APP/SBS Basement Waterproofing Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product description:

Item | APP/SBS Basement Waterproofing Membrane | |||||

Brand | CNBM | |||||

Grade | First | Second | ||||

Base | PY | G | PYG | |||

Cover | PE | S | M | PET | ||

Thickness | 2/2.5/3/3.5/4mm | |||||

Color | Black PE film | Yellow/Green/Red/Other Fine Sand | Grey/Green/Red/Other Mineral/Grains/Flakes | Aluminium Foil | ||

Notes | PY------Polyester Base G------Glassfibre Base PYG------Glassfibre Reinforced Polyester Base | |||||

Characteristic

a)Good impermeability

b)SBS modified bitumen membrane is specially being applied in the cold area with low temperature

c)Good performance in anti-puncture, anti-broker, anti-resistance, anti-erosion, anti-mildew, anti-weathering

d)Possess good tensile strength, elongation rate and size stability which could be well suited the substrate distortion and crack

Applicable scope

Suitable for civil building roofing, underground, bridge, parking, pool, tunnel in the line of waterproofing and dampproof, especially for the building under high temperature. According the roofing engineering stipulation, APP modified bitumen membrane could be used in the Grade I civil building and industrial building which has special waterproofing requirement

There are two methods in application

a) One way is by heating and melting method.Heat the polyethylene film of the membrane and roof deck surface by heating and melting method to be nearly melted (not flowing),then install the membrane filly bonded to the roof deck with overlaps of 5-10cm.

b) The other way is by cold adhesive method.Pour the cold adhesive homogeneously on the roof deck, then roll the membrane to install it to be fully sticked to roof deck.

By heating and melting method and by cold adhesive can be used in alternation in application as requested.

c)After application,a full serious inspection is required to sure no air bubble,no falling away.etc. to guarantee the waterproof life.

Attentions for construction

Construction shall not be carried out in rain, snow or over 5 degree wind weather; Thereshall be sufficient safety protective facilities in construction site, place firefighting devices according to stipulations

1)Clean the substrate using broom or high pressure dusty cleaner

2)Apply primer

3)Heat the membrane bottom using a high temperature flame gun

4)Push forward while the primer and membrane oil melted

5)Use a roller to push hard the membrane surface to ensure it stick firmly

Technical parameter

| Item | Specifications | ||||||||

| Geotextile Unit Weight (g/m²) | 300 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | |

| Geomembrane Thickness (mm) | 0.25-0.35 | 0.30-0.50 | |||||||

| Nominal Fracture Strength (KN/m) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Breaking Strength (KN/m,≥,LD/TD) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Standard Intensity Corresponding Elongation Rate (%) | 30~100 | ||||||||

| CBR Burst Strength (KN,≥) | 0.70 | 1.50 | 1.90 | 2.20 | 2.50 | 2.80 | 3.00 | 3.20 | |

| Longitudinal Tear Strength (KN,≥) | 0.05 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| Hydrostatic Pressve (Mpa) | See List Below | ||||||||

| Peel Strength (N/cm,≥) | 6 | ||||||||

| Vertical Permeability Coefficient (cm/s) | According to design or contract mentioned. | ||||||||

| Width Variation (%) | -1.00 | ||||||||

| Item | Geomembrane Thickness (mm) | ||||||||

| 0.20 | 0.30 | 0.40 | 0.50 | 0.60 | 0.70 | 0.80 | 1.00 | ||

| Hydrostatic Pressve (Mpa) | One geotextiles with one geomembrane | 0.40 | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 |

| Two geotextiles with one geomembrane | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 | 1.80 | |

Our Services

1.If you need some advises for the waterproof construction, we have the best engineer to serve you.

2.We send the free samples to you by freight collect.

3.We will guarantee the quality and the competitive price.

4.We will give you the best packaging and safe shipping.

5.If any problem, we will always be right here waiting for you.

Product usage of pe compound waterproof membrane

The products are widely used in projects of compound geomembrane impervious

product show

Product line&test

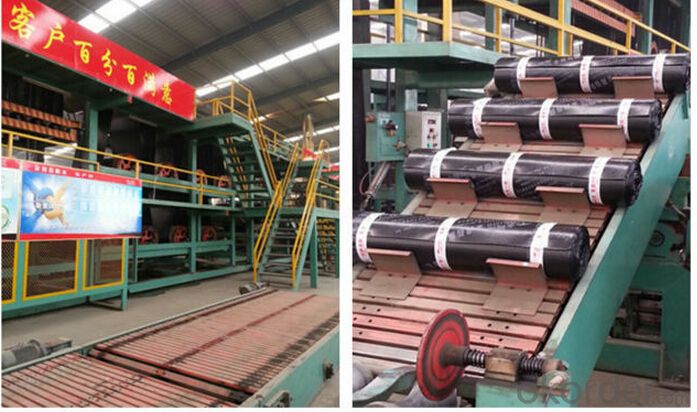

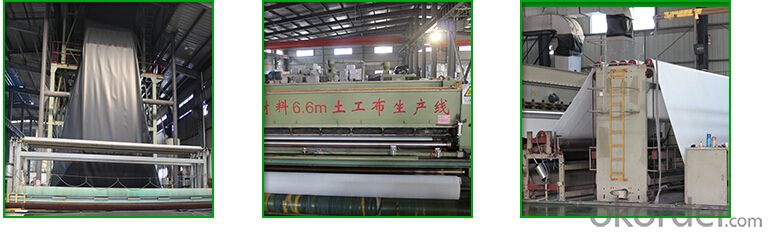

♦Product line

From raw materials to finished products, every process is tested and controlled professionally and seriously by our professional machines and person.

Professional test machines ensure the products qualified roduct certifications

roduct certifications

Inquiry Note

How to send an effective inquiry for saving your time?

Packaging & Shipping

Factory show

FAQ

- Q:What is the cost of installing a waterproofing membrane?

- The cost of installing a waterproofing membrane can vary depending on various factors such as the size of the area to be waterproofed, the type of membrane being used, and the complexity of the installation process. On average, the cost can range from $3 to $10 per square foot. However, it is important to note that this is just a rough estimate and the actual cost can be higher or lower depending on the specific requirements of the project. It is recommended to consult with a professional waterproofing contractor to get an accurate cost estimate tailored to your specific needs.

- Q:Are waterproofing membranes resistant to freeze-thaw cycles?

- Yes, waterproofing membranes are designed to be resistant to freeze-thaw cycles. They are specifically manufactured to withstand the expansion and contraction caused by freezing and thawing without compromising their integrity or performance. This resistance ensures that the membranes remain effective in preventing water infiltration and maintaining the durability of the structure they are applied to.

- Q:Can waterproofing membranes be used on metal surfaces?

- Indeed, it is possible to utilize waterproofing membranes on metal surfaces. The purpose of waterproofing membranes is to establish a barrier that obstructs the infiltration of water into surfaces, regardless of their composition. Since metal surfaces are susceptible to corrosion and water-related harm, the application of a waterproofing membrane can safeguard them against moisture and prolong their lifespan. The choice of waterproofing membrane may vary depending on the precise needs and specifications of the metal surface; nevertheless, there are several options specifically engineered for metal applications. These membranes typically possess flexibility, durability, and resistance to UV rays and other environmental factors, thereby ensuring enduring protection for the metal surfaces.

- Q:Can a waterproofing membrane be applied to wood surfaces?

- Yes, a waterproofing membrane can be applied to wood surfaces. There are various types of waterproofing membranes available on the market, such as liquid membranes or sheet membranes, that can be specifically designed for wood surfaces. These membranes are typically made of materials like rubber, asphalt, or polyurethane, which provide a protective barrier against water and prevent moisture from penetrating the wood. The waterproofing membrane is applied to the wood surface using different methods, depending on the product, such as brushing, rolling, or spraying. Applying a waterproofing membrane to wood surfaces can help prolong the lifespan of the wood, prevent rotting or warping, and protect it from water damage. However, it is important to ensure proper surface preparation and follow the manufacturer's instructions for application to achieve the best results.

- Q:Can a waterproofing membrane be applied to metal surfaces?

- Metal surfaces can indeed benefit from the application of a waterproofing membrane. These versatile membranes are suitable for use on a range of materials, including metals. Their primary purpose is to safeguard metal surfaces against corrosion and water-related harm. By acting as a barrier, these membranes effectively ward off moisture infiltration, preventing rust and deterioration. Moreover, they can even enhance insulation and bolster the overall durability of the metal surface. To guarantee secure adhesion and enduring protection, it is crucial to select a waterproofing membrane explicitly designed for metal surfaces.

- Q:Can a waterproofing membrane be used on concrete block surfaces?

- Yes, a waterproofing membrane can be used on concrete block surfaces. It is commonly used to prevent water penetration and protect the underlying structure from moisture damage.

- Q:How to distinguish whether the waterproofing membrane is polyester tires?

- Waterproof membrane requirements have good water resistance, stability of the temperature change (high temperature does not flow, no blistering, not confuse; low temperature does not brittle crack), a certain mechanical strength, extensibility and resistance to fracture, to There is a certain degree of flexibility and anti-aging and so on.

- Q:Can a waterproofing membrane be used on metal block surfaces?

- Yes, a waterproofing membrane can be used on metal block surfaces. Waterproofing membranes are designed to create a barrier against water and moisture, and they can be applied to a variety of surfaces, including metal. The membrane will adhere to the metal surface, creating a waterproof layer that helps prevent water infiltration and protect the metal from rusting or corrosion. However, it is important to ensure that the metal surface is clean, dry, and properly prepared before applying the waterproofing membrane to ensure proper adhesion and effectiveness. Additionally, it is recommended to consult with a professional or refer to the manufacturer's instructions for specific guidance on using a waterproofing membrane on metal block surfaces.

- Q:Can a waterproofing membrane be used on roofs with standing water or ponding?

- No, a waterproofing membrane should not be used on roofs with standing water or ponding. Standing water can put excessive stress on the membrane and compromise its effectiveness, leading to leaks and water damage. It is important to address and correct any ponding issues before applying a waterproofing membrane to ensure its long-term performance.

- Q:Can a waterproofing membrane be used for walkways or pedestrian bridges?

- Yes, a waterproofing membrane can be used for walkways or pedestrian bridges. Waterproofing membranes are designed to protect surfaces from water infiltration and can be applied to various structures, including walkways and pedestrian bridges, to prevent water damage and ensure their longevity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

APP/SBS Basement Waterproofing Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords