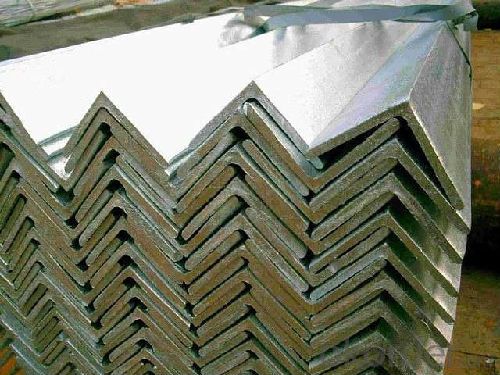

Chinese Standard Hot Rolled Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Chinese Standard Hot Rolled Angle at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Chinese Standard Hot Rolled Angle are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Chinese Standard Hot Rolled Angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Chinese Standard (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light I (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light II (H*W*T) | Weight (Kg/m) | 6M |

100*68*4.5 | 11.261 | 14.8 | 100*66*4.3 | 10.13 | 16.4 | 100*64*4 | 8.45 | 19.7 |

120*74*5.0 | 13.987 | 11.9 | 120*72*4.8 | 12.59 | 13.2 | 120*70*4.5 | 10.49 | 15.8 |

140*80*5.5 | 16.89 | 9.8 | 140*78*5.3 | 15.2 | 10.9 | 140*76*5 | 12.67 | 13.1 |

160*88*6 | 20.513 | 8.1 | 160*86*5.8 | 18.46 | 9 | 160*84*5.5 | 15.38 | 10.8 |

180*94*6.5 | 24.143 | 6.9 | 180*92*6.3 | 21.73 | 7.6 | 180*90*6 | 18.11 | 9.2 |

200*100*7 | 27.929 | 5.9 | 200*98*6.8 | 25.14 | 6.6 | 200*96*6.5 | 20.95 | 7.9 |

220*110*7.5 | 33.07 | 5 | 220*108*7.3 | 29.76 | 5.6 | 220*106*7 | 24.8 | 6.7 |

250*116*8 | 38.105 | 4.3 | 250*114*7.8 | 34.29 | 4.8 | 250*112*7.5 | 28.58 | 5.8 |

280*122*8.5 | 43.492 | 3.8 | 280*120*8.2 | 39.14 | 4.2 | 280*120*8 | 36.97 | 4.5 |

300*126*9 | 48.084 | 3.4 | 300*124*9.2 | 43.28 | 3.8 | 300*124*8.5 | 40.87 | 4 |

320*130*9.5 | 52.717 | 3.1 | 320*127*9.2 | 48.5 | 3.4 | |||

360*136*10 | 60.037 | 2.7 | 360*132*9.5 | 55.23 | 3 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q:How are steel I-beams used in residential construction?

- Steel I-beams are commonly utilized in residential construction due to their robustness and durability. They primarily serve as load-bearing structures to uphold the structure's weight. I-beams are frequently employed in constructing the principal framework, including the foundation, walls, and floors. A key advantage of employing steel I-beams is their ability to span large distances without necessitating additional support columns. This facilitates more spacious floor layouts and offers greater design flexibility. In residential construction, I-beams are commonly used to fashion vast open areas, such as living rooms or kitchens, where walls can be eliminated or reduced. Furthermore, steel I-beams are vital in supporting the weight of upper levels or floors in multi-story residences. They furnish the essential strength to bear the load and avert sagging or structural collapse. Additionally, I-beams are utilized to uphold hefty loads such as the weight of a roof or large windows, ensuring overall stability and structural integrity. Moreover, steel I-beams possess resistance against fire, decay, and pests, rendering them a dependable choice for residential construction. They also boast a commendable strength-to-weight ratio, signifying their ability to support substantial loads while being relatively lightweight. This facilitates easier and more cost-effective installation. In conclusion, steel I-beams play a pivotal role in residential construction by providing structural support, enabling open floor plans, and ensuring the safety and stability of the edifice. Their strength, durability, and versatility make them an ideal selection for contemporary homes.

- Q:Can steel I-beams be used in coastal areas?

- Indeed, coastal areas can indeed utilize steel I-beams. Steel, as a construction material, boasts durability and reliability, enabling it to endure the challenging conditions frequently encountered in coastal environments, such as strong winds, saltwater, and humidity. Nevertheless, it is crucial to carefully choose the suitable steel variant and employ protective coatings to avert corrosion. Stainless steel or galvanized steel are typically employed in coastal regions owing to their ability to resist rust and corrosion. Furthermore, consistent inspection and maintenance are imperative to guarantee the structural soundness of the steel I-beams utilized in coastal areas.

- Q:How do steel I-beams contribute to the overall aesthetics of a building?

- Not only are steel I-beams renowned for their structural strength and support, but they also make a significant contribution to the overall aesthetics of a building. These beams possess a sleek and contemporary look that can bring a touch of sophistication and elegance to any architectural design. One manner in which steel I-beams enhance a building's aesthetics is through their clean and minimalist appearance. Their slender profile and straight lines create a sense of simplicity and efficiency, which can be particularly appealing in contemporary and industrial-style buildings. Furthermore, their sleek look allows for a more open and spacious interior, as they can span long distances without requiring additional support columns. Additionally, steel I-beams can be used creatively as architectural elements in exposed structural systems. By leaving the beams visible instead of concealing them behind walls or ceilings, they become a focal point and add a unique visual interest to the space. The raw and industrial aesthetic of steel I-beams can complement various design styles, ranging from modern and minimalist to rustic and industrial. The use of steel I-beams also provides flexibility in architectural design. They can be fabricated into different shapes and sizes, enabling architects to create intricate and innovative designs. Whether utilized as load-bearing elements, decorative accents, or as part of an open floor plan concept, steel I-beams offer versatility and adaptability to architectural projects. Furthermore, steel I-beams contribute to the overall sustainability of a building. Steel is an exceptionally sustainable material as it can be recycled endlessly without losing its properties. By incorporating steel I-beams into the design, a building can demonstrate its commitment to sustainable construction practices. In conclusion, steel I-beams have a vital role in enhancing the overall aesthetics of a building by imparting a modern, minimalist, and industrial touch. Their clean lines, sleek appearance, and versatility enable the creation of innovative architectural designs, while their sustainability further enhances the appeal of the building.

- Q:What are the different types of steel I-beam connections for cantilever structures?

- There are several types of steel I-beam connections commonly used for cantilever structures, each offering unique benefits and suitability for specific applications. Some of the most commonly used connections include: 1. Welded Connection: This is the most common and straightforward method of connecting steel I-beams in cantilever structures. It involves welding the end of the beam directly to the supporting structure, providing excellent rigidity and strength. However, this method requires skilled welding professionals and may result in residual stresses. 2. Bolted Connection: In this type of connection, steel plates with holes are bolted to the ends of the I-beams and then secured to the supporting structure. Bolted connections offer ease of installation, adjustability, and the ability to disassemble and reuse the structure if needed. However, they may have some flexibility and require periodic inspection and tightening of bolts. 3. Cleat Connection: A cleat connection involves using a steel plate with holes that is welded to the I-beam's end, and this plate is then bolted to the supporting structure. This connection provides the advantages of both welding and bolting, offering high strength and adjustability. Cleat connections are commonly used for large cantilever structures due to their robustness and versatility. 4. Moment Connection: This type of connection is designed to transfer bending moments between the I-beam and the supporting structure. Moment connections often involve welding stiffeners or plates to the beam's flanges and web, creating a rigid joint. These connections are ideal for structures subjected to large loads and moments, such as bridges or heavy industrial applications. 5. Shear Connection: Shear connections primarily transfer the vertical loads between the I-beam and the supporting structure. These connections typically involve welding or bolting steel plates to the beam's flanges and webs, providing excellent load-bearing capacity. Shear connections are commonly used in cantilever structures where heavy vertical loads need to be supported. It is important to consider the specific requirements and load conditions of the cantilever structure when selecting the appropriate type of steel I-beam connection. Consulting with a structural engineer or experienced professional is recommended to ensure the optimal connection method is chosen for your specific application.

- Q:What does "I-beam 125A" mean?

- The specifications are expressed in terms of waist height (H) * leg width (b) * waist thickness (d), such as "work 160*88*6", which means that the waist height is 160 mm, the width of the leg is 88 mm, and the waist thickness is 6 mm. The specifications of I-beam can also be expressed by type. The number of centimeters is indicated by the model, such as "work 16", which means waist height is 16cm.

- Q:Span seven meters of suspended beam, can I put a beam inside the beam with pouring, increase the intensity?

- Weld the I-beam stage to the 2 side of the beam. Do not cut the beam into the i-beam!Just don't cut the beam. Cut the I-beam into 2 sections, one at the left of the beam, and the other on the right side of the beam.

- Q:What are the tensile, shear, Xu Yun, and Xu Yun deflections of 20a I-beam?

- Standard design of steel structure is the total probability method, the design strength of Q235 steel plate is 215N/mm2 tensile shear stress, the load is 125N/mm2, the situation is not clear when don't use this!

- Q:Do steel I-beams have any aesthetic applications in architecture?

- Yes, steel I-beams can have aesthetic applications in architecture. While they are primarily used for structural purposes due to their strength and load-bearing capabilities, they can also be incorporated into the design of a building to create a visually appealing and modern aesthetic. Steel I-beams can be exposed, allowing their sleek and industrial appearance to become a feature of the architectural design. This can be particularly effective in contemporary and industrial style buildings where the raw and rugged aesthetic of steel is desired. Additionally, the use of steel I-beams can create open and expansive interior spaces, allowing for large, uninterrupted spans and creating a sense of openness and modernity. Overall, steel I-beams can be used creatively in architecture to not only fulfill structural requirements but also add aesthetic value to a building's design.

- Q:What angles, angles and channels are used in general? Please try to be specific

- In the construction, steel can be used for the main stress parts, such as column and beam; steel stairs, generally used for road; angle plays a secondary role such as support, knee brace etc.

- Q:Are there any insulation requirements for steel I-beams?

- Yes, there are insulation requirements for steel I-beams. Steel is a highly conductive material, meaning it can easily transfer heat and cold. Therefore, when steel I-beams are used in building construction, it is important to insulate them to prevent heat loss or gain and enhance energy efficiency. The specific insulation requirements for steel I-beams may vary depending on factors such as the type of building, its location, and local building codes. However, there are general guidelines and standards that can be followed. One common method of insulating steel I-beams is by using insulation materials such as mineral wool, spray foam, or rigid foam board. These materials are typically applied around the steel beams to create a thermal barrier, preventing the transfer of heat or cold. The thickness and type of insulation required will depend on several factors, including the desired R-value (a measure of insulation effectiveness) and the specific building requirements. It is advisable to consult local building codes and professionals such as architects or engineers to determine the appropriate insulation requirements for steel I-beams in a specific project. Insulating steel I-beams not only helps to regulate temperature within a building but also reduces energy consumption, improves comfort levels, and can contribute to achieving sustainable building certifications like LEED (Leadership in Energy and Environmental Design). In summary, insulation requirements for steel I-beams exist to ensure energy efficiency and thermal comfort in buildings. Following local building codes and consulting with professionals will help determine the appropriate insulation materials and techniques to use for steel I-beams in a construction project.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Chinese Standard Hot Rolled Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords