All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the safety considerations when operating aluminum coil processing equipment?

Some safety considerations when operating aluminum coil processing equipment include proper training and understanding of the equipment, wearing appropriate personal protective equipment, regular maintenance and inspection of the equipment, following proper operating procedures, ensuring a clear and organized work area, and being aware of potential hazards such as sharp edges, moving parts, and electrical risks.

How do you assess the surface quality of aluminum coils for specific applications?

To assess the surface quality of aluminum coils for specific applications, several factors need to be considered. Firstly, a visual inspection is conducted to check for any visible defects such as scratches, dents, or uneven surfaces. Additionally, the thickness and uniformity of the coating or finish on the coil are examined. Surface roughness measurements can be taken using instruments like profilometers to ensure the desired smoothness. Adhesion tests may also be performed to verify the coating's bond strength. Ultimately, the assessment involves a combination of visual inspection, dimensional analysis, and testing methodologies to ensure the surface quality meets the requirements of the intended applications.

What is the role of aluminum coils in the automotive radiator industry?

The role of aluminum coils in the automotive radiator industry is to efficiently transfer heat from the engine coolant to the surrounding air. These coils are a crucial component of the radiator as they provide a large surface area for heat exchange, allowing for effective cooling of the engine. Aluminum coils are lightweight, corrosion-resistant, and offer excellent thermal conductivity, making them an ideal choice for radiator construction.

Are there any restrictions on the international trade of aluminum coils?

Yes, there are restrictions on the international trade of aluminum coils. These restrictions can vary depending on the country and the specific regulations in place. They may include trade barriers such as tariffs, quotas, or embargoes imposed by governments to protect domestic industries or address national security concerns. Additionally, international trade agreements and organizations may also impose certain rules and regulations on the trade of aluminum coils to ensure fair competition and adherence to global trade standards.

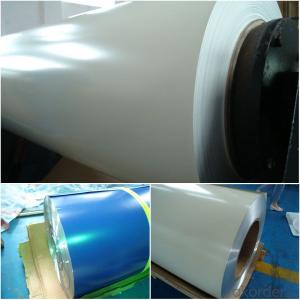

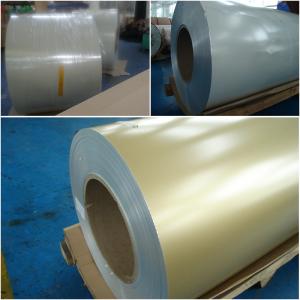

Wholesale Aluminum Coils from supplier in Colombia

Whether you are in the construction, automotive, or packaging industry, our Aluminum Coils are tailored to meet your specific requirements. We offer a wide range of grades, thicknesses, widths, and surface finishes to ensure that you find the perfect solution for your application.

In addition to supplying high-quality Aluminum Coils, we also provide exceptional sales, quotes, and technical support services. Our team of experts is dedicated to assisting you throughout the procurement process, from selecting the right product to providing guidance on installation and maintenance.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the backing of a financially stable and reputable organization. This enables us to offer competitive pricing and reliable delivery of Aluminum Coils in Colombia.

With years of market development in Colombia, we have established strong relationships with local suppliers, manufacturers, and distributors. This allows us to offer valuable insights and expertise, ensuring that you make informed decisions for your projects.

At [Company Name], we are committed to providing exceptional products and services. Contact us today to discuss your Aluminum Coils needs in Colombia and experience a seamless procurement process with us.

In addition to supplying high-quality Aluminum Coils, we also provide exceptional sales, quotes, and technical support services. Our team of experts is dedicated to assisting you throughout the procurement process, from selecting the right product to providing guidance on installation and maintenance.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the backing of a financially stable and reputable organization. This enables us to offer competitive pricing and reliable delivery of Aluminum Coils in Colombia.

With years of market development in Colombia, we have established strong relationships with local suppliers, manufacturers, and distributors. This allows us to offer valuable insights and expertise, ensuring that you make informed decisions for your projects.

At [Company Name], we are committed to providing exceptional products and services. Contact us today to discuss your Aluminum Coils needs in Colombia and experience a seamless procurement process with us.