CPG-6F Automatic In-line Capping machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Product Details

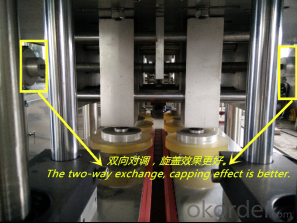

JCP-6A In-line Structure Capping Machine is making up with cap sorter, cap falling rail, bottle-tightening structure and capping wheels. By the tightening of the belts, the bottles finish the movement of cap scratch, push and capping. It applies to the capping of round and flat bottles. This capping machine is with easy structure and adjustment. When changing the bottle type, you do not need to change the spare part, only adjustment is enough.

2、Features

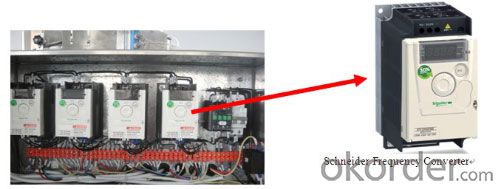

2.1 The whole machine uses Schneider brand which can make sure the stability of the machine.

2.2 A cap sensor is installed in the cap hopper. When there is not enough cap, the elevator will start working to make sure providing caps.

JPACKS Centrifugal Cap Sorting Bowl is also a great solution for high speed sorting and noise reduction for both flat, non-flat and specialty caps.

Specifications:

Custom tooling available

Optional diameters to accommodate varying cap sizes and types

2.3 Use a handle to adjust the height and tight of the machine,stable and reliable.

2.4 A mirror is installed to check the state of caps.

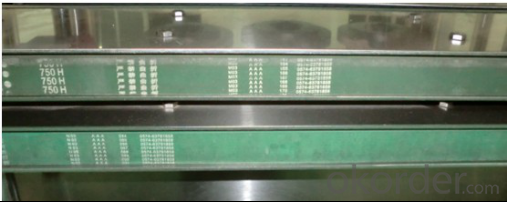

2.5 The tightening belt can last for a very long time.

2.6 The capping wheels with new material can last for a very long time.

2.7 Intectual blow back lid system

Intectual checking back lid, high-speed magnetic valve rejector, solving the noise polluction, large comsumption of air and low qualified rate. Convenient adjustment.

3、Main Technology Parameter

3.1 Capacity:≤8000 Bottles/hour

3.2 Applicable Bottle Diameter:Φ35-96mm Bottle height: 80-230mm

3.3 Cap Specification:Φ12-50mm Cap height: 15-40mm

3.4 Air Pressure:0.5~0.7 MPA

3.5 Power Source:~220V、50HZ

3.6 Power:2KW

3.7 Weight:about 650Kg

3.8 External Dimension:2000×950×2100mm(L×W×H)

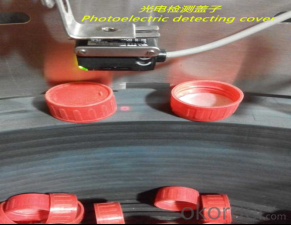

4、Images

FAQ

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

- Q:What's the difference between the materials used in kraft paper packaging?

- The whole paper pulp kraft paper packaging: tension is very good, do not pull off, the color will be very uniform, is also very resistant to wear if you need outside packaging printing LOGO what, it can use kraft wrapping paper wood pulp, wood pulp and kraft wrapping paper printed very well.

- Q:What's the function of pearl cotton packing material?

- Pearl cotton packing material has many advantages, such as waterproof, moisture-proof, shockproof, sound insulation, thermal insulation, good plasticity, toughness, recycling, environmental protection, strong impact resistance, and so on. It also has good chemical resistance. Is the ideal substitute of traditional packaging materials.

- Q:Is the antistatic value of PS material (or other packing material) as small as possible?

- Not necessarily. This needs to be decided in terms of specific areas of use and requirements.The so-called antistatic refers to reach 10 between the 7-10 sides.And the 1-6 side of the 10 is generally referred to as electrical conduction.

- Q:What are biodegradable packaging materials?

- Biodegradable plastics is added in the production process of additives (such as starch, modified starch or other vitamins, photosensitizer, biological degradation agent), decreases its stability in the natural environment, easily degradable plastics.

- Q:Does the desiccant belong to the packing material?

- Many used desiccant is involved in metal industry, some equipment and parts in the transport process, to prevent corrosion, reduce the humidity inside the packaging, the possibility of reducing dew temperature, the general formula is the packaging materials used.

- Q:What material is the vacuum packing bag, please?

- Vacuum packaging is a general term for flexible packaging composite membrane products. If the temperature is different, there will be a lot of division: there is less than 100 bactericidal, and some need 100 degrees of sterilization, and 121 degrees and 135 degrees. Of course, there is also room temperature, the choice of this temperature under the condition of the sterilization method is irradiation sterilization. And also consider the content and weight of the package to determine the reasonable use of the packaging materials. There is no static, and the right is the best.

- Q:How to prevent the use of packaging materials during production without error?

- Strengthen supervision, special packaging materials can be set up straight personnel.Management must be one to one or one to many, not many to one management. Otherwise easily confused.Do a good job of late entry, ensure that products correspond to their place.I hope I can help you.

- Q:What is the charge for packing materials?

- It belongs to the productive circulation cost: the packing cost, storage and keeping charge, loading and unloading fee, finishing fee and so on,

- Q:What's the difference between bulk food and prepackaged food?

- Is a small workshop to provide containers, that is, pre packaged food, is to take their own containers to buy, that is, bulk food

- Q:What can I do instead of the carton packing now?

- From the performance point of view, the permeability is good, waterproof and hardness is relatively poor, and can be disassembled, folded, easy to store. (if it is plated with plastic film box, waterproof and hardness will be improved, ventilation decreased)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CPG-6F Automatic In-line Capping machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords