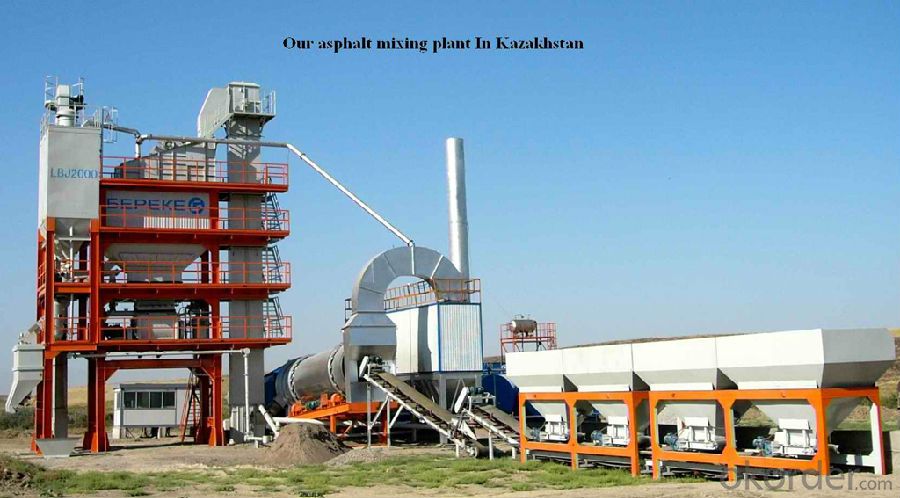

Asphalt&bitumen batching plant LB2000 with capacity 160t/h, bitumen plant in Canada

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification of asphalt&bitumen mixing plant LB2000

| Item | Technical data | ||||

| Aggregate supply system (primary batching device ) | Hopper wall vibrator (2 units) | Motor power | 0.25KW | ||

| Collecting Conveyor belt | Belt width | 650MM | |||

| Productivity | 200T/H | ||||

| Motor power | 4 KW | ||||

| Drying drum | Dimension | 2.3 X 8.2M | |||

| Materials | Steel plate 16/20g | ||||

| Installation angle | 5o | ||||

| Drying drum drive motor | 4 X 15 KW | ||||

| Drying drum rotational speed | 7.7RPM | ||||

| Burning system | Imported oil burner (Optional) | Atomizing medium (optional) | |||

| Model | ZZR2000 (Canada Digi Burner) | ||||

| Power of blower | 15KW | ||||

| Power of oil pump | 2.2KW | ||||

| Screw air compressor | 22KW X 1 | ||||

| Gas consumption | 3M3/MIN | ||||

| Air pressure | 0.6MPa | ||||

| Heavy oil tank | 10T(with oil duct) | ||||

| Diesel tank | 10T(with oil duct) | ||||

| Fuel Type | diesel oil, heavy oil and residual oil | ||||

| Atomizing machinery (optional) | |||||

| Model | EB8N (Italy Burner) | ||||

| Composition | Blower oil,pump,console etc. | ||||

| Heavy oil tank | 10T(with oil supplying pipeline) | ||||

| Diesel tank | 10T(with oil supplying pipeline) | ||||

| Bag dust collector (Optional) | Bag material | NOMEX weight 500g/m2,removing dust easily | |||

| Dust collecting area | 670M3 | ||||

| Air volume | 55000M3/H | ||||

| Compressed air consumption | 2.6M3/MIN | ||||

| Compressed air pressur | 0.4~0.7Mpa | ||||

| Normal working temperature | 100175 | ||||

| Instantaneous max heatresisting | 230 | ||||

| Air compressors | Type | LB150320 | |||

| Motor power | 11KW X 2 | ||||

| Air consumption | 1.67M3/MIN | ||||

| Gas storage tank | 0.6M3 | ||||

| Dust recycling system | Hanging style rotation loader power | 0.75KW | |||

| screw conveyer powert | 4KW | ||||

| Inside spin power | 4KW | ||||

| Recycle powder hoist | 4KW | ||||

| draught fan | Fan motor power | 110KW | |||

| fan wind air volume | 36762~69347M3/H | ||||

| fan wind pressure | 28243874Pa | ||||

| Auxiliary draught fan | Fan motor power | 3kw | |||

| fan wind air volume | 3456~69347M3/H | ||||

| fan wind pressure | 9171210Pa | ||||

| The chimney | Height | 15M | |||

| Exit dust exhaust concentration | <100mg/Nm3 | ||||

| Vibrating screen | Vibration frequency |

| |||

| Amplitude | 6~8MM | ||||

| Screen areas | 18.6 M2 | ||||

| Production capacity | ≥200T/H | ||||

| Drive motor power | 11KW | ||||

| Screen mesh specification | 35X35,22X22,11X11,6X6MM | ||||

| Hot aggregate elevator | Type | duplex chain hopper | |||

| Chain form | double chain ,automatic tensioner | ||||

| Electromagnetic brake motor reducer | Power | 18.5KW | |||

| Chain speed | 1.2M/S | ||||

| Speed reducer power | 15KW | ||||

| Height | 14.8M | ||||

| Hoisting capacity | 200T/H | ||||

| Hot aggregate bin | Type | 4 compartment hoppers | |||

| Hopper volume | 36.7M3 | ||||

| Weighing system | Hot aggregate scale hopper | volume | 2.1 M3 | ||

| Static measuring precision | ±0.5% | ||||

| Weighting modularity sensor | HM-E-A-2 (Meidiya) | ||||

| Powder weighing hopper | volume | 0.41M3 | |||

| Static measuring precision | ±0.25% | ||||

| Weighting modularity sensor | HM-E-A-0.3 (Meidiya) | ||||

| Powder screw conveyer | LSL273×3020×4 | ||||

| Screw conveyer power | 4KW | ||||

| Asphalt weighing hopper | volume | 0.3M3 | |||

| Static measuring precision | ±0.25% | ||||

| modularity sensor | HM-E-A-0.2 (Meidiya) | ||||

| The asphalt measuring pump | 7.5kw | ||||

| The asphalt spraying pump | 11kW | ||||

| Tower frame | Dimension | 8800*2250*2500 | |||

| The mixer | Type |

| |||

| Volume | 2000kg /batch | ||||

| Cycle time | 45s | ||||

| Drive motor power | 37KW×2 | ||||

| Monitor room | Overall dimension | 5M X 2 M X 2.5 M | |||

- Q:What is the daily routine of the concrete mixing station?

- The work of the mixing station is simply the process of production - delivery - construction - curing. Each process consists of the raw materials - the mixing platform - the dispatcher - the on-site technical service. A mature mixing plant are two of the most important department: laboratory and operation department, laboratory to ensure the concrete product quality, operation department to ensure the construction process of concrete delivery smoothly. The other departments serve the two departments.

- Q:What type of concrete mixer is needed for each hour of concrete 90 cubic meters?

- The mixing host of HZS90 concrete mixing station can be matched with the JS double sleeper shaft reinforced concrete mixer or imported concrete mixer host. The host is equipped with dust collecting machine, which has automatic dust collecting, dehumidification, exhaust, and the ability to recycle the collected dust to the main engine. The dust is excellent. The top of the cement bin is equipped with cylinder dust collecting machine, which is efficient and low noise. The main frame is packed in color plate, neat, beautiful and dustproof, with good view. Double post integrated installation, convenient operation and economical site. HZS90 concrete mixing station, the theoretical productivity of the device is 90 cubic meters per hour. The mixing host is the JS1500 type strong mixer, the nominal capacity is 1500L. The toppings are 1600L, the maximum productivity of the screw conveyor is 80t/h, and the maximum particle diameter is 80mm. Cement weighing accuracy and range (0 ~ 900) plus or minus 1% kg, admixtures weighing accuracy and range (0 ~ 50) plus or minus 1% kg, aggregate weighing range and precision of 0 x 5000 plus or minus 2%, HZS90 commodity concrete mixing station - unloading height is 3.8 meters, can be appropriately increase or decrease in height, in order to satisfy the demands of discharge conveyor. The standard reference weight is 97 x 103kg, which needs strong base to stabilize the mixing station

- Q:What is the concept of on-site concrete mixer station

- The concrete mixing station is at the construction site to set up a soil mixing concrete equipment, including automatic conveying equipment, measuring equipment, concrete mixing equipment, cement storage warehouse etc.

- Q:Which staff does the concrete mixing station need?

- Mainly depends on how much station, whether can fully staffed, mainly included: general manager, deputy general manager, technology, webmaster, laboratory (deputy) director of the general, the production manager, sales managers, salespeople, scheduling, lab team leader, the operator (inspection), quality inspection, proportioning design, the material inspector technicians, machine operators, resposible, site, monitor of overhaul, maintenance engineer, loadometer, finance, cashier, mixers, pump truck drivers, company drivers, forklift driver, the handyman, chef, etc.

- Q:Concrete mixstations belong to no special equipment

- The boiler is a special equipment in the stirring station.

- Q:Does the concrete mixing station name have the name of the businessman concrete

- Yes, concrete means artificial stone, which can be understood as the simple writing of concrete, which means concrete for commercial concrete. This is the name of the blender

- Q:What are the facilities of the concrete mixing station

- It can be divided into five large parts of the mixing host, material weighing system, material conveying system, material storage system and control system

- Q:What is the concrete of the mixing station?

- What else can you do to sell concrete What is the station

- Q:What is the difference between a concrete mixer and a concrete mixer

- The simple point is: the bones of the mixing tower are on top, and the bone is measured directly into the blender. The bone material of the stirring station is below, and the bone material is measured and then transported into the blender after the slanting belt. In a popular way, it is called the building, which is called the second ascent. Higher initial investment mixing floor production line 400000 station, because of mixing building bin above, therefore the steel structure will be bigger, inclined belt will be relatively longer. But in productivity, the churn is about 20 per cent more productive. In the operation, the energy consumption and the failure rate will increase due to the frequent start of the inclined belt of the mixing station, while the mixing building will be relatively low. Of course, in appearance, the mixing building is a bit more imposing than a mixer-stand, which can sometimes have an unexpected effect on the business. In addition, there are some technology mixing buildings that can be used, and the mixing stations can't be used, because the equipment is different. It's worth noting that the difference between the initial and the mixing stations is not absolute.

- Q:What chemical materials are used in the concrete mixing station?

- Start with the glue: cement, coal ash, mineral powder, and various expansions! Sand: natural sand, mineral sand, fine sand; Stone: 5-10, 5-20 water reducer! And tap water

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Asphalt&bitumen batching plant LB2000 with capacity 160t/h, bitumen plant in Canada

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords