Black Scaffolding Tube 48.3*3.6 Q235 Steel Standard EN39/BS1139 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

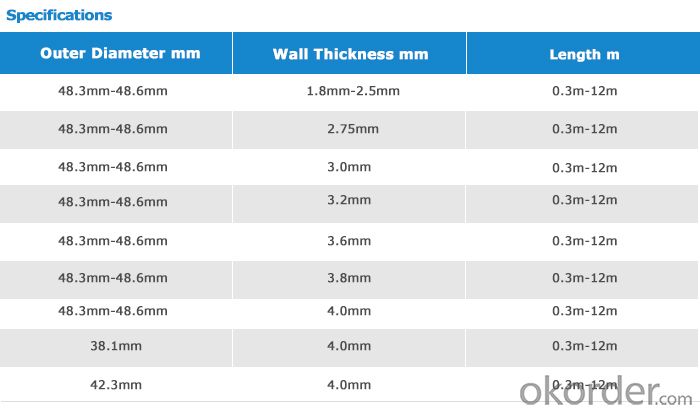

Quick Details of Black Scaffolding Tube 48.3*3.6mm Q235 Steel EN39/BS1139

Material :Q235 (Carbon 235 Steel)

Size : 48.3*3.6mm

Surface treatment :Black/Painted/Galvanized

Color : black

Standard:EN39/BS1139

Futures of Black Scaffolding Tube 48.3*3.6mm Q235 Steel EN39/BS1139

Scaffolding tubes performance various functions in building & construction applications.

Especially recommended for high-floor construction & decoration projects with potential safety hazard, but requiring a convenient & safe decoration & construction operation with safeguard & perimeter safety nets.

Low cost & high load bearing capacity

Easy installation & operation& transport

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q:I plan on playing tennis and doing track and field at school... Im getting the piercing this month and it won't be healed in time to take it out. How can I conceal it or possibly even help it heal faster??

- Well an industrial piercing isn't exactly going to get in your way, just put your hair up in a pony tail so your hair doesn't get snagged on it. I wouldn't suggest trying to cover it with anything though, you'll be putting the piercing at risk of infection from trapping bacteria, especially if you're going to end up sweating.

- Q:What are the components of a mobile scaffolding

- The main parts of the door type scaffolding are the basic structure of the door frame, the cross support, the connecting rod, the hanging button type foot board or the horizontal frame, the lock arm, etc.

- Q:I want to get a scaffolding piercing, but i just wanna know some information.. past experiences etc. So far i have two lobe piercings on both ears and the pain wasn't too bad, but i've never had a piercing on the upper ear. How much will it cost? (I live in the UK) Just some information i guess (: thanks

- I have two lobe piercings on both ears, two cartilage piercings and an industrial that i got five months ago. I was expecting my industrial to be very painful but it wasn't that bad (i have a high pain tolerance though) its a bearable pain. Like all other piercings the healing process is the worst part and still when i bump it (like when im doing my hair) it hurts like a B****! lol. And don't play with it alot when you first get it, it causes scar tissue bumps. Use H20cean spray or you can do 1/4 tsp of sea salt and 1 cup of water to help heal it. The healing time is long, 4 months to a year. I paid $65 dollars in the us idk how much that is UK. It was definitely worth it though! Go for it :)

- Q:Calculation method of complete scaffold

- The most distant light is closer to us than the nearest darkness:Distance is usually just a myth

- Q:Cells from an animal's muscles are processed with chemicals and they grow. The cells are transferred to a metal scaffold and are stimulated physically. In a few months, you have a big block of meat which can be ground and cooked. What do you have to add? Does this innovation mean the price of meat will become a very minor expense?

- Sounds weird. When eaten I wonder how this experiment would affect the human body. It just might turn normal people into Liberals. If that's the case then I don't want anything to do with it.

- Q:I have to write a 1 page commentary on a geographical issue for school, and, I've never done that before.Could someone please tell me or link me to a very simple 'writing commentary' scaffold for beginners?Please?Thankyou :)

- To know about College and university! log on to alumne /

- Q:Should the WWE put John Cena in a triple threat thumbtack scaffold cage of death with New Jack & Necro Butcher?

- i sharted. PS: please purchase my new toilet hawaii chair

- Q:At 16 I took my bros 16 gauge piercing needle and pierced my left cartilage and it didn't hurt at all.... and I have a tattoo as well and I laughed through it. So pain isn't huge when it's a small amount.

- once you get it pierced do no longer stressful up bc its going to harm like 10 situations extra. stay comfortable and actual do now not sleep on it in view which you will awaken day after today with a swollen ear and in discomfort. sparkling it thrice an afternoon for 12 weeks. And basically a reminder cartilage piercings do take a together as to heal. Mine took a pair of 365 days in a a million/2 to absolutely heal. meaning the place i became into waiting to sleep on it and not harm.the place i became into waiting to pass it around without it getting contaminated minutes later. you may haven't any problem with it as long as you're looking after it =) And from a a million to 10 i say its between a 7 and eight once you get it pierced bc it does throb after.

- Q:How to solve the problem of scaffold pipe repair

- Easy to move, straightening, derusting, ash removal, painting can be completed on the same machine at the same time, labor saving, labor-saving, easy to operate, can be adjusted 48mm Phi - Phi 51mm of all types of steel pipe

- Q:Bracket cast-in-place beam bracket must use bowl buckle scaffold, can not use fastener type scaffolding, there is no mandatory requirements, or specification file requirements!

- 3.1.2, clearly defined the quality requirements of fasteners, so you can use fasteners

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Black Scaffolding Tube 48.3*3.6 Q235 Steel Standard EN39/BS1139 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords