Butterfly Valve Stainless Steel Threaded Directional with Good Quality Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

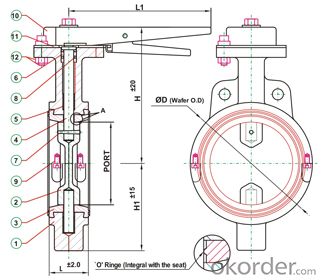

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q:What are the valve types H, F, and Y? What are the meanings of these 3 letters?

- Please refer to "JB/T308-2004 valve model preparation method"Sealing surface material codeH Cr13 stainless steelF fluoroplasticY cemented carbide

- Q:What do letters represent in the QF-2 and PX-32 valve models?

- This is the material code, specific check: valve code. Just OK

- Q:What is a heavy body valve?

- You should be asking what a heavy-duty valve is.This is only in the ordinary gate valve and cut-off valve on the distinction. Nowadays, ordinary gate valves and cut-off valves are divided into heavy-duty ones. Medium and light three kinds ~!

- Q:Is there any problem with connecting the geothermal valves with other geothermal pipes?

- Yes, as long as it's all PPR's.Material is the same, the fuse will not cause shrinkage when you can use

- Q:What's the caliber of the valve 1/4?

- 1 inches is equal to 25.4mm, 1/4 how big, count it yourself.

- Q:What is the choice of pneumatic valve or electric valve for ultrafiltration inlet control valve?

- The difference between the three is as follows: pneumatic valve]: driven by compressed air valve. Operation principle: the pneumatic control valve is composed of actuating mechanism and regulating mechanism. The actuating mechanism is a thrust component of the regulating valve, which generates the corresponding thrust according to the pressure of the control signal, and drives the regulating mechanism to move. The valve body is the regulating component of the pneumatic control valve. It contacts the regulating medium directly and regulates the flow of the fluid. [hydraulic valve]: the use of oil and other liquid pressure driven valve. The working principle of the hydraulic valve control valve pressure control valve flow control valve control valve control valve to control the direction of hydraulic system oil flow direction or liquid flow through the valve two, the working principle of the valve core and the valve body and valve off valve two-way hydraulic lock check valve to make oil movement off or on, changing the direction of the oil flow, so as to realize the hydraulic actuator and its driving mechanism of starting and stopping or changing the direction of movement. [electric valve]: with electric actuators to control the valve, so as to achieve the valve opening and closing. The utility model can be divided into two parts, the upper part of which is an electric executor, and the lower half of which is a valve. Also called air conditioning valve. The electric valve is usually connected by the electric actuator and the valve, and it becomes an electric valve after installation and debugging. The electric valve uses the electric energy as the power to switch on the electric actuator to drive the valve and realize the valve switching and regulating action. So as to achieve the purpose of switching or regulating the pipeline medium.

- Q:How to open the gas valve with drawings

- It's different from place to place. Some are pulled out half, and some are pulled out. Third: in the following there is a black disk like thing, commonly known as the gas sound core. This one is the same as the second one, half or all

- Q:What valves are needed on the construction site?

- Order valve flow1, customers have special requirements for products, must provide the following instructions in the contract: a) b) the length of the structure connection form C) nominal diameter, full size, shrinkage, pipe size d) using medium and temperature and pressure range E) test, inspection standards and other requirements.2, the factory can be configured according to customer specific requirements of various driving devices.3. If the customer provides the type and model of the valve to be determined, the customer shall correctly explain the meaning and requirements of the model and sign the contract on the condition that both the supply and demand sides agree.4, futures, order customers, please call the letter in detail to tell you the required valve model, specifications, quantity and delivery time, location, factory information, billing information, delivery address. And in accordance with the total amount of 20% of the predetermined amount or full amount of money, timely import our factory account, and the rest of the payment before shipment, import, in order to arrange delivery in time.

- Q:In the decoration, I do not know where to get the valve, what kind of products should be bought?It is hard to fit the valve in the water inlet of the house. If not, can you? Will it have any effect on future use?

- There are two types of valves used for decoration:1. inlet pipe valve: general use of ball valve, can adjust the size of water.2. triangle valve for soft tube: used for water tank, basin, bathtub, toilet, water heater hose and water connection.The water valve is best fitted to facilitate overall or partial maintenance.

- Q:What's the difference between a valve and a valve?

- The correct unit should be called "group". A set of threaded valves include valves, live connections, and short tubes. A set of flanged valves consist of a pair of flanges (including bolts, gaskets, rubber pads), and short tubes".

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Butterfly Valve Stainless Steel Threaded Directional with Good Quality Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords