Automatic Auger Filling Machine for powder and granular

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of the Automatic Auger Filling Machine

This Machine is a complete, economical solution to your filling production line requirements.can measuring and filling powder and granular. It consists of the Filling Head, an independent motorized chain conveyor mounted on a sturdy, stable frame base, and all necessary accessories to reliably move and position containers for filling, dispense the required amount of product, then quickly move the filled containers away to other equipment in your line (e.g., cappers, labelers, etc.).it fits more to the fluidic or low-fluidity materials, like milk powder, albumen powder, pharmaceuticals, condiment, solid drink, white sugar, dextrose, coffee, agriculture pesticide, granular additive, and so on.

2. Features

- Lathing auger screw to guarantee the precise filling accuracy

- PLC control and touch screen display

- Servo motor drives screw to guarantee stable performance

- Quick disconnecting hopper could be washed easily without tools

- Can be setting to semi-auto filling by pedal switch or auto filling

- Full stainless steel 304 material

- weight feedback and proportion track to materials, which overcomes difficulties of filling weight changes due to materials’ density change.

- Save 20 sets of formula inside the machine for later use

- Replacing the auger parts, different products ranging from fine powder to granule and different weight can be packed

- Multi language interface

3. Technical parameters

First type-Liner type

| Model | TP-PF-A21 | TP-PF-A22 |

| Control system | PLC & Touch Screen | PLC & Touch Screen |

| Hopper | Quick disconnecting hopper 25L | Quick disconnecting hopper 50L |

| Packing Weight | 10 - 5000g | 10 - 5000g |

| Dosing mode | Directly dosing by auger | Directly dosing by auger |

| Paching accuracy | ≤500g, ≤±1%; >500g,≤±0.5% | ≤500g, ≤±1%; >500g,≤±0.5% |

| Filling speed | 15 - 40 times per minute | 15 - 50 times per minute |

| Air supply | 6 kg/cm² 0.05m³/minute | 6 kg/cm² 0.05m³/minute |

| Power supply | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Total power | 1.6 KW | 1.6 KW |

| Total weight | 300 kg | 300kg |

| Overall Dimensions | 2000*970*2030mm | 2000*970*2300mm |

Second type- Rotary type

| Model | TP-PF-A301 | TP-PF-A302 |

| Hopper volume | 25L | 50L |

| Container size | φ20-100mm; H15-150mm | φ30-160mm; H50-260mm |

| Control system | PLC & Touch screen | PLC & Touch screen |

| Packing weight | 1 - 500g | 10 - 5000g |

| Packing accuracy | ≤100g, ≤±2%; 100-500g,≤±1% | ≤500g, ≤±1%; >500g,≤±0.5% |

| Filling speed | 20-50 bottles per minute | 20-40 bottles per minute |

| Power supply | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Total power | 1.2 KW | 2.3KW |

| Air supply | 6kg/cm² 0.05m³/minute | 6kg/cm² 0.05m³/minute |

| Total weight | 160kg | 260kg |

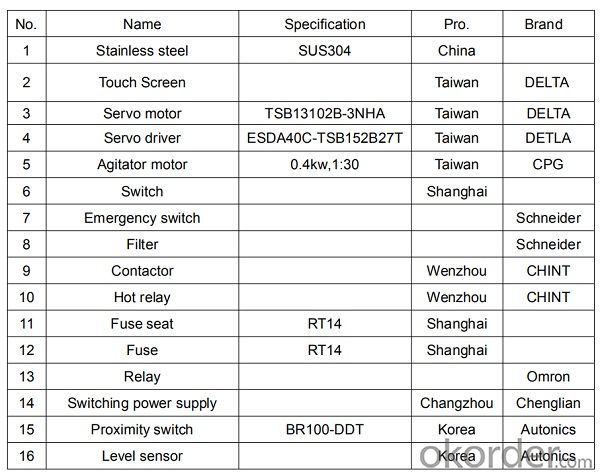

4. Configuration list

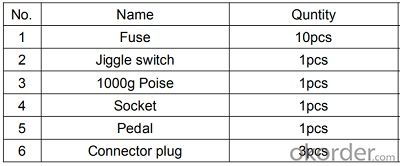

Accessories

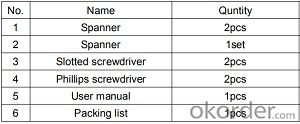

Accessories tools

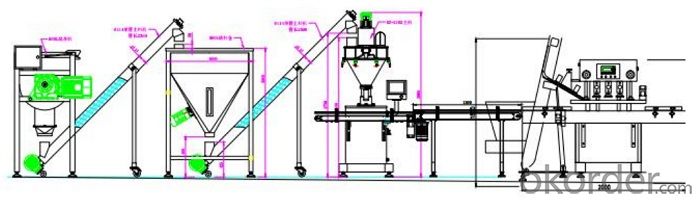

5. Image of fonction

6. Remark

- Delivery Period: 25 days after receipt of down payment

- Payment Terms: 30%T/T as deposit + 70%T/T balance payment before delivery.

- Guarantee Period: 12 months

- Package: seaworthy plywood carton

- Q:How is it based on the characteristics of various handling systems

- How are you The various elements of the moving material should be considered in the choice of handling equipment including the moving and method used

- Q:What is the difference between the requirements check function and the anti-check material list

- The first is the relevance of the material, and any material is always present because of a need; There is no need for materials without requirements. The second is the liquidity of the material, since there is demand, the material always flows from the supply side. The correlation of materials determines the liquidity of the material. Finally, the material is valuable, on the one hand it occupies the capital, in order to accelerate the turnover of funds, the material flow should be accelerated. , on the other hand, in the process of material form and change of flow, with innovation competition () is not only reduce the price competition, improve the technology content and added value of material, with minimal cost, the shortest cycle, best service, to provide customers the best value and bring their own corresponding profits. This is where the value added chain means. Three properties interact and influence each other. Understanding the management characteristics of materials can help to understand the characteristics of material requirements management. Material requirement types in terms of manufacturing, due to the material requirements according to different sources, MRP Ⅱ system divides into the material "independent requirements (independent demand)" and "related requirements (dependent demand)" two kinds big. This is the first of the material requirements planning (MRP) founders, Dr. Joseph a. rlicky, an expert at IBM, in 1965.

- Q:Ask for material handling robot design report

- Now to * * * * provided free of charge is the prototype of the robot from the plane, surface, on the steps, or wheels powered by power with the feet, you don't have to like Honda robot behind bear power battery; Of tsinghua university, Dr Robot professional to work in Beijing jiaotong university after manufacture and displayed on the (shenzhen robot also towing power supply cable, and environmental protection, and innovation, also put forward the new method of raider buggies competition; * * * is a display of patriotism, defense, military and science popularization of education. As to surpass foreign flight simulator XunLianCang, can produce a controllable * * * equipment foundation information, has been notified to the * * * *, can be produced in the nearby enterprises, with himself informed, have not seen the similar device. You can also instruct the student to write the invention patent application document (the university intellectual property course and the patent attorney don't teach you!) All this is the hard way to raise ticket prices.

- Q:The horizontal distance from the outside edge of the elevator platform and the unloading platform should not be greater than that

- The distance from the cage door to the edge of the layer is less than 50mm. The minimum safe distance between the moving parts of the elevator and the building and the fixed construction equipment such as scaffolding shall not be less than 250mm

- Q:Why is the material advanced air cold and water cooling in the design of the device

- So, water cooling can be cooled to a lower temperature (and air-cooled ratio), so it will be used in the back. The return water temperature of circulating water should not be too high, otherwise it will scale. If it can achieve cooling, it is preferable to save money and save money

- Q:There is no quarterly material transfer label. How do you analyze it in 5

- Plan the flow of information along with the flow of physical flow. Schedule the production and send the processing/outsourcing parts to the follow-up workshop and the post-process, and feedback the actual performance to the planning department. This is a predominantly planning "pusher" logistics management mode, but because of various kinds of interference factors, external demand fluctuations, often running inside often also have exception occurs, all kinds of lead time forecast is not accurate, "plan change lag", leading to each workshop, process between the material quantity and variety in cohesion, the delivery date is hard to meet deadlines. In order to resolve these contradictions, such measures as rapid adjustment plan, safety inventory and emergency feeding are usually adopted. In fact, in production logistics, the enterprise must choose the appropriate management style with the characteristics of its products and production. Other companies often combine the strengths and weaknesses of the above, adopting hybrid strategies such as ERP and JIT management.

- Q:What is the difference between the code for the parts code?

- Each company's management may be different, some companies part code and material code is consistent, in the system, the code can be features of material code only yards, is not necessarily the index. The material coding and the product coding are the only code of the ERP system, the difference is that the material code points to the object, the product code points to the product.

- Q:What are the components of an automated three-dimensional warehouse?

- The second phase, the material can pass all kinds of belt, industrial transport vehicles, robots, crane, stacker and elevator to moving and handling, use shelf tray and removable shelves storage material, through manual operation mechanical access device, with a limit switch, spiral mechanical brake and the operation of mechanical control devices such as monitor. Mechanization satisfies people's requirements for speed, accuracy, height, weight, repeated access and handling.

- Q:The stability of material lift machine mainly depends on which parts of the material hoist

- The stability of material lift machine mainly depends on the material elevator's foundation, the wall rack, the line and the anchor. (1) the foundation of the basic elevator is designed and constructed according to its type and soil quality, so that it can withstand the full load on it. (2) the steel structure between the frame of the frame and the structure of the building is called the attached wall frame. Rigid connections should be adopted and stable structures are formed.

- Q:What needs to be paid for forklift? How to determine the pros and cons of a forklift?

- ?domestic forklift have nearly 50 years of production history is today's quality level and so on have never heard of the brand, must study its strength and background, to make a decision. In the long run, don't focus on the immediate benefits. Now it may be saving some, and it may cost more in the future. 10, if you are still hesitating, please make the manufacturing process (especially the processing level of the details) as the final choice. 11, for no agency shop or individual to be very careful to recommend the brand, because they are usually in accordance with the principle of benefit maximization as well as the relationship with forklift agents to choose, and not recommend to you the price the best brands items

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Automatic Auger Filling Machine for powder and granular

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products