Calcined Alumina Powder for Refractory Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Calcined Alumina Powder for Refractory Use

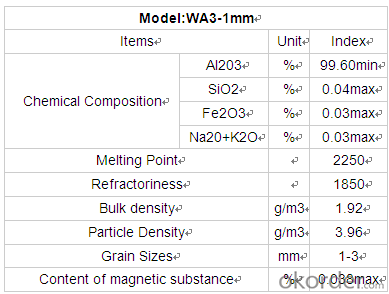

Specification:

High purity AL2O3 Aluminum Oxide/ Aluminum powder

Manufacturer

Superfine

Application:

1. aluminium oxide for aluminium smelting, glass, ceramic industry etc.

2. aluminium oxide for refractory, coating, abrasive applications.

3. aluminium oxide for electric basal plate, desiccating agent, chemical and pharmacy industry, etc.

aluminum oxide property:

The product is white powder,uniform of particle size,easy to dispersion,stable of chemical performance,moderate in high temperature shrinkage and excellent sintering properties.

The product is the basic raw material in the production of heat-resisting product,abrasion-resisting products and decay resistance products such as for producing the high alumina refractories, high-strength ceramics, automobile spark plugs and high-grade abrasive materials.

aluminum oxide property:

Soluble in water white solid. Odourless. Tasteless. Qualitative very hard. Easy absorption of moisture and not ChaoXie. Both sexes oxide, soluble in inorganic acid and alkaline solution, almost insoluble in water and the polar organic solvents. The relative density (d204) 4.0. Melting point about 2000 °C.

The physical and chemical analysis:

Main standard:

Alumina(industry grade) made by slkali-lime sintered,It is white powdered crystal with low assay of Ti, Mn, Zn, Cu, V, Zr, Cr, Li, Pb, B, P, etc.It is used in the production of fused salt eletrorefining aluminium, corundum eramics, refractories and other alumina chemical products.

Product Pictures:

If you’ve any enquiry please don’t hesitate to contact us!

- Q:How do refractory materials apply into pyrophyllite?

- Generally speaking, shaped refractory materials require of some powdery materials like spray grouts and iron trough in addition to pyrophyllite brick made of a mixture of pyrophyllite aggregate and powers.

- Q:What is the role of adding chromium oxide green in unshaped refractory materials

- Generally, less is added in corundum or corundum spinel refractory material, but it can significantly improve the material performance such as high temperature strength, erosion resistance, thermal and shock stability, etc.

- Q:What types does soft fire prevention materials have?

- Types of fire resistant species. Mainly listed as follows: finishing fire retardant paint, component fire retardant coating, fire-resistant coating for steel structure and othe kinds of fire retardant coating. Flame retardant plastics and its products, textiles, building materials, flame retardant fabric and exterior wall thermal insulation system products, floor materials, such as various types of fire prevention materials;Fire prevention board, fire doors, fire prevention, fire shutter, fire glass window frame, elevator doors, ventilation pipes, fire blocking material, fire smoke exhaust fan and other kinds of artifacts (resistance) fire prevention. Indicators of judging fire mainly include: difficult to fire, ignition, smoke toxicity, smoke density, heat release and flue gas; fireproof performance, combustion performance and combustion heat value, fire resistance, high temperature resistance, fire rating, etc. And some specific parameter is needed to use professional testing instrument to judge, but to the inorganic lab for understanding, fire prevention level test result accuracy.

- Q:Can anyone tell me what is the material of which the mould for refractory is made?

- I can make the mould and give you a discount. If necessary, you can contact me at 261240643 (qq).

- Q:How to make fire resistant materials for building stoves

- Why Qianjun game protected mode can attack the foreign baby call

- Q:As for fireproofing material rock wool and glass wool, which one is better?

- As for fireproofing effect, the effect of rock wool is certainly better than glass wool , the highest temperature of rock wool is 1100 ℃, but the temperature of glass wool is only 600 ℃. In addition, if it's used in the external walls, then,unit weight of the glass wool is limited,and high unit weight can only be 60-90, but unit weight of rock wool can reach over 140, now external wall can't use glass wool, and only rock wool is A class fireproofing material. glass wool has lower thermal conductivity, rock wool has longer fiber length,as for the price, tons price of glass wool is more expensive than rock wool, but if it's acculated by square, square price of glass wool is cheaper than rock wool.

- Q:I know which material is the fire resistance rolling shutter door

- the materials of fire resistance rolling shutter door are: the inner of fire resistance rolling shutter door is generally filled with aluminum silicate fiber cotton. fire resistance rolling shutter door is divided into AAA inorganic fireproof rolling shutter door and steel fire resistance rolling shutter door. the fireproof?performance of inorganic fireproof rolling shutter door is better, but steel fire resistance rolling shutter door has a certain wind load resistance, which can be installed outdoors.

- Q:How many refractories are there for boiler above 1200 ℃?

- In addition to refractory brick, refractories include refractory concrete (refractory cement+aggregate), fire-resistant insulating layer (refractory cement+vermiculite powder or refractory cement + diatomaceous earth) and the like. Refractories often used are azs brick, corundum brick, direct-bonded?magnesia-chrome?bricks, carborundum brick, silicon nitride bonded silicon carbide brick, nitride, silicide, sulfide, boride, carbide and other nonoxide refractory materials, calcium oxide, chromium hemitrioxide, aluminium oxide, beryllia and other refractories. Thermal insulation refractory materials often used are diatomite product, asbestos product, insulation?board,etc. Unshaped refractories often used are repairing?mass, ramming?mass, castable refractory, plastic refractory, refractory mortar, refractory gunning mix, sling refractory, refractory coating, lightweight refractory?castables, stemming, etc.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Calcined Alumina Powder for Refractory Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords