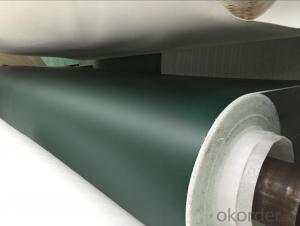

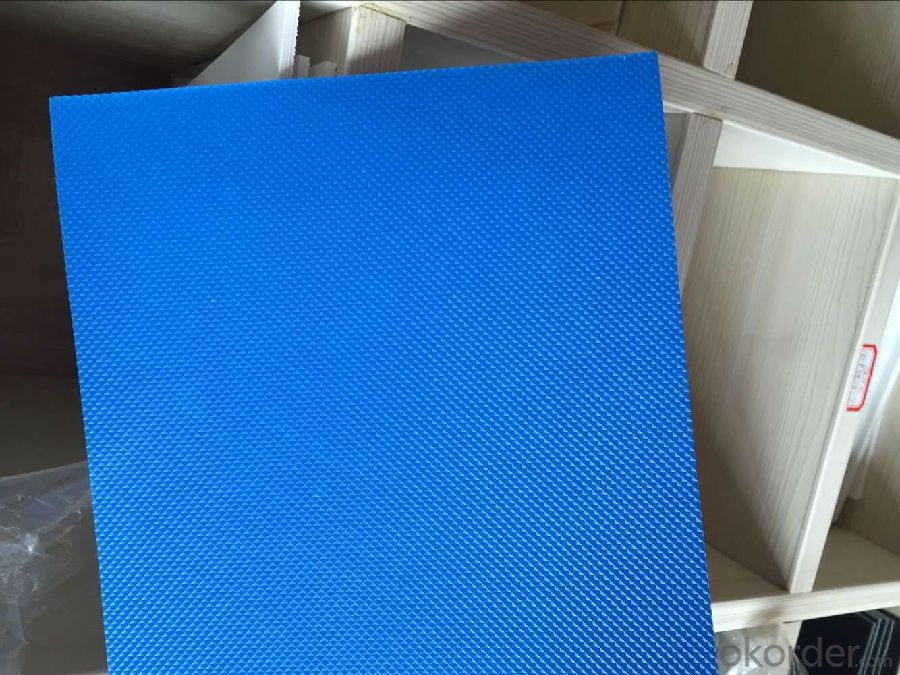

Blue/Green/White Diamond Surface PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Blue/Green/White Diamond Surface PVC Conveyor Belt

PVC/PU Conveyor Belt

Surface pattern is diamond. Three layers of nature fabric. Three layers of pvc glue.

The maximun width: 2000mm

Temperature:-10℃~+80℃

Other detailed information please contact!

Colors: red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness: PVC (1~7mm) PU (0.8~4mm)

Appearance: flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages: PVC: economical and practical, technology is mature.

PU: applicable to the food industry, abrasion resistant and corrosion.

Subsequent machining technology: it can add baffle, skirt, sponge, guide bar.

ADVANTAGES:

Low operating noise and costs, reduced maintenance, excellent durability.

Largely impervious to oils, greases and many chemicals.

Special types give excellent grip on inclination.

Abrasion resistant - rugged, high strength - low stretch characteristic.

Light and thin, better strength / weight ratio - energy saving.

Superb tracking over great length - longitudinally flexible and laterally stiff.

Please contact us freely if you need any conveyor belt.

- Q:Can olive nets be used to protect against deer or other wildlife?

- Yes, olive nets can be used to protect against deer or other wildlife. Olive nets are known for their durability and effectiveness in preventing animals from accessing crops, including deer and other wildlife. They can be easily installed and provide a physical barrier, keeping the animals away from the protected area.

- Q:Are there any environmental concerns related to the use of olive nets?

- Yes, there are environmental concerns related to the use of olive nets. One concern is the potential harm to birds and other wildlife that may become entangled in the nets. Additionally, the use of nets can damage or disrupt the natural habitat and ecosystem, affecting the biodiversity of the area. The disposal of these nets also poses a problem as they are often made of non-biodegradable materials, contributing to plastic waste.

- Q:How do olive nets affect pollination?

- Olive nets can potentially affect pollination by acting as a physical barrier that restricts the movement of pollinators such as bees and other insects. These nets are used to protect olive trees from pests and birds, but they can also unintentionally prevent pollinators from accessing the flowers, hindering the process of pollination. As a result, the use of olive nets may reduce the overall pollination success of olive trees, ultimately impacting their fruit production.

- Q:Advantages and disadvantages of plastics

- Plastics have better corrosion resistance to ordinary acids, alkalis, salts and greases than metals and some inorganic materials. Especially suitable for chemical plants such as doors and windows, floors, walls and so on.

- Q:Do olive nets affect the tree's growth or health?

- Yes, olive nets can affect the tree's growth and health. While nets are primarily used to protect the olives from birds and other pests, they can also have some negative effects. Olive nets can limit sunlight and air circulation around the tree, potentially leading to reduced photosynthesis, increased humidity, and the spread of diseases. Additionally, if not properly installed or maintained, nets can cause damage to branches or trunks, further impacting the tree's health. Therefore, it is important to carefully manage the use of olive nets to minimize any negative effects on the tree's growth and overall health.

- Q:Plastic molding is what to do, how the process?

- The plastic molding is various forms (such as powder, granules, solution and dispersion) of plastic products or parts required for the shape of. As many as 30 kinds of molding method.

- Q:Can olive nets be used on olive trees in pots or containers?

- Yes, olive nets can be used on olive trees in pots or containers. Olive nets are typically used to protect the olives from birds and other pests, regardless of whether the tree is planted in the ground or in a container.

- Q:How do olive nets affect the overall oil content of the olives?

- Olive nets do not directly affect the overall oil content of olives. Their main purpose is to catch the olives as they fall from the tree during harvesting, preventing damage and loss. The oil content of olives is determined by various factors such as olive variety, climate, soil conditions, and maturity at harvest.

- Q:Can olive nets be used to protect against diseases?

- No, olive nets are primarily used to prevent pests and birds from damaging olive crops, but they do not provide protection against diseases.

- Q:Can olive nets be used in hilly or uneven terrains?

- Yes, olive nets can be used in hilly or uneven terrains. Their flexible and adjustable design allows them to adapt to the contours of the land, ensuring effective coverage and protection for olive trees.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Blue/Green/White Diamond Surface PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords