Cold Rolling Gutter Aluminum Coil 3003 3004 3105

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Cold Rolling Gutter Aluminum Coil 3003 3004 3105

Alloy: 1050, 1060, 1100, 3003, 3004, 3005, 3105, 5005, 5052, 5083, 5754

2) Temper: Various status

3) Thickness: 0.3-150mm

4) Width: 300-1950mm

5) Length: Under9500mm/ Coil

6) Weight: 2.5-5.0 tons per coil

7) Dimensions and weight can be produced according to clients' specifications.

8) Inner Diameter: 505mm, 605mm

9) Packing: Export standard, wooden pallet.

10) Delivery time: 20 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

13) Surface: Bright

14)Origin: China

2. Application of Cold Rolling Gutter Aluminum Coil 3003 3004 3105

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Cold Rolling Gutter Aluminum Coil 3003 3004 3105

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

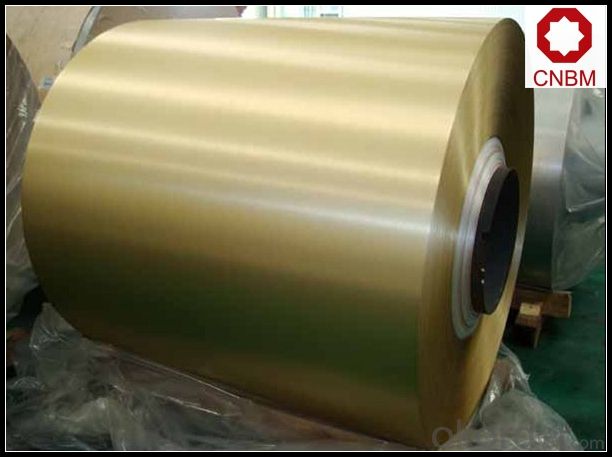

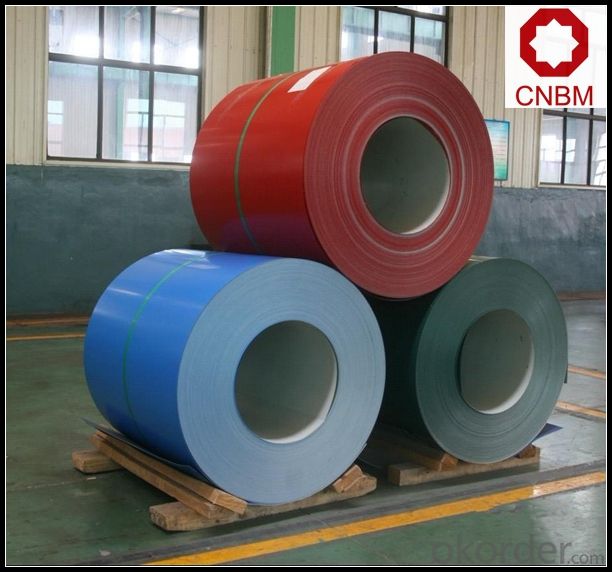

5. Image of Cold Rolling Gutter Aluminum Coil 3003 3004 3105

6. Package and shipping of Cold Rolling Gutter Aluminum Coil 3003 3004 3105

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Can aluminum coils be customized to specific requirements?

- Indeed, specific requirements can be accommodated through customization of aluminum coils. The versatility of aluminum coils allows for a broad range of specifications and applications to be met. Customization options encompass alloy selection, coil thickness, width, and length, as well as diverse surface treatments like coatings, finishes, and embossing. Furthermore, mechanical properties such as strength, flexibility, and corrosion resistance can be tailored to individual needs. To achieve desired outcomes, close collaboration with manufacturers or suppliers possessing the necessary expertise and facilities is necessary. Whether for the aerospace industry, automotive sector, construction projects, or any other usage, aluminum coils can be tailor-made to fulfill specific requirements and deliver optimal performance.

- Q:Can aluminum coils be used in automotive suspension systems?

- Yes, aluminum coils can be used in automotive suspension systems. Aluminum coils are lightweight, durable, and have excellent corrosion resistance, making them suitable for use in suspension systems. They provide better handling, improved ride quality, and enhance fuel efficiency in vehicles.

- Q:What is the composition of aluminum coils?

- Pure aluminum coils typically contain 99.5% aluminum and trace amounts of other elements. Conversely, aluminum alloys are formed by blending aluminum with metals like copper, magnesium, manganese, or zinc. These alloys are specifically engineered to bolster the strength, corrosion resistance, and other desired characteristics of the aluminum coils. The precise composition of the coils may differ based on the particular application and requirements, but in general, they contain a significant proportion of aluminum along with small quantities of other elements to yield a sturdier and more effective product.

- Q:How are aluminum coils processed for specific mechanical properties?

- Aluminum coils are processed to achieve specific mechanical properties through a series of manufacturing techniques. These techniques are aimed at altering the structure and composition of the aluminum alloy, ultimately enhancing its desired properties such as strength, hardness, ductility, and corrosion resistance. One common method used to process aluminum coils is heat treatment. This involves heating the coils to a specific temperature and then cooling them rapidly or slowly to achieve the desired properties. For instance, annealing is a heat treatment process that involves heating the coils to a high temperature and then slowly cooling them to enhance their softness and ductility. On the other hand, precipitation hardening involves a combination of solution heat treatment and aging to increase the strength and hardness of the aluminum coils. Another method used to process aluminum coils is cold working or cold rolling. This involves passing the coils through a series of rollers at room temperature to reduce their thickness and improve their mechanical properties. Cold working not only increases the strength and hardness of the coils but can also enhance their surface finish and dimensional accuracy. Furthermore, alloying elements can be added to the aluminum alloy during the casting process to achieve specific mechanical properties. For example, adding elements like copper, magnesium, or zinc can enhance the strength and corrosion resistance of the aluminum coils. In summary, aluminum coils are processed for specific mechanical properties through techniques such as heat treatment, cold working, and alloying. These techniques help modify the structure and composition of the aluminum alloy, resulting in enhanced strength, hardness, ductility, and corrosion resistance.

- Q:Can aluminum coils be used in the production of aluminum downspouts?

- Certainly, aluminum coils have the potential to be employed in the manufacturing process of aluminum downspouts. Normally, high-grade aluminum alloy is utilized to fabricate aluminum coils, which are subsequently transformed into thin sheets by means of rolling. These sheets can be conveniently cut and molded into diverse dimensions and forms, including downspouts. The lightweight, long-lasting, and corrosion-resistant characteristics of aluminum make it a favored option for downspouts. Moreover, aluminum coils can be effortlessly manipulated and shaped according to precise design prerequisites, rendering them appropriate for the production of aluminum downspouts.

- Q:and alsoHow many grams of the decay product will have formed after 8 days go by?The decay product is the new isotope created as a result of the positron decay of aluminum-24.In class my teacher didn't explain this completely but there's a question on the homework that me and even my mom (another teacher) can't find the answer to.

- so it 6000/ (2*8*24*60*60) 0.00434027778 grams have you heard of the internet an unless your mom is a chem teacher it doesnt mean much

- Q:How are aluminum coils made?

- Continuous casting and rolling is the method utilized for the production of aluminum coils. The process commences by melting aluminum ingots or scrap in a furnace. After reaching the desired temperature, the molten aluminum is transferred to a holding furnace. Subsequently, the molten aluminum is continuously cast into a solidified strip, which is then passed through a series of rolling mills. The rolling mills exert pressure on the aluminum strip, reducing its thickness while increasing its length. This procedure is repeated multiple times until the desired thickness and width are attained. Simultaneously, the aluminum strip is cooled and lubricated during the rolling process to prevent adherence to the rollers and enhance the surface finish. Once the rolling is complete, the aluminum strip is coiled to form a continuous sheet of aluminum coil. To ensure stability during transportation and storage, the coils are typically wound tightly, minimizing any air gaps. At this stage, the coils can undergo further processes such as annealing. This involves heating the coils and gradually cooling them to enhance their mechanical properties, making them more suitable for specific applications. In summary, the production of aluminum coils comprises a combination of melting, casting, rolling, and coiling procedures. The ultimate goal is to generate top-quality coils with the desired dimensions and properties.

- Q:I have the Samp;W Mamp;P 15 rifle and was wondering if I should oil the exterior of the rifle. The receiver material is 7075 T6 Aluminum and the finish is Hard Coat Black Anodized (specifications on website). Any advice or tips are welcome! Thanks!

- Aluminium does not rust. The anodized finish protects the aluminium from oxidization. So no, oiling the finish is not necessary.

- Q:How do aluminum coils contribute to energy savings in buildings?

- Aluminum coils play a vital role in HVAC systems for buildings, helping to save energy. To start, aluminum coils are highly effective at transferring heat. HVAC systems use these coils to facilitate the exchange of heat between indoor and outdoor environments. Aluminum's thermal conductivity allows for fast and efficient heat transfer, resulting in less energy needed to heat or cool a space. This means that HVAC systems equipped with aluminum coils can achieve the desired indoor temperature more efficiently, leading to energy savings. Furthermore, aluminum coils are lightweight and have excellent corrosion resistance. This property ensures the longevity and durability of the HVAC system, reducing the need for frequent replacements. By lasting longer, the energy and resources used in manufacturing new coils are saved, resulting in reduced energy consumption and environmental impact. Moreover, aluminum coils are highly recyclable. When an HVAC system reaches the end of its life cycle, the aluminum coils can be easily recycled and repurposed. Recycling aluminum requires significantly less energy compared to producing new aluminum from raw materials. By promoting recycling, energy is conserved, and greenhouse gas emissions are reduced. Additionally, aluminum's reflective properties contribute to energy savings in buildings. When used in HVAC systems, aluminum coils can reflect and deflect sunlight, reducing the amount of heat absorbed by the building. This reduces the workload on the HVAC system, resulting in lower energy consumption and increased energy efficiency. In conclusion, the use of aluminum coils in HVAC systems brings about energy savings in buildings due to their high thermal conductivity, lightweight and durable nature, recyclability, and reflective properties. By adopting aluminum coils, buildings can achieve optimal temperature control with reduced energy consumption, leading to significant energy savings and a more sustainable environment.

- Q:Can aluminum coils be used in food processing or packaging applications?

- Yes, aluminum coils can be used in food processing or packaging applications. Aluminum is a widely used material in the food industry due to its excellent properties such as corrosion resistance, light weight, and heat conductivity. It is commonly used for wrapping food, creating food containers, and in the form of coils for various food processing applications. Aluminum coils are often used for packaging perishable food items like meat, dairy products, and beverages. The coils can be easily formed into different shapes and sizes to meet specific packaging requirements. Aluminum's excellent barrier properties help protect the food from moisture, oxygen, and light, ensuring longer shelf life and maintaining food quality. In food processing, aluminum coils are utilized in various equipment such as heat exchangers, evaporators, condensers, and refrigeration systems. Aluminum's thermal conductivity allows for efficient heat transfer, making it suitable for applications that require precise temperature control. Furthermore, aluminum is non-toxic and does not react with food, making it a safe and hygienic choice for food processing and packaging. It is also recyclable, making it an environmentally friendly option. Overall, aluminum coils are widely accepted and used in food processing and packaging applications due to their versatility, durability, and suitability for maintaining the quality and safety of food products.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cold Rolling Gutter Aluminum Coil 3003 3004 3105

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords