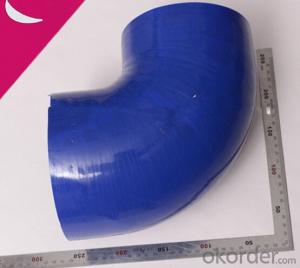

Auto Silicone Hose High Performance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Hebei, China (Mainland)

Name: high quality hydraulic hose made in China for oil

Hose Standard: EN 856 4SP

Inner tube: Oil resistant synthetic rubber

Reinforcement: Four high tensile steel wire spiral

Cover: Abrasion and weather resistant synthetic rubber

Color: Black according to customer's request

Size: 3/4 inch

Temperature: -40-100 ℃

Print words: Customized

Business type: Manufacture

Packaging & Delivery

| Packaging Details: | Sand Blast Hose Package: Hoses are packed with fiber cloth. |

|---|---|

| Delivery Detail: | 15-20days after receive the deposite |

Features

High temperature automotive custom silicone hose features:

1) Working temperature: -40 ~ 240 degrees

2) Reinforcement: Polyester or nomex fabric

3) Color: different color can be provided.

4) Size tolerance: +/-0. 5mm

Application

Mainly used in mine hydraulic support, oil exploration, suitable to engineer construction, crane transport, forging metallurgy, mining equipment, ships, injection molding machinery, agricultural machinery various machine tools.

Our Service

We can offer OEM Services

We can provide FREE SAMPPLE for our customers

We can crimp hose assembly for our customers.

We welcome clients to visit our factory leading to better understanding of our production

FAQ

Q1. Do you produce smooth or cloth wrapped cover?

A. Both, we can produce both cover, which depends on customer’s request.

Q2. Do you produce embossed marking?

A. Yes, we do provide embossed and printing markings with different color.

Q3. Can you produce product with my own brand?

A. Yes, we have been offering OEM services for 20 years.

Q4. Does your product have different color hose?

A. Yes, we currently provide black, grey, red, blue and yellow.

Q5. How long does my order take to be delivered?

A. It usually takes 5 to 30 days, which generally depends on the quantity of your order and our storage.

- Q:What is the essential difference between natural rubber and three yuan ethylene propylene rubber?

- The electric property of natural rubber is a kind of non polar material, and it is a better insulating material. When the natural rubber vulcanization after the introduction of polarity factors, such as sulfur, accelerator, so that insulation performance.The dielectric properties of natural rubber are a nonpolar substance that is soluble in non-polar solvents and non-polar oils. Natural rubber is not resistant to cyclohexane, gasoline, benzene and other media, non vulcanized rubber can be dissolved in the above medium, vulcanized rubber swelling. Natural rubber insoluble in polar acetone, ethanol, more insoluble in water, resistant to 10% hydrofluoric acid, 20% hydrochloric acid, 30% sulfuric acid, 50% sodium hydroxide and so on.

- Q:Three yuan ethylene propylene rubber tube covered with nylon PA66, what glue can not afford the layer?

- The engine parts including inlet system and fuel system, such as engine cylinder cover, solar term door, air filter machine shell, vehicle air horn, automotive air conditioning hose, a cooling fan and a casing, a water inlet pipe, brake oil tank cover and irrigation, etc..

- Q:What is a rubber core pulling method?

- The hose shall be filled with water or gas at a pressure of 0.5 0.8N / mm before pouring concrete. At this point, the hose diameter can be increased by about 3mm. When pouring concrete, the vibrating bar should not touch the hose, and should check the pressure of the water meter regularly. If there is any change, the pressure must be filled.Smoke tube longer than tube core pulling slightly later. Before the pipe is pumped, the water is lowered and the pipe section is reduced, and the pipe can be drawn away from the concrete. The order of pumping is usually first, then first, then first, then straight.

- Q:High pressure hose K type joints KJR32 and KJR31.5D what is the difference between ah, please give us a answer,

- K type joint has the distinction between national standard and German standard. In general, 32 and 38 tubes are used more often. The joints used on 32 of the tubes are KJR32 and KJR31.5D. 38. The joints used on the tubes are KJR38 and KJR B40

- Q:What with the appropriate suction tube Dichotomanthes tube and rubber machine

- The spiral tube called spiral steel tube or spiral welded pipe, the low carbon steel or low alloy structural steel strips in a helical line certain angle (called forming angle) rolled into a tube, then the tube welding seam made up, it can be used in narrow strip production of large diameter steel pipe spiral pipe is mainly used in oil.

- Q:The gas water heater uses metal pipes and rubber pipes

- Gas water heater using metal pipe, good heat resistance, no aging!

- Q:Single ball chloroprene rubber flexible joint, Shanghai Song Jiang rubber ball joint manufacturer where?

- A tubular rubber component is composed of inner and outer layers of rubber, cord and steel ring, which is vulcanized and molded and then combined with a metal flange or a parallel joint. This product can reduce vibration and noise, and can be compensated by thermal expansion and cold contraction due to temperature changes. It is widely used in various piping systems. If I can help you, please accept it.

- Q:Can the high-pressure rubber hose be followed by water pipes? Will it be poisonous?

- The problem should also not large, if it is stored for a period of time in the yard, first put best water again, after all, is not a food container rubber material, inside some substances will dissolve gradually, and there is a water purifier water generating reaction of some harmful substances.

- Q:What kind of material is the rubber tube with acid, alkali and high temperature resistance made of?

- Silicon rubber tube, also known as silicon rubber tube, ordinary silicon hose can withstand temperature of 250 degrees, high temperature resistant material of silicon hose can reach about 350 degrees. And its tear resistance and elasticity are very good. It is widely used in high temperature environment. If you don't understand, you can ask me

- Q:The principle of the common bicycle valve

- When the air pump does not inflate, the elastic rubber tube is tightened to cover the small holes on the side, so that the air can not flow back from the tyre.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Auto Silicone Hose High Performance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords