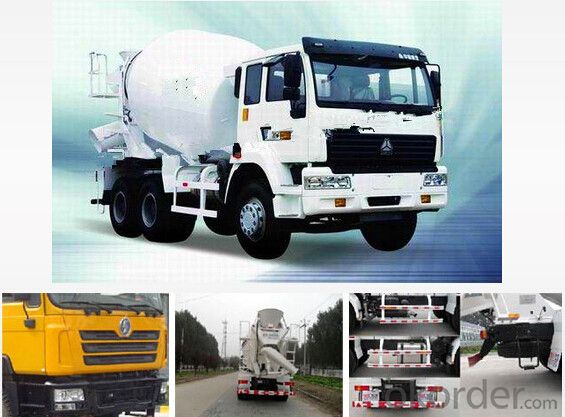

Concrete Mixer Truck with Good Performance

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Name: CMAX Concrete Mixer Truck with Good Performance for Hot Sale

1. Specification

Model: ZJV5255GJBLYCA1

Overall size (mm) 10130(L)*2500(W)*3990 (H)

Tank body dimension(mm) 5790*2300

Wheel base (mm) 4300+1350

Tread f/r (mm) 2050/1830

Max. Speed (km/h) 88

Chassis

Manufacturer China FAW Group Corporation

Model CA1250P66K2L2T1S2E

Steering System Recirculationg ball type integrial hydraulic power steering system

Transmission Manual

Brake System Dual circuit air-pressure braking system

High pressure oil pump | ARK pump |

Hydraulic motor | ARK motor |

Reducer | PMB7.1sp |

Water supply system | Water supply by air pressure (450L water tank), homemade sprinkler. |

Air-condition | FAW special air condition |

Engine | |

Model | CA6DL2-35E3 |

Max. Power (hp) | 367 |

Engine type | L6,water-cooled, supercharged inter-cooling diesel engine |

Fuel type | Diesel oil |

Tank body parameter | |

Mixing volume(m3) | 12, optional for 6-12m3 |

Feeding speed | More than or equal to 3m3/min |

Unloading speed | More than or equal to 2m3/min |

Discharge residue rate | Less than 0.5% |

2. Application

Concrete Container and delivery.

3. Package

Put into containers.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce Concrete Mixer Truck with Good Performance according to customers request?

A4: Yes, we can produce Concrete Mixer Truck with Good Performance for Hot Sale according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: We have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

- Q:What is the driving license for a concrete mixer truck?

- B2, you can do it directly. But it must be 21 years old and must be taught in permanent residence. The temporary residence is limited to the C series. The tuition fee for Beijing is 2,800 to 3100.

- Q:What is the normal speed in the transportation of the concrete mixer

- In the case of idle speed (engine speed of 600 r/min) generally feed mixing every 4 r/min, when discharging at around 6 r/min, the gas engine speed from 1500 to 2000 r/min when the hydraulic pump and motor mechanical efficiency is highest, feed mixing around 10 r/min, when discharging 12 to 14 r/min. Speed is adjustable, through adjust the driving torque of each point, can make the speed increase or decrease, when the stirring speed too fast will affect the service life of the hydraulic system, general stirring speed in the process of transportation for the 3 revolutions per minute.

- Q:What is the meaning of the word "concrete" in the concrete mixer jar?

- The "concrete" means "concrete" means "concrete". This is not to say that the car must print these two words, depending on the company. But I know the name of the company and the company.

- Q:Does it affect the ease of mixing too long?

- First, the quality is stable and controllable Second, there is less pollution of the environment Three, the energy conservation The mixer is required for both shipping distance and mixing speed, a bit technical

- Q:What can be done to remove the concrete from the concrete mixer truck

- It consists mainly of agitator and auxiliary supporting parts. Mixing drum of concrete loading container, it is made from high quality wear-resistant steel sheet, in order to be able to automatic loading and unloading of concrete, the lining welding spiral blade with special shape. When the concrete moves in the direction of the blades, it is mixed and stirred in the process of increasing and turning. In the process of feeding and transportation, the mixing cylinder is turning, the concrete is moving in the blade, and the mixing cylinder is turned and the concrete is removed out of the blade. The rotation of the mixer is guaranteed by the hydraulic actuator. The load is 3-6 cubic meters. Of commonly used concrete mixer truck passed by the car engine power output shaft to drive hydraulic pump, and driven by hydraulic motor with high pressure oil push the mixing barrel, loading capacity for 9 ~ 12 cubic are driven by automotive auxiliary diesel engine driven hydraulic pump hydraulic motor. The blades are the main parts of the mixing plant, and the damage or severe wear and tear can cause the concrete to be mixed. In addition, if the design is unreasonable, the concrete will be isolated.

- Q:How many cubic meters of concrete mixer transport vehicle

- Existing 3 cubic concrete mixer truck, 3.5 cubic, 4 cubic, 5 cubic, 6 cubic, 8 cubic, 9 12 cubic cubic, 10 cubic, such as specifications, can meet the different needs of customers, chassis choose well-known brands at home and abroad, oil pump, hydraulic motor, deceleration pause with American Eaton, the Italian state, and other well-known brands at home and abroad, to ensure that the vehicle performance is stable, safe and reliable.

- Q:s the collapse of four concrete mixer trucks

- The caving degree is 4 cannot be transported by concrete mixer, the slump is put into and out of the tank car. The average slump is 100 to 120mm, and it is better not to transport the concrete transporter, preferably with a construction dump truck.

- Q:What is the car for concrete

- These trucks are equipped with cylindrical agitating cylinders to carry mixed concrete. During the course of transportation, the mixer will be kept rotating to ensure that the concrete is not frozen. After the concrete is transported, it is usually used to flush the inside of the cylinder to prevent the hardened concrete from taking up space, making the cylinder volume less and less

- Q:What is the difference between a concrete mixer and a tanker?

- A special truck used to transport construction concrete; Because of its appearance, it is also commonly referred to as the tian. These trucks are equipped with cylindrical agitating cylinders to carry mixed concrete. By the automobile chassis, mixing barrel, transmission system, water supply equipment, take full power and power, before and after the mixing drum support, deceleration machine, hydraulic transmission system, material in and out of the system, operating mechanism and other parts. Due to the technical bottleneck, the domestic mixer can be made from 3m to 8m cubic meters, and the four large parts of the volume are imported. Composition: type 2 chassis, drive system, hydraulic system, frame, mixing tank, feeding system, water supply system, operating system, ladder and so on. The top of the mixing tank is mounted on the rack, and the rear end is supported by two supporting wheels mounted behind the chassis.

- Q:How does the concrete mixing truck work?

- Working principle is that by taking power device to take out car chassis power, and drive hydraulic system of the variable pump, the mechanical energy into hydraulic energy to quantitative motor, motor and drive reducer, driven by speed reducer mixing plant, for mixing concrete

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Concrete Mixer Truck with Good Performance

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords