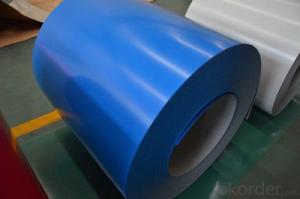

ASTM Z80 Prepainted Galvanized Rolled Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 26000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of ASTM Z80 Prepainted Galvanized Rolled Steel Coil

Description of ASTM Z80 Prepainted Galvanized Rolled Steel Coil

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of ASTM Z80 Prepainted Galvanized Rolled Steel Coil

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of ASTM Z80 Prepainted Galvanized Rolled Steel Coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of ASTM Z80 Prepainted Galvanized Rolled Steel Coil

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+Z, etc |

Thickness | 0.3-4.0mm |

Width | 400-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of ASTM Z80 Prepainted Galvanized Rolled Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each color. And we could give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your can offer the better price we can provide.

2. How long can we receive the product after purchasing?

Usually within thirty working days after received buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15- 25 days, but the shipment will depend on the vessel situation.

3.What kind of terms of payment?

T/T, L/C,D/A,D/P,Western Union are available.

- Q:Can steel coils be used in the production of medical equipment?

- Yes, steel coils can be used in the production of medical equipment. Steel is a versatile material known for its strength, durability, and ability to withstand various environmental conditions. It is commonly used in the manufacturing of medical equipment such as surgical instruments, orthopedic implants, hospital beds, and diagnostic machines. Steel coils are often utilized as a raw material in the production process. They can be processed and formed into various shapes, sizes, and components required for medical equipment. The coils can be cut, shaped, and welded to create intricate parts with precise specifications, ensuring the quality and performance of the final product. Moreover, steel coils can be surface-treated to enhance their corrosion resistance, making them suitable for use in medical environments where cleanliness and hygiene are crucial. Coatings such as electroplating or powder coating can be applied to provide an additional layer of protection against rust and other forms of degradation. Furthermore, steel is a cost-effective material, which makes it an attractive choice for medical equipment manufacturers. Its availability and affordability make it a preferred option for producing high-quality medical devices while keeping the production costs manageable. In summary, steel coils can indeed be used in the production of medical equipment. Their strength, durability, versatility, and cost-effectiveness make them an ideal choice for manufacturing various components and instruments used in the healthcare industry.

- Q:Are steel coils used in appliances manufacturing?

- Yes, steel coils are commonly used in the manufacturing of appliances. They serve as a key component in various appliances such as refrigerators, washing machines, and dryers, providing structural strength and stability to the overall product.

- Q:Please give me the name of the steel, and the percentage of materials from what It consists, if you can give me five types of steel it will be better so I can decide. Thanks.

- Without okorder .. Plus few other useful resources. In the end, there's no one best steel, not even 5. It all depends on the knife design, use, edge thickness, what you cut, etc...

- Q:Is there much difference? Which is better? Are they equally safe? Is it just personal preference? Can you reccomend a good comfortable steel composite toe boot?

- steel toe boots are just that a piece of steel fitted over the toes, composite toe boots use other materials that are just as hard BUT they do not have the connectivity levels as steel. if you are working in a cold climate steel toes will freeze them toes right off, also electrical environments. my advice get a good pair of composite ones, and you get what you pay for, its worth the investment. more than you could ever imagine. proper foot support. helps legs cramps, back pain etc...

- Q:What are the factors influencing the price of steel coils?

- The factors influencing the price of steel coils include the cost of raw materials, such as iron ore and coal, as well as energy prices, transportation costs, labor wages, and market demand. Additionally, exchange rates, trade policies, government regulations, and global economic conditions can also impact steel coil prices.

- Q:Does Steel Cut Oatmeal have the same health benefits as Old Fashioned Oatmeal? What is the difference in processing?

- I have read about steel cut oatmeal, and they say that has the benefit of the whole natural grain, so its more fiber that your getting for your digestion!

- Q:I want to make a chess set out of stainless steel, but I'm not sure what type of mold I need or where I can go to have the steel melted and molded for me. Any ideas? I live in Southern, NJ.

- stainless steel is really hard to work with and will be really expensive to pour as not too many foundries do that. As far as tools go, I know that for e.g.drilling stainless steel cobalt bits are best, but even they don't last for very long. If you use normal drill bits stainless steel will ruin them. So how much metal working skills do you have? I would suggest to use a material you have experience with. Or make a chess set from nuts and bolts. You can buy them from stainless steel and the assembly is easy. See links for a few examples and/or use google to find more.

- Q:How do steel coils contribute to sustainable construction?

- Steel coils contribute to sustainable construction in several ways. Firstly, steel is a highly durable and long-lasting material, which means that structures built using steel coils have a longer lifespan and require fewer repairs and replacements. This reduces the overall environmental impact of construction by minimizing waste and resource consumption. Additionally, steel is a highly recyclable material, and steel coils can be easily recycled at the end of their life cycle, reducing the need for new steel production and conserving natural resources. Furthermore, steel is a fire-resistant material, providing enhanced safety and reducing the risk of structural damage during fire incidents. Overall, the use of steel coils in construction promotes sustainability by minimizing environmental impact, conserving resources, and ensuring the longevity and safety of structures.

- Q:How are steel coils used in the production of automotive parts?

- Steel coils are used in the production of automotive parts as they provide a durable and flexible material for making various components such as body panels, chassis, and suspension parts. The coils are processed through specialized machinery to cut, shape, and form the steel into the required parts, ensuring strength and precision. Additionally, the coils can be treated or coated to enhance corrosion resistance, further improving the longevity and performance of automotive parts.

- Q:How are steel coils used in the production of roofing materials?

- Steel coils are used in the production of roofing materials as they are rolled out and cut into specific dimensions to create metal roofing sheets. These coils provide a sturdy and durable base material that is resistant to weather conditions, ensuring long-lasting and reliable roofing solutions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ASTM Z80 Prepainted Galvanized Rolled Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 26000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords