?

- problematic problem. browse at search engines like google. this could help!

- Q:Bracket cast-in-place beam bracket must use bowl buckle scaffold, can not use fastener type scaffolding, there is no mandatory requirements, or specification file requirements!

- No mandatory provisions.JGJ1622008 construction formwork safety technical specifications, is the latest specification

- Q:three examples of scaffolding, thanks

- As long as you're on the internet, why not just Google examples of scaffolding rather than expecting someone on YA to do your homework for you?

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cuplock Scaffolding System As10.8 Q345 for Supply CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords