Aluminum Window and Door Frame and Profile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.1

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Frame

Products Introduction

Aluminum frame is made from aluminum and minerals. It's raw matrial for window frame, window frame, and other equipment frame. It's easy for construction, cost less, service longer than other materails. The size and design can be customerized.

Advantage of Aluminum Frame

-Build FLEXIBLE equipment, window, door.

-Bolt your structure together

-Build with Aluminum MORE EASILY

-Aluminum costs LESS

-Service life is more than 10 years

-Can be customerized

Specifications

(1) Product: Aluminium Frame;

(2) Material: Alloy 6063/6061/6005/6060, T5/T6;

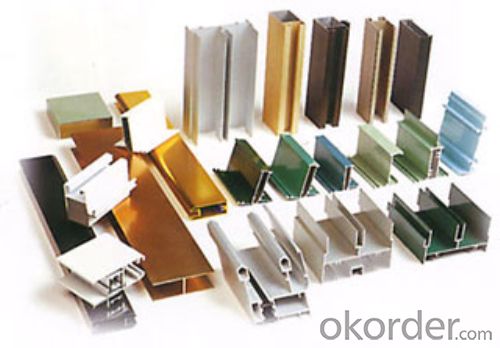

(3) Finish: anodizing, powder coating, wooden, electrophoresis or any color;

(4) Size: customized, same as drawings or samples;

(5) Standard: High-quality;

(6) Characteristics: strong, stylish, durable, corrosion-resistant.

Aluminium Alloy: 6063, 6061, 6005, 6060 Thermal Treatment: T5, T6

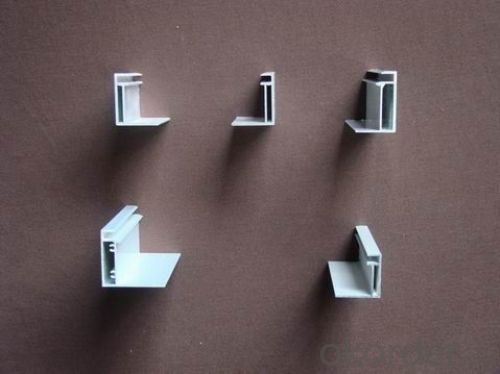

Section Shapes

I, U, T, C, Z, L, H, square, round, flat, hollow, t-slot, and other complicated shapes by custom design.

Surface treating

Mill / Anodizing (oxidation) / Sand blasting / Powder Coating / Electrophoresis / PVDFCoating / Wood effect.

Application

1) - for Window and door frames, for Wardrobe cabinet sliding doors, kitchen, for Building curtain glass walls

2) -for Fencing, Rail, Deck and Frame.

3) - for Solar panel frames, solar mounting / roofing brackets

4) - for Industry assembly lines equipment.

5) - for Heatsinks, for LED lighting.

7) - other by custom design size and dimension

FAQ

-What's your company profile?

We CNBM is the largest building material supplier of China. We are Chinese government owned corporation, which takes the 267th place in WOLD FORTUNE 500 CORPORATION. We own the largest prodcution base in North and South of China. With more than 15 warehouses and offices in different countries, our products sell very well all over the world. We have whole quality control system. We'll be your reliable partner.

-Which kind of payment do you usually support?

TT, LC at sight.

-Can you provide samples?

Yes, we provide free of charge samples, you just need to pay for the delivery.

Photos:

- Q:The surface of pure aluminum is relatively soft, too hard to be machined, and the other to be polished. If you want to harden the aluminum parts you produce. What's the way?. Please expert pointing

- anodic oxidation6063 is not pure aluminum, in order to harden can consider aging, aluminum extrusions mainly through air-cooled quenching and aging to achieve T5 processingOn the surface, several um thickness alumina protective layers can be formed to improve corrosion resistance and wear resistance. In addition, if you can change materials, you can choose 2024T4 (Ying Lv).

- Q:Are aluminum profiles suitable for conveyor rollers?

- Yes, aluminum profiles are suitable for conveyor rollers. Aluminum is a lightweight and durable material that offers various advantages for conveyor systems. Firstly, aluminum profiles provide excellent strength-to-weight ratio, making them ideal for conveyor rollers. They are strong enough to handle the weight of materials being transported while being light enough to reduce the overall weight of the conveyor system, resulting in energy savings and easier handling during installation and maintenance. Additionally, aluminum profiles offer excellent corrosion resistance, which is crucial for conveyor systems operating in harsh environments, such as those exposed to moisture or chemicals. This corrosion resistance ensures the longevity and reliability of the conveyor rollers, reducing maintenance requirements and costs. Moreover, aluminum profiles can be easily customized and fabricated to fit specific conveyor system requirements. They can be extruded into various shapes and sizes, allowing for the creation of conveyor rollers that perfectly match the application's needs. This versatility makes aluminum profiles highly adaptable and suitable for a wide range of conveyor systems, including those in industries such as manufacturing, packaging, and logistics. Furthermore, aluminum is a highly sustainable material as it is 100% recyclable, making it an environmentally friendly choice for conveyor rollers. By using aluminum profiles, companies can contribute to their sustainability goals and reduce their carbon footprint. In conclusion, aluminum profiles are indeed suitable for conveyor rollers due to their lightweight, durable, corrosion-resistant, customizable, and sustainable properties.

- Q:What are the different surface patterns available for aluminum profiles?

- There are several different surface patterns available for aluminum profiles, each offering unique aesthetic and functional benefits. Some of the most commonly used surface patterns include: 1. Smooth: This is the most basic surface pattern, with a smooth and polished finish. It provides a sleek and modern appearance, making it ideal for applications where aesthetics are important. 2. Brushed: This surface pattern is characterized by fine lines or brush strokes running in a single direction. It creates a textured and satin-like appearance, which is often chosen for its contemporary and industrial appeal. 3. Anodized: Anodizing is an electrochemical process that creates a durable and corrosion-resistant surface on aluminum profiles. It can be customized to produce various colors and finishes, such as matte, glossy, or metallic. 4. Powder-coated: Powder coating involves applying a dry powder onto the aluminum surface and then heating it to create a smooth and durable finish. This process allows for a wide range of colors and textures, including matte, glossy, and textured finishes. 5. Wood grain: By using a specialized printing process, aluminum profiles can be made to mimic the appearance of wood. This surface pattern offers the natural and warm look of wood, while providing the benefits of aluminum, such as durability and low maintenance. 6. Textured: Aluminum profiles can also be given a textured surface pattern, which can range from a fine sand-like texture to a more pronounced embossed or hammered look. Textured surfaces not only enhance the visual appeal but also provide better grip and slip resistance. These are just a few examples of the many surface patterns available for aluminum profiles. The choice of surface pattern depends on the specific application requirements, desired aesthetics, and functional needs.

- Q:Aluminum profile CAD drawings

- Aluminum section, designers can directly call the drawing, wide application and machine Association, electronic equipment, instrumentation equipment, aluminum plating process, which belongs to the coating technology it is pre plating and electroplating process steps to increase on the basis of conventional Ti process, aluminum is the process of the aqueous solution of salt and hydrochloric acid in the plating the activation of chemical treatment; electroplating bath composition including nickel sulfate, nickel chloride, boric acid, twelve sodium lauryl sulfate, saccharin, brightener, this process has the advantages of simple, practical and good effect etc.

- Q:Can aluminum profiles be used in marine environments?

- Yes, aluminum profiles can be used in marine environments. Aluminum is often chosen for its excellent corrosion resistance and lightweight properties, making it ideal for marine applications. It is commonly used in the construction of boats, shipbuilding, and offshore structures due to its durability and ability to withstand exposure to saltwater and harsh weather conditions.

- Q:What are the different surface embossing options for aluminum profiles?

- Aluminum profiles offer a variety of surface embossing options, each with its own unique textures and patterns. Some commonly used options include: 1. Diamond pattern: This option creates a diamond-shaped pattern on the profile's surface, providing both visual appeal and improved grip. It is ideal for applications that require slip resistance. 2. Stucco pattern: Stucco embossing creates a textured surface with small, raised bumps. It is often used in applications where aesthetics play a crucial role, such as architectural facades or interior design elements. 3. Hammer tone pattern: This option gives the aluminum profile a hammered texture, providing a distinctive and rustic appearance. It is popular in decorative applications like furniture or light fixtures. 4. Wood grain pattern: Wood grain embossing mimics the texture and look of natural wood. It is commonly chosen for applications like window frames or doors when a traditional or natural appearance is desired. 5. Linen pattern: Linen embossing creates a subtle, fabric-like texture on the profile's surface. It is frequently used in applications that require a sophisticated and elegant finish, such as interior decorative panels or cabinet doors. It's worth noting that these embossing options can be customized or combined to meet specific design requirements. Manufacturers may offer additional options, allowing customers to choose from a wide range of patterns and textures to achieve their desired aesthetic and functional goals.

- Q:What are the specific features of industrial aluminum profiles?

- Abrasion resistance, corrosion resistance, anti oil Department of Chongqing Lixing

- Q:Are aluminum profiles suitable for greenhouse structures?

- Yes, aluminum profiles are highly suitable for greenhouse structures. They are lightweight, durable, and resistant to rust and corrosion, making them ideal for outdoor environments. Additionally, aluminum profiles offer excellent strength and flexibility, allowing for easy customization and assembly of greenhouse structures.

- Q:How do aluminum profiles perform in earthquake-resistant structures?

- There are numerous advantages of using aluminum profiles in earthquake-resistant structures. Firstly, aluminum is a lightweight material, meaning it possesses a high strength-to-weight ratio. This quality enables aluminum profiles to provide exceptional structural integrity while minimizing the overall weight of the building. This becomes particularly important in areas prone to earthquakes as it reduces the forces exerted on the structure during seismic events. Furthermore, aluminum exhibits high ductility, allowing it to deform significantly without losing its strength. This property enables aluminum profiles to absorb and dissipate seismic energy, effectively reducing potential damage to the structure. Additionally, the ductility of aluminum ensures its ability to withstand the lateral forces and vibrations generated during an earthquake, providing enhanced stability to the building. Moreover, aluminum profiles possess outstanding corrosion resistance, making them ideal for earthquake-resistant structures in coastal regions or areas with high humidity. This corrosion resistance guarantees the durability and longevity of the structure, even in harsh environmental conditions. Additionally, aluminum profiles can be easily fabricated and assembled, offering versatility in design and construction. This flexibility allows architects and engineers to optimize the structural performance of the building, taking into account the specific seismic requirements of the region. In conclusion, due to their lightweight nature, high strength-to-weight ratio, ductility, corrosion resistance, and ease of fabrication, aluminum profiles excel in earthquake-resistant structures. These characteristics make aluminum profiles a dependable choice for ensuring the safety and stability of buildings in areas prone to seismic activity.

- Q:Can aluminum profiles be used in the construction of exhibition stands?

- Yes, aluminum profiles can be used in the construction of exhibition stands. Aluminum profiles are lightweight, durable, and easy to work with, making them a popular choice for building exhibition stands. They can be easily cut, shaped, and assembled to create custom designs that meet the specific requirements of the exhibition. Additionally, aluminum profiles can be powder-coated or anodized to provide a wide range of finishes, enhancing the aesthetic appeal of the exhibition stand. Furthermore, aluminum is resistant to corrosion and can withstand various weather conditions, ensuring the longevity of the exhibition stand. Overall, using aluminum profiles in the construction of exhibition stands offers flexibility, durability, and a sleek appearance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Window and Door Frame and Profile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.1

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords