Color Painted Aluminium Foils Used for Insulated Ducts

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of Color Painted Aluminium Foils Used for Insulated Ducts

We specialize in Blue Coated Aluminium Foils Used for Insulated Panels . Our coating include blue color, transparent color, gold color, silver color, etc.

Normally we use 1100 H22 as base coils and coated with clear epoxy, which is easily to be stuck with polyurathane and phenolic foam. Usual width include 1210mm, 1215mm, 1270mm, etc.

We have very strict inspection management including inspection for materials, inspection during production and inspection for finished goods.

Our test equipments include optical thickness gauge, cupping test machine, mettle Toledo, tensile-strength tester, busting strength tester, elongation tester, etc.

2.Main Features of Color Painted Aluminium Foils Used for Insulated Ducts

Moisture resistant

Light and easy for installation

Heat preservation

Low thermal conductivity

Durable and corrosion resistance

High heat reflection

Energy Saving

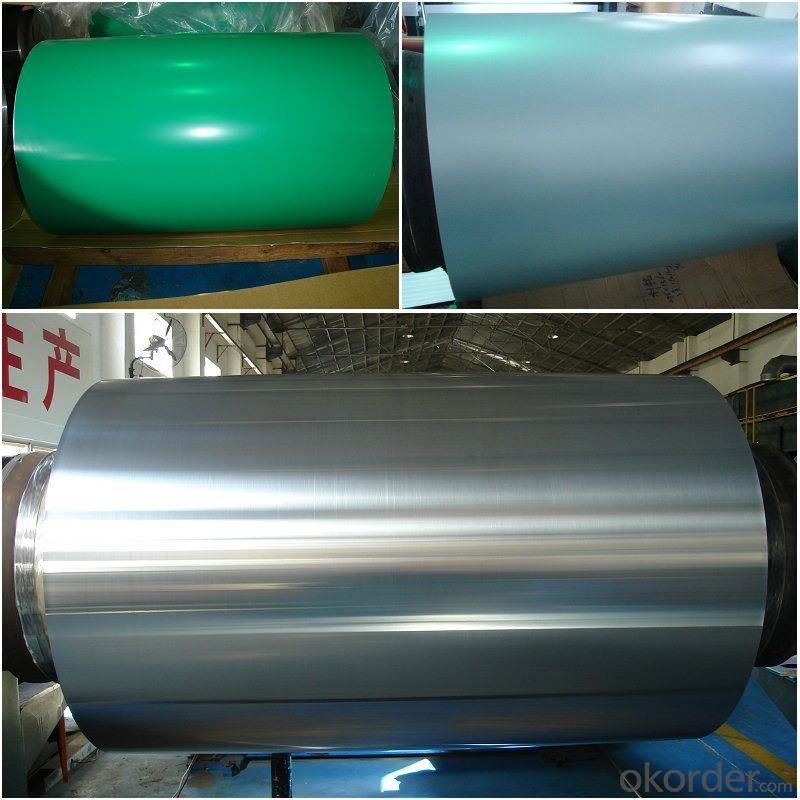

3. Color Painted Aluminium Foils Used for Insulated Ducts Images

4.Specification of Color Painted Aluminium Foils Used for Insulated Ducts

Alloy: 8011/ 1100/ 1235

Temper: O/H18/H22/H24/H26

Thickness & tolerance: 0.007-0.2mm (+/-6%)

Width & tolerance: 200mm-1650mm (+/-1mm)

Mechanical properties: Tensile strength (U.T.S) ≥ 80 MPA, Elongation ≥ 1%

Standard: GB/T3198/ASTM-B209/EN546

5.FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:My boyfriend sweats a lot and uses Mitchlum deodorant, a lot of it, under his armpits and waits til it dries to stop the sweating. I heard aluminium was bad for you, but he says natural deodorants don't work as well. What do you think?

- This is doctrine according to me, so Don't take it for absolute truth. I had a science teacher who said the aluminum in deodorant was bad for you because you have major arteries in your armpits that go to the rest of your body and it carries it there and is linked to things like alzheimers (please excuse my spelling). Then I had another teacher who said that that was complete rubbish. Aluminum is everywhere. If it was going to do that from deodorant, it would do it from a million other things. Oh, and certain deodorants work for certain people, others not so well. I actually have to switch types every once in a while because the one I use stops working. In my experience, the natural stuff doesn't work as well. So, you don't have to believe me, but you asked what I thought.

- Q:Are aluminum coils resistant to saltwater corrosion?

- Yes, aluminum coils are generally resistant to saltwater corrosion. Aluminum is known for its excellent corrosion resistance, especially in marine environments where saltwater exposure is common. The naturally forming oxide layer on the surface of aluminum provides a protective barrier against saltwater corrosion. This oxide layer acts as a shield, preventing direct contact between the aluminum and the corrosive saltwater. Additionally, aluminum coils can be further protected through various coating methods, such as anodizing or painting, which enhance their resistance to saltwater corrosion even further. However, it is important to note that prolonged or continuous exposure to saltwater can gradually degrade the protective oxide layer and may eventually lead to corrosion, although this process is typically slow. Regular maintenance and proper care can help extend the lifespan and performance of aluminum coils in saltwater environments.

- Q:What are the potential applications of anodized aluminum coils?

- Anodized aluminum coils have numerous potential applications across various industries. One of the primary uses of anodized aluminum coils is in the construction industry. They are commonly used for cladding and façade systems, as the anodized coating enhances the durability, weather resistance, and aesthetic appeal of the aluminum. Anodized aluminum coils can withstand harsh environmental conditions, such as UV radiation, saltwater exposure, and extreme temperatures, making them an ideal choice for building exteriors. Another significant application of anodized aluminum coils is in the automotive industry. The anodized coating provides a protective layer that enhances the corrosion resistance of aluminum, making it suitable for various automotive components. It can be used for trim, body panels, window frames, and other parts that require both durability and an attractive appearance. Anodized aluminum coils also find use in the manufacturing of consumer electronics. The anodized coating improves the scratch resistance, electrical insulation, and heat dissipation properties of aluminum, making it suitable for electronic enclosures, heat sinks, and connectors. Additionally, the vibrant colors that can be achieved through anodization allow for customizable designs that appeal to consumers. Due to its lightweight nature and excellent heat conductivity, anodized aluminum coils are extensively used in the heating, ventilation, and air conditioning (HVAC) industry. They are commonly used for heat exchangers, air conditioning coils, and evaporator coils. The anodized coating provides protection against corrosion caused by moisture and other environmental factors, ensuring the longevity and efficiency of these HVAC components. Furthermore, anodized aluminum coils have applications in the food and beverage industry. The anodized coating provides a hygienic surface that is easy to clean and resistant to bacterial growth. It is used for food processing equipment, storage tanks, and packaging materials, ensuring the safety and quality of the products. Overall, the potential applications of anodized aluminum coils are vast and diverse, ranging from construction and automotive to electronics and food processing. The unique combination of durability, corrosion resistance, heat dissipation, and aesthetic appeal makes anodized aluminum coils a versatile material that finds use in numerous industries.

- Q:What are the typical applications of aluminum coils in the automotive industry?

- Aluminum coils are widely used in the automotive industry for various applications due to their advantageous properties. One typical application is in the manufacturing of automotive heat exchangers, such as radiators and condensers. The high thermal conductivity of aluminum allows for efficient heat transfer, enhancing the cooling efficiency of the vehicle's engine and air conditioning system. Another common use of aluminum coils in the automotive industry is for making lightweight body panels and structural components. Aluminum is known for its low density, which helps reduce the overall weight of the vehicle. This, in turn, improves fuel efficiency and reduces emissions. Additionally, aluminum's high strength-to-weight ratio makes it ideal for impact-absorbing structures, enhancing the safety of the vehicle. Aluminum coils are also utilized in the production of electrical wiring systems and connectors in automobiles. Aluminum's excellent electrical conductivity enables the efficient transmission of electrical signals throughout the vehicle. Furthermore, its corrosion resistance properties make it suitable for use in various weather conditions. Moreover, aluminum coils find application in the production of suspension systems, such as control arms and knuckles. The stiffness and durability of aluminum help enhance the vehicle's handling and responsiveness, resulting in improved driving dynamics. In summary, the typical applications of aluminum coils in the automotive industry include heat exchangers, lightweight body panels, electrical wiring systems, and suspension components. These applications capitalize on aluminum's advantageous properties, such as high thermal conductivity, low density, excellent electrical conductivity, and corrosion resistance.

- Q:Can aluminum coils be used in wastewater treatment plants?

- Yes, aluminum coils can be used in wastewater treatment plants. Aluminum coils are commonly used in heat exchangers within wastewater treatment plants to transfer heat effectively and efficiently. They are resistant to corrosion and can withstand the harsh environment of wastewater treatment processes.

- Q:What are the different widths available for aluminum coils?

- The different widths available for aluminum coils can vary depending on the manufacturer and specific application. However, the most common widths for aluminum coils range from as small as 12 inches up to 60 inches or more. These widths are typically measured in inches and can be customized to fit specific industrial or commercial needs. The selection of the appropriate width for aluminum coils is crucial as it directly affects the efficiency and effectiveness of various processes such as manufacturing, construction, and transportation. Additionally, the width of aluminum coils can also impact the cost and availability of the material, making it an important consideration for both buyers and suppliers.

- Q:What is the hardness of aluminum coils?

- The hardness of aluminum coils can vary depending on a few factors such as the specific alloy used and the tempering process applied. Generally, aluminum coils have a relatively low hardness compared to other metals. Aluminum is known for its lightweight and malleable properties, making it easy to bend and shape. However, through various heat treatment processes like annealing or cold working, the hardness of aluminum coils can be increased to meet specific requirements. It is important to note that the hardness of aluminum coils may also vary depending on the intended application and the desired level of strength and durability.

- Q:Are aluminum coils easy to bend and shape?

- Yes, aluminum coils are relatively easy to bend and shape. Aluminum is a malleable metal, which means it can be easily deformed under compression without breaking. This property makes it highly suitable for shaping and forming into various shapes and sizes. Additionally, aluminum coils can be manipulated using different techniques such as rolling, bending, or pressing, allowing for a wide range of applications in industries such as construction, automotive, and manufacturing. However, the ease of bending and shaping aluminum coils may also depend on the specific alloy and thickness of the coil. Thicker coils may require more force and specialized equipment for shaping, while certain alloys may have different levels of malleability. Overall, aluminum coils offer a versatile and relatively easy-to-work-with material for bending and shaping purposes.

- Q:Just want to know for any boat builders out there. I have been told by my local paddling store that there are no aluminum kayaks. Why couldn't i build one? it cant be weight, I would build the frame from 1/2 inch square aluminum tubing and the body out of 1/32 high grade sheeting. So why does something like this not exist?

- Aluminum Kayak

- Q:Are aluminum coils suitable for manufacturing cookware?

- Yes, aluminum coils are suitable for manufacturing cookware. Aluminum is a popular choice for cookware due to its excellent heat conductivity, which allows for even heating and efficient cooking. It also has a lightweight and durable nature, making it easy to handle and long-lasting. Additionally, aluminum is resistant to rust and corrosion, making it an ideal material for cookware that is frequently exposed to water and heat. However, it is important to note that uncoated aluminum cookware may react with certain acidic or alkaline foods, leading to a metallic taste. To overcome this, many aluminum cookware manufacturers use non-stick coatings or anodized finishes to prevent food reactions and improve the durability of the cookware. Overall, aluminum coils are a suitable material for manufacturing cookware, but it is essential to consider the specific requirements and coatings needed for different types of cookware to ensure safety and optimal performance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Painted Aluminium Foils Used for Insulated Ducts

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords