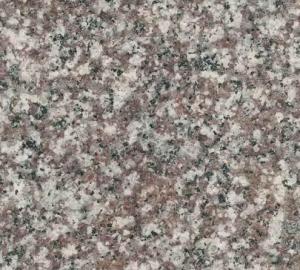

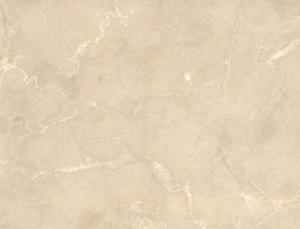

Artificial Stone 023

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000SQM m²

- Supply Capability:

- 3000SQM/Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Key Specifications/Special Features Of Articicial Stone:

1. Material: Stone

2. 2. Antique feel, Metal Image

3. Low water absorption

4. Strong in hardness

5. Coordination in color and luster

6. Usage Area: home, office, hotel, government

7. Style: simple, classic, elegant and splendid in color

8. Good in abrasion and chemical corrosion-resistant

9. Resistance to thermal shock

10. Available in various sizes and colors

Primary Competitive Advantages Of Artificial Stone:

1. All product of rustic ceramic tiles are of top grade AAAA

2. CE certificate, ISO9001:2008 and ISO14001:2004

3. OEM accepted.

4. Speial dimensions available according to your floor tiles request.

5. Best Quality with best price, strictly quality control.

6. On time delivery, in general 7-10days.

7. Best after sale service, customer can follow their porcelain tiles order situation any time. no matter on product line, warehouse or shipment.

Main Export Markets Of Artificial Stone:

1. Asia

2. Australasia

3. Central/South America

4. Eastern Europe

5. Mid East/Africa

6. North America

7. Western Europe

Specification Of Artificial Stone

Artificial Stone Physical Technical Data | |

Compressive Strength | 12.8 Mpa |

Rupture Strength | 3.4 Mpa |

Water Absorption | < 18% |

Drying Shrinkage | 0.5 mm/m |

Freezing resistance (Minus 20 Degrees Celsius ) | Weight Loss:0.75% |

Compressive Strength:10.7Mpa | |

Density | 1120 kg/m3 |

Product Pictures Of Artificial Stone

- Q:Do you want to keep the board under the marble panel?

- 1, from the mechanical point of view, because the artificial stone in the horizontal plane has a certain degree of flexibility, without pad is to use the cabinet itself to bear the weight of the frame, encountered a larger scale cabinet, over time, there will be bump Phenomenon, especially the high resin content of artificial stone, deformation is very obvious. 2, in addition to the mat, to avoid the emergence of the above situation, but the stability of the workers by the discharge pad of the decision, from the environmental considerations, each pad are sealed on the side, the cost is greater than the pad, Therefore, the responsible manufacturers, will be in the table under the mat to reach the e1 level, and the closure of the whole board.

- Q:Cabinets are quartz stone or artificial stone ah? In the end there are advantages and disadvantages

- Artificial stone is roughly divided into artificial acrylic stone and artificial quartz stone, of course, there are some new stone, but basically a small group, each business from the different names and bad classification. Acrylic stone and quartz stone is nothing good or bad, the composition of different, the characteristics of the difference is relatively large, so in the purchase, to clearly compare their own characteristics of the table, to the acrylic or quartz stone choice.

- Q:Artificial marble on the stains, how to clean up?

- For oil traces, use ethanol (alcohol), acetone (wood fine) or lighter oil wipe, and then clean and dry. If the marble furniture was spilled with coffee, or was burned by the cigarette butts, should be considered to repair.

- Q:Artificial marble countertop thickness is conventional

- Width range of 960mm (highest), including standard width: 960mm;

- Q:What is the prospect of man-made stone market? What about profit?

- Site selection need to have some understanding of the market place, such as the factory hometown, the factory can not provide. Equipment purchase: As the artificial stone processing equipment sales more, each factory is due to different regions, choose the nearest place to buy equipment is more reasonable.

- Q:Artificial stone countertops how to deal with stains

- With the finest sandpaper, stained with water, slightly polished about. And then rub very clean. After treatment is best on a layer of stone maintenance, buy a large box on their own on the line.

- Q:What kind of man-made stone is high in hardness

- Do not know what you are doing, if it is a cabinet, you can choose acrylic or quartz stone countertops.

- Q:Which factory is the lowest price

- Hinge, pull basket, handle, track replacement. Can be customized to do the whole cabinet (or alone do artificial stone, quartz stone countertops, door, cabinet).

- Q:What is the composition of artificial stone?

- Most of the artificial stone products on the market belong to this category.As the manufacturers of the scale of production, technology, technology, equipment and other great difference, the choice of raw materials ranging from good or bad, resulting in the cost of the product ranging from direct impact on the product Price and quality of the market price of about 400-700 yuan / m.

- Q:What is the man-made stone of the countertops?

- Acrylic stone and quartz stone is the two main types of artificial stone classification, quartz stone density is hard and hard, it is said that its hardness after the diamond, so good wear resistance, and beautiful texture, low cost. But there are shortcomings such as easy accumulation of grease, can not be formed, the gap is easy to breed bacteria and so on. In addition, man-made stone is made of non-natural mixture, such as resin, cement, glass beads, alumina powder, etc. plus gravel adhesive. Advantages are acid, high temperature, impact resistance, rich color. More important feature is easy to shape the whole.

1. Manufacturer Overview |

|

|---|---|

| Location | Foshan, China |

| Year Established | 2000 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | Aisa; Mid East; Eastern Europe; North America; South America |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Foshan;Huangpu |

| Export Percentage | 30% - 40% |

| No.of Employees in Trade Department | 10-15 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Medium |

Send your message to us

Artificial Stone 023

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000SQM m²

- Supply Capability:

- 3000SQM/Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords