Cup Lock Scaffolding Cuplock System for Construction Formwork Building CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Cup Lock Scaffolding Cuplock System for Construction Formwork Building

Type: Heavy Section Steel

Forming: Welding Products

Standard:

Member:

Trademark:

Connection Form:

Carbon Structural Steel:

Residential Wall Structure:

Type of Steel For Building Structure:

Bs1139, En74 Standard:

Export Markets:

Descriptions of Cup Lock Scaffolding Cuplock System for Construction Formwork Building

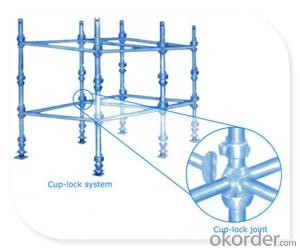

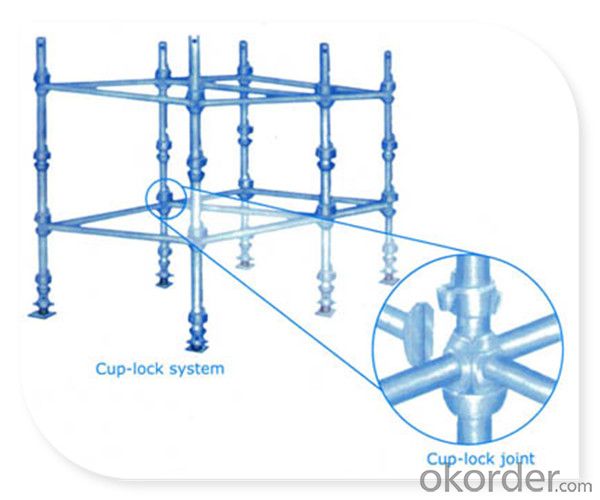

Cuplock is a kind of multi-purpose and versatile modular system scaffolding, suitable for access and formwork support in all types of construction of building & civil engineering projects, offshore projects, etc. This complete galvanized Cuplock system is probably the fastest and most widely preferred scaffolding system. It has flexible erection as straight, curved or circular configuration for both access and support purposes.

Futures of Cup Lock Scaffolding Cuplock System for Construction Formwork Building

Multi-functional-with the universal joint and fully interchangeable components, the cuplock system can be used in most construction projects for both formwork and access. It is very versatile and diverse. Use in the shipping industries, oil and gas and aviation industries.

Versatile-Verticals are assembled with horizontals and diagonals using secure fixed cup connections. Its versatility has a distinct advantage to conventional scaffolding methods. A positive & ridged connection of four units is achieved in one single action. The cupock system is very cost effective and can be erected safely and quickly.

Time saving-cuplock scaffold is the solution for temporary structures Performance stages. Small teams can erect it safely and quickly.

Economical-Easily assembled system scaffold saves time and labor costs.

Durable-All components are hot dip galvanized and manufactures to international standard.

Easily Stored-Individual pipe elements can be packed in bundles for easy storage and transportation. For returns, material can be packed in steel racks.

The Main Components of Cup Lock Scaffolding Cuplock System for Construction Formwork Building

Verticals

Description

Material

kg/pc

Article No.

9'10" Vertical 3.00m

Q345 φ48.3×3.2

16.90

SC1001 3000

8'2" Vertical 2.50m

Q345 φ48.3×3.2

14.20

SC1001 2500

6'6" Vertical 2.00m

Q345 φ48.3×3.2

11.60

SC1001 2000

4'11" Vertical 1.50m

Q345 φ48.3×3.2

8.90

SC1001 1500

3'3" Vertical 1.00m

Q345 φ48.3×3.2

6.20

SC1001 1000

1' Vertical 0.50m

Q345 φ48.3×3.2

3.50

SC1001 0500

Horizontals

Description

Material

kg/pc

Article No.

10'0" Horizontal 3.05m

Q345 φ48.3×3.2

11.80

SC1002 3048

9'0" Horizontal 2.74m

Q345 φ48.3×3.2

10.70

SC1002 2743

8'2" Horizontal 2.50m

Q345 φ48.3×3.2

9.80

SC1002 2500

7'0" Horizontal 2.13m

Q345 φ48.3×3.2

8.40

SC1002 2133

6'6" Horizontal 2.00m

Q345 φ48.3×3.2

7.90

SC1002 2000

6'0" Horizontal 1.83m

Q345 φ48.3×3.2

7.20

SC1002 1828

5'11" Horizontal 1.80m

Q345 φ48.3×3.2

7.10

SC1002 1800

5'0" Horizontal 1.52m

Q345 φ48.3×3.2

6.10

SC1002 1524

4'11" Horizontal 1.50m

Q345 φ48.3×3.2

6.00

SC1002 1500

4'1" Horizontal 1.25m

Q345 φ48.3×3.2

5.00

SC1002 1250

4'0" Horizontal 1.22m

Q345 φ48.3×3.2

4.90

SC1002 1219

3'6" Horizontal 1.07m

Q345 φ48.3×3.2

4.30

SC1002 1067

3'3" Horizontal 1.00m

Q345 φ48.3×3.2

4.10

SC1002 1000

3'0" Horizontal 0.91m

Q345 φ48.3×3.2

3.80

SC1002 0914

2'11" Horizontal 0.90m

Q345 φ48.3×3.2

3.70

SC1002 0900

8'0" Horizontal 2.44m

Q345 φ48.3×3.2

9.50

SC1002 2438

1'10" Horizontal 0.57m

Q345 φ48.3×3.2

2.40

SC1002 0600

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q:I want to get a scaffolding piercing, but i just wanna know some information.. past experiences etc. So far i have two lobe piercings on both ears and the pain wasn't too bad, but i've never had a piercing on the upper ear. How much will it cost? (I live in the UK) Just some information i guess (: thanks

- I have two lobe piercings on both ears, two cartilage piercings and an industrial that i got five months ago. I was expecting my industrial to be very painful but it wasn't that bad (i have a high pain tolerance though) its a bearable pain. Like all other piercings the healing process is the worst part and still when i bump it (like when im doing my hair) it hurts like a B****! lol. And don't play with it alot when you first get it, it causes scar tissue bumps. Use H20cean spray or you can do 1/4 tsp of sea salt and 1 cup of water to help heal it. The healing time is long, 4 months to a year. I paid $65 dollars in the us idk how much that is UK. It was definitely worth it though! Go for it :)

- Q:THIS METAL SCAFFOLDING IS CONNECTED TO EARTH.Need 2 more questions to be answered:1.Is he going to be electrocuted if he wasn't holding the metal scaffolding?2.will the current flow through him or through the wire in both cases?

- First of all, are you working with AC ( alternating current - like a house) or DC ( direct current - like a car)? Assuming you are working with AC, then: Which wire are you holding? This again is assuming 120 vac - Bare copper ( ground) White ( neutral ) or Black ( Hot ) If you have a bare copper ground wire or the White insulated wire you will be fine. If you have the Black insulated wire in your hand then you are going to have a bad day. Yes to the first question Yes to the second question ( I would hope he was smart enough to let go before being too badly zapped) Both is the answer to the third question, as the person is basically an extension of the circuit - being burnt up - until he touches earth (ground) allowing the current to seek ground. All in all I would say leave any exposed wires alone until you have a professional with a multi meter check it out first. If this is in a commercial ( business) setting the voltages are much higher, not to mention it is most likely 3 phase - so watch out. All colors are referenced for the United States.

- Q:For the current stage of China's construction should not strengthen the specific meaning of scaffolding and support by way of the scaffolding and support the specific distinction and significance

- In order not to be involved in the whole system due to local errors, the scaffold must be separated from the formwork support, forming a stable system.

- Q:What could you do with 100,000 jumbo cotton balls, 50 gallons of honey, and three story scaffolding?

- ummmm oh i got a good one i hope and that is to build the world's largest bee's hive. plus they make more honey and i would have tons of money, pretty sweet isn't it.

- Q:What are the requirements for acceptance of external scaffolding? Want to know before

- 7, scaffolding erection should be higher than the top of the building or the operating surface of 1.5m or more, and add enclosure. 8, the erection of the scaffolding on the steel pipe, fasteners, foot board and connection points shall not be arbitrarily removed. When necessary, the construction site must be approved by the person in charge of the site and take effective measures. 9, the use of scaffolding, the site should be responsible for the organization of inspection and acceptance, acceptance and fill in the inspection form before use. In the construction process should be professional management, inspection and warranty, and periodic settlement observation, found abnormal should take timely reinforcement measures.

- Q:A scaffold is constructed by placing two supports under a 13 ft, 9 in (a) board weighing 84 lbs. The supports are each 2 ft, 8 in (b) from their respective ends. Two painters stand on the board; one weighs 158 lbs and stands 4 ft, 11 in (c) from the left end of the board. Where must the 222 lbs painter stand so that each support carries the same weight? (express your distance in feet from the right end of the board (d).)please help!! thanks(:

- Total weight = 222 + 158 + 84 = 464 lb So, each support must carry 232 lbs Working in inches: Take moment about Right hand end Board is assumed to be uniform - CG is at the center (232 x 32) + (232 x 133) = (158 x 106) + ( 84 x 82.5 ) +(222 x d)7424 + 30856 = 16748 + 6930 + 222d 222d = 14602 d = 65.77 inches Distance of 222 lb painter should be 5ft 5.77inches from Right end

- Q:I have to write a 1 page commentary on a geographical issue for school, and, I've never done that before.Could someone please tell me or link me to a very simple 'writing commentary' scaffold for beginners?Please?Thankyou :)

- To know about College and university! log on to alumne /

- Q:Okay so I got a scaffold piercing about 5 days ago now. I've been cleaning it with Claire's piercing stuff. What I do is I pour it onto a little bit of loo roll and squeeze it all out on where the holes are. I have not been twisting it at all, but my friend told me that I should soak it in warm salty water and twist it twice a day. I have no idea what to do now as I have researched it and some people say that I shouldn't twist it because it will drag more bacteria into it and could get it infected. Also I have massive scabs around both ends of the bar, I've tried to pick them off as they are pretty uncomfortable, but it didn't work as they are rock solid, so how do I get these off? I have no idea what to do, my piercer didn't say anything about twisting it just cleaning it twice a day. Oh and if it helps I'm 13:) Thanks. X

- Why are you using Claire's crap? You need to be doing sea salt soaks twice a day for 5-10 minutes each soak with 1/4th of a teaspoon of non-iodized sea salt to 8oz of hot water. Don't twist them as that drags in crust and bacteria and tears up the inside of the piercing. Stop trying to pick stuff off from your ear and go have a reputable piercer check out the scabbing, it could be crust it could be something wrong. If your piercer didn't tell you to do sea salt soaks to keep it clean go to a better piercer.

- Q:The outer hanging scaffold board 12 embedded parts embedded in the crack?

- Is the pre embedded parts installation (burial) component hidden in the works inside. Is placed in the structure of casting fittings, for masonry superstructure when the lap. In order to facilitate the installation of engineering equipment based on external fixation. Most embedded parts made of metal, such as steel or iron, can also be used in wood, plastic and other nonmetallic rigid materials.

- Q:For indoor use of mobile scaffolding safety construction plan! Four support points with four pulleys with brake!The construction scheme of scaffolding safety belt for indoor high Jiqiu braking pulley, for about 12 meters of buildings, indoor emergency please heroes!

- All kinds of scaffolding engineering construction programGeneral requirements for 5.2.1 scaffolding settings and use general requirements for scaffold framing and setting requirementsThe design of the frame of the scaffold shall take full account of the requirements for the use of the project, the various conditions and factors for its implementation, and shall comply with the following requirements:Frame dimensions

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cup Lock Scaffolding Cuplock System for Construction Formwork Building CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords