Ceramic Fiber textiles with Excellent Tensile Strength 2015

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

New 2015 Ceramic Fiber Textile with Excellent Tensile Strength

Product Description:

Product Applications:

• Industrial furnace, heating devices, high temperature pipe wall linings;

• High temperature boilers, steam turbine and Nuclear power thermal insulation;

• Chemical industrial high-temperature reaction equipment and heating equipment wall linings;

• High building fireproof and thermal insulation;

• Furnace door and roof thermal insulation;

• High temperature filter materials

Product Specifications:

Place of Origin: | China (Mainland) | Shape: | Plate | Material: | Ceramic Fiber |

SiO₂ Content (%): | 55Max | Al₂O₃ Content (%): | 35Min | MgO Content (%): | 0 |

CaO Content (%): | 0 | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | 0 |

SiC Content (%): | 0 | Model Number: | As per request | Brand Name: | |

Color: | white | Thickness: | ~30mm | Characteristics: | Lightweight |

Product Packaging:

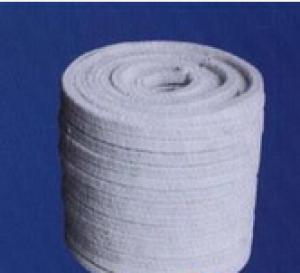

Packaging Detail: | One roll in a box (25kg) |

Delivery Detail: | ~25 days after receiving deposit |

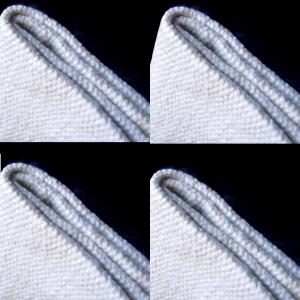

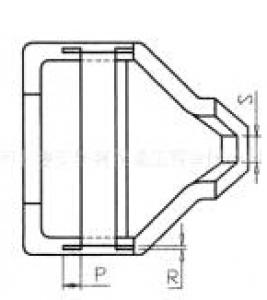

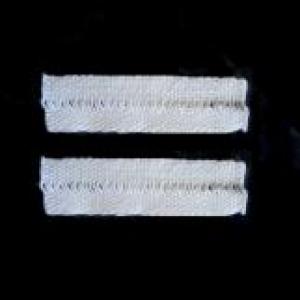

Product Images:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What other products does OKorder offer?

A3: We offer a full range of refractory bricks, mortar, cement, ceramic fiber products, and more.

Q4: Where are Ceramic Fiber products used?

A4: Ceramic fiber products have many advantages, including: high temperature stability, lightweight, superior insulation, and ease of application. Fiber products are available in a variety of product forms to solve a range of thermal management application problems across various industries. The main industrial market segments that use ceramic fiber and soluble fiber products are the aluminum, iron, steel, heat treatment, power, incineration, boilers, and glass industries.

Q5: What kind of Ceramic Fiber should I use?

A5: When selecting the fiber type for a particular application, it is important to consider all factors. If the fiber/fabric will not have to support a load at temperature, the lower-cost industrial grade fibers may be appropriate. However, if the fiber will be load bearing at temperature as in ceramic matrix composites, then one of the composite grade fibers would be a better choice. Of course there may be other factors, such as corrosion, chemical resistance, or atmospheric conditions that may require trade-off in the selection process.

Q6: What`s the lead time for my order?

A6: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q7: Can you offer Door-to-Door delivery?

A7: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q8: What is the minimum quantity?

A8: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

- Q:The difference between ceramic fiber cloth and ceramic fiber paper

- Ceramic fiber paper and ceramic fiber cloth are refractory insulation materials, which can be used for insulation and heat preservation

- Q:What are the uses of ceramic fiber blankets?

- The ceramic fiber blanket has a strong resistance to wind erosion, and can be directly contacted with flame and high-speed airflow. Because of its excellent fire resistance, high temperature stability, high thermal shock resistance, low heat capacity and high temperature conditions, high compressive strength.

- Q:What are the differences between digital textile printing ink and printing ink?

- Under the new economic environment, the textile industry will enter a short process, digital production mode. Nowadays, more and more printing and dyeing mills use wide format inkjet printing to produce.

- Q:Does the component of textiles contain 70% acrylic? Does it hurt the body?

- Organic glass comes from English Organic Glass. In recent years, in some areas the sheet is made of transparent plastic all are called organic glass, actually this is wrong, it refers to pure acrylic polymethylmethacrylate (PMMA) and the PMMA sheet material, called acrylic plate.

- Q:What is the function of (ceramic) ceramic powder?

- Opaque porcelain: cover the color of the base crown and increase the retentionNeck edge porcelain: also called neck porcelain, darker color, showing neck colorBody porcelain: also called dentin porcelain, the main porcelain powder, used to obtain the natural beauty of dentinEnamel porcelain: also called cut end porcelain, used for cutting ends, translucencyTransparent porcelain: reflects the natural and transparent shape of teethGlaze powder: colorless and transparent, simulating the luster of enamelThere are modified porcelain, dyed porcelain, gums, porcelain and so on, can show different colors and special restoration needs.

- Q:Is aluminum silicate fiber completely insulated from heat transfer?

- Fire-resistant insulation layer is used to make ceramic fiber module insulation, thermal insulation thickness of four hundred mm, the ceramic fiber blanket double extrusion, ceramic fiber module in parallel sorting, the trolley furnace wall temperature to plate temperature rise of forty-five degrees, which is almost a best isolation effect.

- Q:Which is better, ceramic fiber or spray velvet?

- Different applications of two kinds of ceramic fiber cotton:In 1, production of HLGX ceramic fiber module: rejection due to thick and long silk fiber is better than spraying silk carpet, in the block made of the folding process, blowing fiber blankets easily broken and torn, and thrown silk fiber blanket can be folded very closely and not easy to damage, the quality will directly affect the block lining quality;The vertical layer 2, large boiler insulation blanket shop carpet fiber application: rejection due to long and thick, has better tensile resistance, more durable, so the rejection is better than spray carpet carpet;3, application of ceramic fiber textile, silk fiber thick and long and has good spinnability, the ceramic fiber thrown silk became the production of ceramic fiber textiles (cloth, tape, rope, pipe and other special materials);

- Q:Can ceramic fibers be spun?

- Ceramic fiber itself is relatively brittle, silk is relatively short, spinnability, but after adding viscose (differential polyester glass fiber, even pulp) as the heart can be spun,

- Q:What's the temperature of the high temperature ceramic fiber cloth and ceramic drill cloth?

- The ceramic fiber cloth is only one kind of one thousand degree temperature resistance. It is reinforced cloth for steel wire.

- Q:Is everybody's ceramic fiber cloth poisonous?

- Ceramic fiber products with excellent heat resistance, with heat-resistant alloy reinforced aluminum silicate dimensional textiles, continuous use temperature of 1000 degrees, excellent acid resistance and oil, water vapor corrosion capacity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber textiles with Excellent Tensile Strength 2015

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords