Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

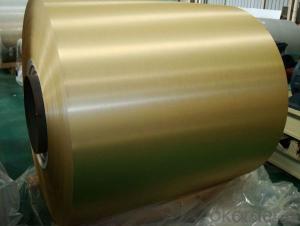

5. Image of Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

6. Package and shipping of Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Aluminum extrusions are bars made with hollow cavities that allow each to be joined easily, using special connectors. The primary difficulty when painting aluminum extrusions centers on the fact that they are nonporous and durable. Each of these traits creates a complication of its own.

- Your question supposes that you need to Paint the Aluminum Extrusion. The more common thing to do is to Anodize the extrusion. This process coats all surfaces with a hard durable coating. There are several colors available. Actually It's common to use Urethane's to paint Aluminum and the primer isn't simply made for metal, but is specifically for Aluminum. A lot of Airplanes are coated every day in this manner. Methods for coating the insides of tubing have been used for a very long time. You basically fill the tube with primer or coating then drain the excess out (dip method) and difficult shapes can be powder coated or electro static coated. Extrusions can be roller coated after cleaning, vinyls work very well with out priming. Think Toothpaste tubes.

- Q:How do aluminum coils compare to zinc coils in terms of durability?

- The durability of aluminum coils and zinc coils is influenced by their different properties. Aluminum coils are highly durable due to their excellent corrosion resistance. They naturally develop an oxide layer that acts as a protective barrier against rust and degradation. This makes them ideal for use in coastal areas or locations with high humidity levels. In contrast, zinc coils, specifically galvanized steel coils, are coated with a layer of zinc to enhance their corrosion resistance. The zinc coating acts as a sacrificial layer, corroding first and protecting the underlying steel from rust. As a result, zinc coils are also highly durable and can withstand harsh conditions where the steel substrate is exposed to moisture or chemicals. Although both aluminum and zinc coils offer good durability, aluminum coils have an advantage in terms of corrosion resistance. Their natural oxide layer provides continuous protection, while zinc coils rely on the sacrificial zinc coating, which can gradually wear off over time. However, the overall durability of both types of coils depends on factors such as maintenance, usage, and the specific environment in which they are installed.

- Q:Are aluminum coils susceptible to warping or bending?

- Yes, aluminum coils are susceptible to warping or bending. Aluminum, although lightweight and highly corrosion-resistant, is a relatively soft metal compared to other materials like steel. This means that it is more prone to bending or warping under certain conditions. Factors such as excessive heat, heavy loads, or improper handling can cause aluminum coils to deform. It is important to handle and store aluminum coils carefully to prevent any damage or distortion. Additionally, proper installation techniques and maintenance practices can help minimize the risk of warping or bending.

- Q:Are aluminum coils suitable for architectural sunshades?

- Yes, aluminum coils are suitable for architectural sunshades. Aluminum is a popular material choice for sunshades due to its lightweight nature, durability, and corrosion resistance. Aluminum coils can be used to create various shapes and designs for sunshades, allowing for flexibility in architectural design. Additionally, aluminum can be easily fabricated and installed, making it a practical choice for architectural projects. Furthermore, aluminum has excellent thermal properties, allowing it to effectively reflect heat and reduce solar gain, which can help improve energy efficiency in buildings. Overall, aluminum coils are a suitable and versatile option for architectural sunshades.

- Q:Can aluminum coils be used for food storage containers?

- Yes, aluminum coils can be used for food storage containers. Aluminum is a popular choice for food storage containers due to its many beneficial properties. It is lightweight, durable, and has excellent thermal conductivity, meaning it can evenly distribute heat for efficient cooking or cooling. Additionally, aluminum is non-toxic, odorless, and resistant to corrosion, making it a safe option for storing food. It also provides an effective barrier against light, moisture, and oxygen, which helps to preserve the freshness and quality of the stored food. Overall, aluminum coils can be a reliable and practical choice for food storage containers.

- Q:Can aluminum coils be used for electronic enclosures?

- Yes, aluminum coils can be used for electronic enclosures. Aluminum is a popular choice for electronic enclosures due to its lightweight nature, excellent thermal conductivity, and corrosion resistance. Aluminum coils can be easily formed into various shapes and sizes, making them ideal for custom enclosure designs. Additionally, aluminum offers electromagnetic shielding properties, which can help protect sensitive electronic components from external interference. Overall, aluminum coils are a suitable choice for electronic enclosures, providing durability, functionality, and aesthetic appeal.

- Q:Are aluminum coils suitable for electrical transformers?

- Yes, aluminum coils are suitable for electrical transformers. They have several advantages, including lower cost, lighter weight, and better thermal conductivity compared to copper coils. Additionally, aluminum coils have been widely used in power transformers, demonstrating their suitability for this application.

- Q:if the resistivity of aluminium is 2.7×10-8 Ωm

- Let ρ be the resistivity of the aluminum cable, A the cross sectional area of the cable and l the cable's length. The resistance R of the aluminum cable is now given by: R = ρ·l / A = 2.7·10^-8·(10·10^3) / (π·r?) = 2.7·10^-8·(10·10^3) / (π·(1·10^-3)?) = 85.9 Ω I guess the tricky part is remembering: R = ρ·l / A but when you realize how intuitive this equation is you don't have to memorize it. The resistance R is proportional to the resistivity ρ, so we must have the following in our equation: R = ρ·k , where k is some value governed by the dimensions of the cable! It is logical that the resistance is also proportional to the wires length l. This is logical when you realize that the longer the wire the more obstacles the electrons will have to pass by! Now we have that: R = ρ·l·c , where c is another value governed now by the cross sectional area (only dimensional property left). If we think of the wire as a highway with cars instead of electrons we realize that there is less resistance (higher speed) when the highway has many lanes and is very broad. From this we realize that the greater the cross sectional area the smaller the resistance. R must therefore be inversely proportional to A. We now have: R = ρ·l / A I hope there are no mistakes here :P

- Q:What are the bending and forming capabilities of aluminum coils?

- Aluminum coils have excellent bending and forming capabilities due to their inherent flexibility and malleability. They can be easily bent, shaped, and formed into various complex shapes and designs without losing their structural integrity. This makes them highly versatile and suitable for a wide range of applications in industries such as construction, automotive, aerospace, and manufacturing.

- Q:Can aluminum coils be anodized in different colors?

- Aluminum coils possess the capability to undergo anodization in diverse shades. Anodization, an electrochemical procedure, forms a protective oxide coating on the aluminum surface while also enabling the introduction of various hues to the metal. By skillfully managing process factors like electrolyte type and concentration, voltage, and anodization duration, one can attain an array of colors. The color variation primarily arises from the interference and reflection of light stemming from the porous oxide layer created during anodization. Consequently, aluminum coils can be anodized in a broad spectrum of colors, encompassing shades such as black, bronze, gold, blue, red, and green, among others. The ability to anodize aluminum in diverse colors renders it an adaptable material suitable for an assortment of applications, including architectural, automotive, and decorative purposes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords