High Quality Low Carbon stone 001

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 sq.m. m²

- Supply Capability:

- 400000 sq.m. Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General information of low carbon stone

|

Raw material |

Sawdust, corn-straw and tailing, can be recycled after using. |

|

Technology |

Utilizing molecular structure of crystalline-state solidification, shaping under normal temperature and pressure with low carbon emission. |

|

Installation |

Stitching, wet-sticking and dry-fasten connecting |

|

Character |

Favorable corrosion resistance, non-ignitable, water-proof, UV-resistant, high resistance to fire, water and insects. |

|

Lead time |

30 days after receiving buyer's original L/C or Prepayment |

|

Package |

Seaworthy Export Standard Wooden Pallet |

|

Four breakthroughs |

Comprehensive utilization of natural resources: Be recyclable, using sawdust, corn-straw and tailing as materials. The product can be recycled after using. |

|

Low carbon and energy saving in the course of production: Adopting the independent individual property’s technology, utilizing molecular structure of crystalline-state solidification, shaping under normal temperature and pressure with low carbon emission. | |

|

Environmental and healthy in the course of construction and using: Synthesized by natural inorganic raw materials, nontoxic, odorless and non-radiative simple installation, which could save energy cost and reduce and waste emission, raise efficiency and reduce erection time. | |

|

From nature, beyond nature: Full realization of the natural texture, high resistance to fire, water and insects. Do not rot or fade after long time usage. Super self-cleaning needs low maintenance cost. Vivid color and appearance provides a wide space to designers. | |

|

Six advantages |

Lower more than 50% cost, enhance building's performance to price ratio. |

|

Cutting at will, Fixing easy, Shorting project time. | |

|

Good performance in resistance to elements, corrosion-resistant ,resistance to termite, fire resistance and water-resistant, far from distortion and discolorations in 30 years. | |

|

Well self-cleaning, low cost in later maintenance: Don't need professional maintenance in 30s(Cleaning with water only), saving much cost. | |

|

Customize the color, showing individuation: Beyond 400 kinds of colors, designers could exhibit their imagination. | |

|

Compound with natural inorganic materials: Without formaldehyde and toluol, sustained releasing negative oxygen ion, forming nature oxygen bar. | |

|

Special specifications are available on customers' requirements. | |

Technical information of low carbon stone

|

Density |

1.23 g/m3 |

Folding strength |

15.4 Mpa |

|

Wet expansion rate |

0.32% |

Shear strength |

3.5Mpa |

|

Frost resistance |

Thaw-freeze cycle after 25 times, no slip crack and peeling off | ||

|

Formaldehyde release |

0.014mg/(m2·h) (GB/T 18587-2001) | ||

Specification of low carbon stone

Standard: 2400mm/3000mm(L)×1200mm(W)×12mm/20mm(T)

Standard length: 2400mm/3000mm

Standard width:300mm,400mm,600mm(including 3mm kerf width)

Standard thickness: 12mm/20mm

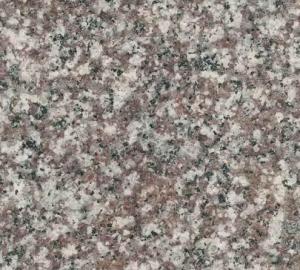

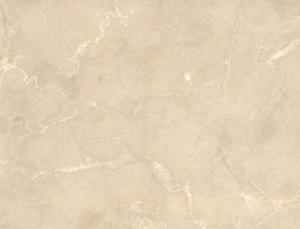

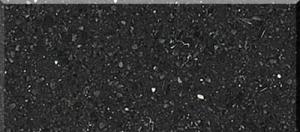

Product exhibition of low carbon stone

Low carbon stone with hole rock

Low carbon stone

The project picture of low carbon stone

- Q:Kitchen with natural marble and artificial marble which is good

- Due to the physical and chemical characteristics of artificial stone, a few meters long stone in the field construction can be seamless splicing, no scar mark, where the eyes are smooth curve. Construction technology is not complicated, artificial stone raw materials are mainly natural stone powder polyester resin, color pigments and aluminum hydroxide, so do not worry about the radioactive stone.

- Q:What are the artificial stone countertops?

- Crystal stone: crystal stone compared to the essence of stone in the nature and not much change, but in the color, paint more use of large particles, high transparency of the material.

- Q:What are the types of artificial stone?

- The market also appeared a lot of price in the 400-600 yuan / m artificial stone. According to the normal quality requirements of man-made stone and can guarantee the quality of raw and auxiliary materials prices, cost projections, the man-made stone of the two main materials are likely to cut corners, with low resin, aluminum hydroxide and calcium carbonate Instead, it is the primary means of reducing costs. Known as calcium carbonate artificial stone, the market is about 95% of artificial stone are inferior calcium carbonate artificial stone (also appeared a lot of calcium carbonate artificial sale of high prices, more deceptive).

- Q:Artificial stone is usually divided into several types?

- Crystal plate and ordinary board, the biggest difference is that the crystal version is translucent, ordinary board opaque.

- Q:Whether the table is made of natural marble or man-made marble

- With the development of modern architecture, the decorative materials made of light, high strength, beautiful, multi-species requirements. Artificial surface stone is in this situation appears. It is light weight, high strength, corrosion resistance, pollution resistance, easy construction, pattern patterns can be artificially controlled, is the ideal building materials for modern architecture.

- Q:Home improvement artificial stone is good or marble a little better

- Artificial marble: color and more, decorative good color is not natural light quality, durability, poor resistance to corrosion, pollution, texture is soft, the price is not high temperature natural marble: color natural, atmospheric corrosion resistance to high temperature radiation, Big deformation, durable

- Q:Artificial stone pattern how to do it

- 1. Appearance - smooth surface, no pores, linen and other defects, beautiful colors, the substrate surface should have a sense of particle suspension, with a certain degree of transparency. 2. Physical, chemical properties - with sufficient strength, stiffness, hardness, especially the impact resistance, anti-scratch is better. 3. Durability - with weather resistance, dimensional stability, resistance to deformation and resistance to cold quenching heat.

- Q:What is the prospect of artificial marble now? Have you ever known?

- Artificial marble prospect is good, according to the prospective industry research institute "2016-2021 China marble industry market prospecting and investment strategic planning analysis report" shows that man-made marble from natural marble powder re-processing, with many natural marble characteristics, , Gloss and wear resistance are better than the natural marble, artificial marble color, texture, delicate, lighter weight, there is no color between the same color and radioactive material. And man-made marble in the moisture, acid, alkali, high temperature, piecks have made great progress.

- Q:Artificial stone is fragile?

- 1. The main component of marble is calcium carbonate, which caused the marble is very easy to break. 2. Marble will release a gas called radon, which will cause harm to the human respiratory tract, but there is no problem as long as air circulation is maintained. 3. Marble can not be seamless stitching, once encountered a longer size when the marble and marble interface is easy to be seen, even if the plastic, with the same cornea grinding. 4. Marble after a long period of sun will appear after the fade of the situation. 5. The density of the marble is low and the dirt is easy to penetrate into it.

- Q:How to make artificial stone countertops with double - layer composite process

- The cementitious material is subjected to sawing, coarse grinding, drying and heating to 55 to 75 ° C. Diluted artificial stone resin and curing agent are carried out on a cement board surface by means of a scraper or spray method. 0.15 -0.3 mm thickness Of the compound.

1. Manufacturer Overview |

|

|---|---|

| Location | Tianjin,China |

| Year Established | 2009 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 11% - 20% |

| No.of Employees in Trade Department | |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 500,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | High;Average |

Send your message to us

High Quality Low Carbon stone 001

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 sq.m. m²

- Supply Capability:

- 400000 sq.m. Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products