Coir Geotextile PP/PET Nonwoven Geotextile Fabric

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Coir Geotextile PP/PET Nonwoven Geotextile Fabric

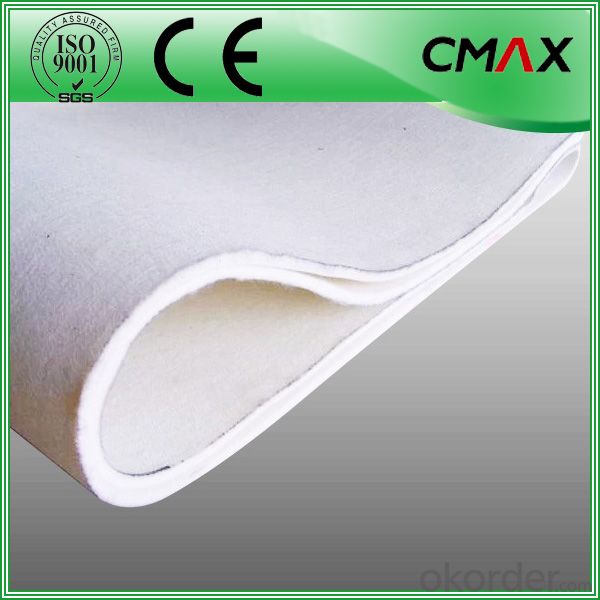

Desciriptions:

HDPE Smooth Face geomembrane are the preferred products for lining projects requiring low permeability , corrosion protection , exceptional chemical and ultraviolet resistance properties , which makes them extremely cost effective for

many applications such as waste landfill , storage reservoirs ,canals , powr plants in energy , vapor barriersand waste water treatment in the line of industry and aquaculture and agriculture projects.

Specifications:

| Weight / Mass | 100gsm - 800gsm |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Characteristics:

Easy process and high output rates

Excellent distribution of carbon black

Consistent quality and low failure rate

Excellent resistance and good waterproof ability

Good welding

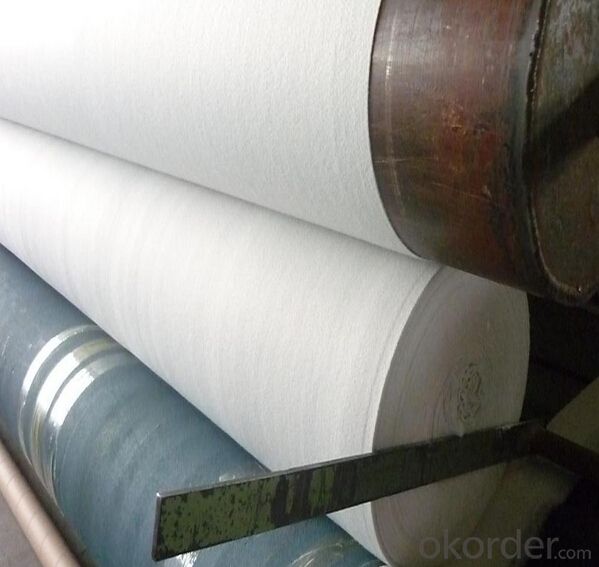

Details of our products:

Produce process:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Packing and shipping:

♦ Packing:in plastic film bag(keep away from moisture) and PP bag or as your customize.

♦ Shipping:By sea or as your customize

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q:Can geotextiles be used in retaining wall reinforcement?

- Yes, geotextiles can be used in retaining wall reinforcement. Geotextiles serve as a separation and filtration layer, preventing the mixing of soil particles and providing added stability to the wall structure. They can help distribute the load across the wall surface and improve the overall performance and longevity of the retaining wall.

- Q:Can China produce polypropylene filament geotextiles? Google knows

- Yes, I am professional production, wish smooth

- Q:What is the effect of temperature on geotextile performance?

- The effect of temperature on geotextile performance can vary depending on the specific material and application. In general, higher temperatures can lead to increased softening and deformation of geotextiles, reducing their overall strength and stability. Extreme heat can also cause geotextiles to lose their mechanical properties and become more susceptible to degradation. On the other hand, lower temperatures may cause geotextiles to become stiff and less flexible, potentially affecting their ability to conform to the underlying soil or rock. It is important to consider the temperature range in which geotextiles will be exposed when selecting and designing their use to ensure optimal performance and longevity.

- Q:How do geotextiles help with soil stabilization in foundation construction?

- Geotextiles help with soil stabilization in foundation construction by providing reinforcement and separation functions. They act as a barrier between different soil layers, preventing their intermixing and maintaining their structural integrity. Additionally, geotextiles improve the load-bearing capacity of the soil by distributing the applied loads more evenly, reducing settlement and increasing stability.

- Q:What is the latest price of geotextile?

- Per ton of national standard short geotextile 7000-8000 yuan, filament geotextile per ton - yuan.

- Q:How do geotextiles help in preventing sinkhole formation?

- Geotextiles help in preventing sinkhole formation by providing reinforcement and stabilization to the soil. They act as a barrier, preventing the migration of soil particles and reducing the potential for erosion. This reinforcement helps to maintain the integrity and strength of the soil, minimizing the risk of sinkhole formation.

- Q:What are the different geotextile filtration testing methods?

- There are several geotextile filtration testing methods used to evaluate the performance of geotextiles. Some of the commonly used methods include the gradient ratio test, the sieve analysis test, the permittivity test, the flow rate test, and the turbidity test. These tests assess the geotextile's ability to filter water, retain soil particles, and prevent clogging.

- Q:Geotextile what are the specifications of the ah?

- Geotextile is first divided into short wire geotextile and filament geotextile. Their specifications generally according to the weight to count, small equipment, geotextiles are mostly between 80g-380g, and now some mature domestic enterprises generally can do between 100g-1500g short wire and filament geotextile. How many grams of this can be customized between. It should be noted that the same specifications of the short wire geotextile price than the filament geotextile to 30% cheaper, but the technical strength index than the long geotextile cloth nearly 50%.

- Q:What are the different geotextile installation techniques for roadways?

- There are several different geotextile installation techniques for roadways, including the overlay method, the trench method, and the sandwich method. - The overlay method involves placing the geotextile directly on top of the existing soil or subgrade before adding the new road material, such as asphalt or concrete. This technique helps to separate the soil layers and prevent the mixing of materials, providing stability and reducing the risk of road failure. - The trench method involves excavating a trench along the road alignment and placing the geotextile in the trench before backfilling it with soil or aggregate. This technique is commonly used for drainage applications, as the geotextile acts as a filter to prevent fine particles from clogging the drainage system, while allowing water to flow through. - The sandwich method is a combination of the overlay and trench methods. It involves placing a layer of geotextile between the existing soil and the new road material, as well as placing another layer of geotextile on top of the new road material. This technique provides additional reinforcement and separation, enhancing the overall performance and durability of the roadway. Overall, the choice of geotextile installation technique depends on the specific requirements and conditions of the road project, such as soil type, traffic load, and drainage needs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Coir Geotextile PP/PET Nonwoven Geotextile Fabric

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords