crack-resistant outdoor co-extrusion wpc decking/plastic composite decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Features of the Co-extrusion WPC Decking:

1. Recyclable, Eco-friendly, saving forest resources

2. With the look of the natural wood, but less timber problems

3. Moisture/water resistant, less rotten, proven under salt water condition

4. Barefoot friendly, anti-slip, less cracking, less warping

5. Requires no painting, no glue, low maintenance effort

6. Weather resistant, suitable from minus - 40 to 60 centigrade degree

7. Termites and insects resistant, and moldy-proof

8. Easy to install and clean

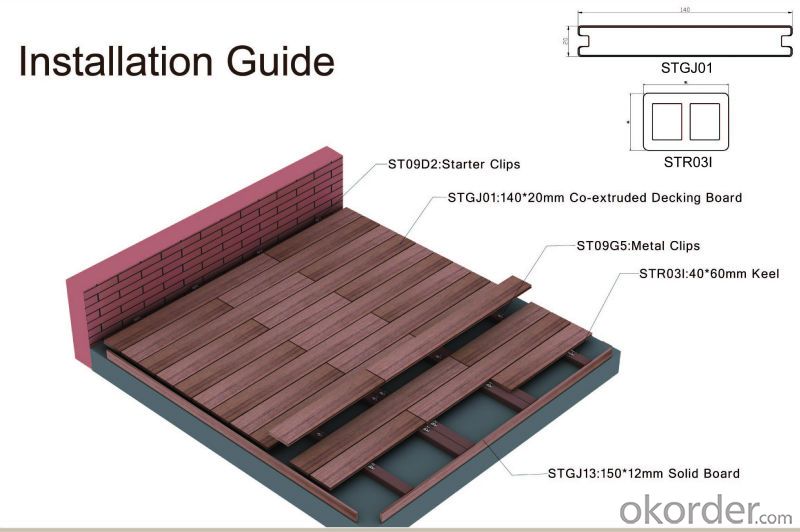

Specification of Co-extrusion WPC Decking:

component | 30%HDPE(Grade A Recycled HDPE) 60%bamboo/wood fiber component 10%chemical addatives New material capped outside |

Size | 140X20mm |

Design | Solid decking |

Length | 2.9m/pc standard length, also from your required |

Surface treament | original, sanded, brushed |

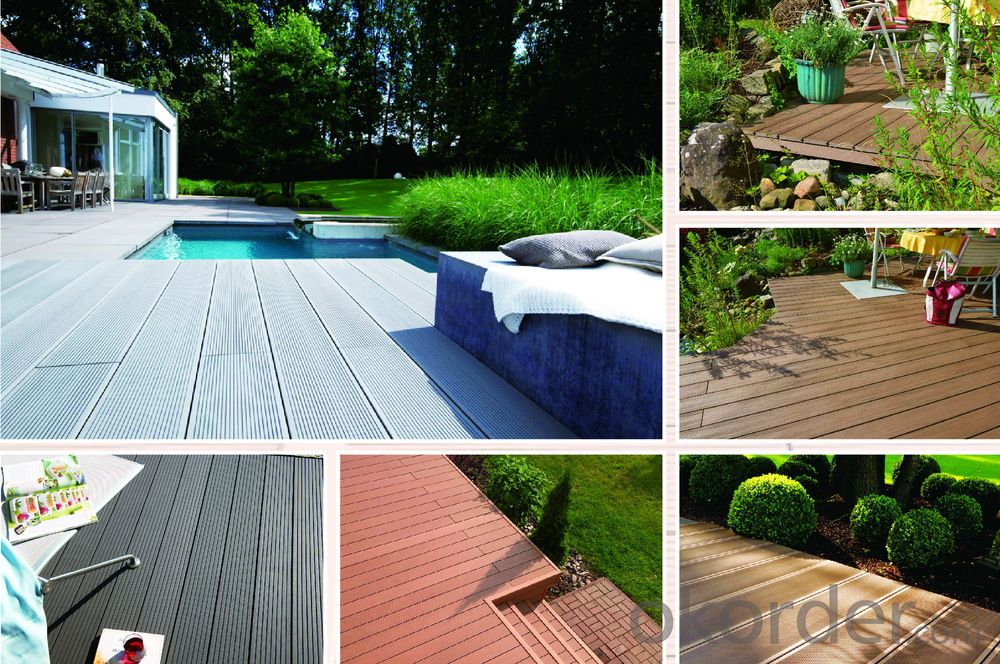

Color available | 5 regular colors for choice ( IPE,Walnut,graystone,Cedar,Rosewood) and we can adjust the new color according to the order requirement |

Cerfiticate | ISO9001, ISO14001, CE, FSC Certificate,"REACH"Test Reports by SGS; Intertek Test Report by ASTM standard..etc. |

Features: | 1.MORE STABLE “0” water absorption,”0’rotten,”0”mouldy.Less thermal expansion,less color fading. 2.MORE NATURAL Gradual change color,No scratches,No stain,No shinning,Deep wood grain with rough surface and vivid colors similar to real wood. 3.LONGER LIFETIME More than 25 years life time&Limited Warranty for 15 years. 4.Low Maintenance: Simple water is more than enough. |

Images of Co-extrusion WPC Decking:

FAQ of Co-extrusion WPC Decking :

1. Available Colours?

5 regular colors to choose ( IPE,Walnut,graystone,Cedar,Rosewood )

2. How to Install?

3.Packaging & Delivery?

Packaging Detail | 112pcs per pallet, 16pallets per 20ft, 24 pallets per 40ft. pallet size:290x105x1375px |

Delivery Detail | 3-4 weeks per 20ft |

- Q:Q: how to clean the composite floor dirty

- You fancy is what to get things, generally have the oil washed with detergent on the line, because the composite floor is very wearable, you can also ding dumplings dumplings sacrifice twitch yong to brush with a brush is also It does not matter, but do not use thinner, especially the board that made the paint.

- Q:Solid wood flooring is not easy to scratches?

- Multilayer solid wood and solid wood flooring test wear resistance method and strengthen the floor is different. Multi-layer solid wood paint quality is measured by the loss of paint film, that is, with 180 mesh grinding wheel, weight 500g and the film surface relative friction, the national standard paint mill loss of ≤ 0.08g / 100r, so When you buy, you can place the floor board oblique light, from the end of the board to observe whether the film is uniform and full, with or without wavy indentation and so on. High-quality solid wood composite flooring surface coating more uniform. You in the course of the use of scratches, there may be in the course of your carelessly scratched by other sharp objects, or the floor of the paint itself did not do? If that is the case, you are looking for manufacturers. Also give you some way to deal with scratches: 1 If the surface of the paint film is not bad, just a little mark, after cleaning, polished wax can be used directly polished. If the floor paint film damaged or exposed white, can be used No. 400 water sandpaper dipped in soap and water to polish, and then the chicken feast of the darffs of the immortal clever, to be dry, the local complement color, color dry, and then brush a paint, After drying for 24 hours, polish with 400 water sandpaper and then wipe the wax for polishing. 2 scratch depth is different, the repair method is also different. The best solution is very shallow scratches, with 0 metal friction can be solved with oil friction. (Very soft metal cotton, without leaving scratches) deep scratches, you need to find a professional to repair. The usual way is to expand the scratch to the appropriate width, putty, and then fill the paint.

- Q:Just the floor of the composite floor, the floor of the elephant, paved, the other is ok, but in the floor and wardrobe where the transfer, stepped up a little creaky sound Why? Is there a way to solve it? (Feeling tread on the raft stare destroy the slander frost frost cream that place, the floor a little Alice, do not know what the reason, a step on the go a little, heel and recovery) more

- Composite floor sound is due to the floor lock slotted too loose or too tight caused by the floor after the floor due to the situation is not absolutely flat, in the tread when the slight floating caused by the floor seams at the friction caused by friction, which Is due to the floor in the production failed to achieve accuracy, in the installation did not meet the standard requirements of the installation caused by sizing. Solution: the original floor carefully open, because it is not plastic, so in addition to the beginning of the demolition of a few pieces of the floor, the other will not have any effect, will remove the floor in situ, and then re-installed , Remember to play the floor special plastic, re-installed after there will be no voice. Composite flooring is one of the flooring. But the composite floor was artificially changed the natural structure of the floor material, to achieve a physical performance in line with the requirements of the floor. Composite flooring in the market often refers to strengthen the composite wood flooring, solid wood flooring.

- Q:Multi-layer solid wood composite floor light storage dog Fuhua, known as both solid wood flooring elegant noble comfort, but also both strengthen the composite floor easy to take care of, anti-wear and other advantages, a great come from behind the trend, in order to Find out why the reason to ask. More

- Multi-layer solid wood composite floor 窢 窢 促 段 讵 light storage dog Fuhua, known as both solid wood flooring elegant noble comfort, but also both strengthen the composite floor easy to take care of, anti-wear and other advantages, a great come from behind the trend, in order to Find out why the reason to ask. More

- Q:How to install video on composite flooring

- Install the frequency

- Q:Good quality composite floor where to buy?

- I think the quality of the best quality is the floor of the floor, the abundance of composite floor, the abundance of the real raft Gong destroy the siege of locusts rubbing Wei Shan wood composite floor, so the abundance of the floor is really very good great.

- Q:I bubble two different brands of composite flooring, soak a night, its edge has a centimeter width of the bubble up, come up with drying, there is a piece of recovery to the original state, there is a piece has been restored, ask you master, Is all the laminate flooring will be the case, or that the two floors are not good, like the kind of big brand of water soaked after the water will not appear such a situation, there is no one tested ah? Please test friends Recommend a few shocks Museum can be Jiu Jiu turtle snow you feel good after the test brand. Thank you! More

- Well, you are doing right, soak in the water they will be swollen, not see the muscle museum can be Jiu Jiu turtle snow out what, the floor is good or bad to come out to see, that is, after drying will not Will be deformed, can not recover the piece is not good.

- Q:How to install the floor of the composite method

- In accordance with the counterparts on the line, but you need special cutting tools and splicing tools, it is best not to own equipment, very dirty and very troublesome

- Q:Will the floor of the floor be poisonous?

- Composite wood flooring environmental standards, but there really do this harm. Composite wood flooring is usually 3 layers, 5 layers or more. Usually solid wood multi-layer composite, as well as non-solid wood multi-layer composite. Layer between the use of glue bonding. To warm the ground will promote the glue and woodworking boards and other artificial wood in the distribution of harmful substances. So if the home to consider the warm, it is best to use three layers of solid wood flooring, less glue content, solid wood does not exist harm.

- Q:I want to choose composite floor price of 30-40 yuan or so (quality to go to), which brand of suitable for some?

- If only the floor price, what is not the package, even the freight is not included, so that the floor can be used at home. If it is packaged with other shipping costs, installation costs, etc., then the floor is not recommended to buy. Poor quality, used at home after a problem. For a floor, think of moving furniture, and then re-shop, energy and costs are high. [Bell floor, home, dream starting point]

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

crack-resistant outdoor co-extrusion wpc decking/plastic composite decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords