Aluminium Profile for Cars Auto-parts Good Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Aluminium Profile for Cars Auto-parts Good Quality Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile for Cars Auto-parts Good Quality:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

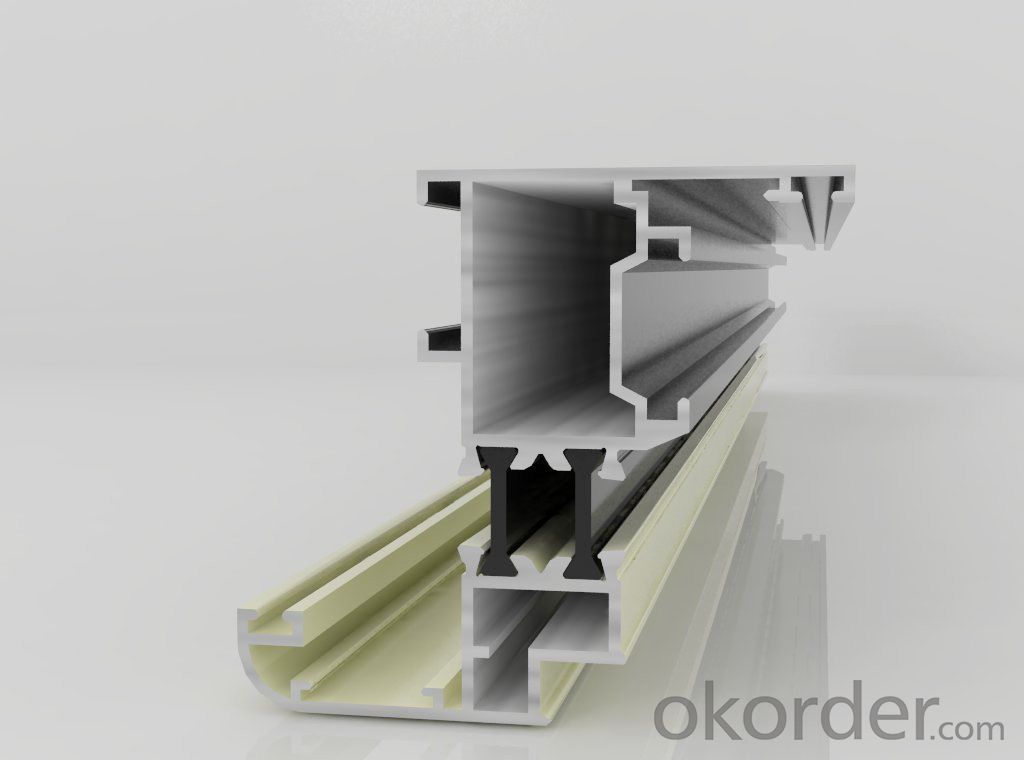

3.Aluminium Profile for Cars Auto-parts Good Quality Images:

4.Aluminium Profile for Cars Auto-parts Good Quality Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Can aluminum profiles be used in solar panel installations?

- Yes, aluminum profiles can be used in solar panel installations. Aluminum is a lightweight and durable material that is commonly used in the construction of solar panel frames. It offers excellent corrosion resistance and can withstand outdoor environmental conditions, making it suitable for long-term use in solar installations. Additionally, aluminum profiles can be easily fabricated and customized to fit specific panel sizes and mounting requirements.

- Q:Are aluminum profiles resistant to termites and insects?

- Aluminum profiles possess exceptional resistance against termites and insects, unlike wood that is vulnerable to termite infestations and insect harm. Being a nonporous substance, aluminum fails to offer nourishment to these bothersome creatures. Moreover, aluminum profiles are commonly shielded with safeguarding finishes such as powder coating or anodizing, reinforcing their resistance to termites and insects. Consequently, aluminum profiles emerge as a robust and enduring alternative for a wide range of applications, including window frames, door frames, and other construction endeavors where the menace of termite or insect damage lingers.

- Q:Do aluminum profiles require any special tools or equipment for installation?

- Yes, aluminum profiles typically require specific tools and equipment for installation. These may include a miter saw or aluminum cutting saw, drill press or power drill, measuring tools, screwdrivers, clamps, and fasteners specific to aluminum profiles. Additionally, certain installations may require specialized equipment such as a router or end milling machine for precision cuts and shaping.

- Q:Are aluminum profiles suitable for high-traffic areas?

- Yes, aluminum profiles are suitable for high-traffic areas. Aluminum is known for its durability, strength, and resistance to corrosion. These characteristics make it an excellent choice for areas with high footfall, such as shopping centers, airports, and train stations. Aluminum profiles are designed to withstand heavy loads, impacts, and frequent use, making them highly reliable in high-traffic environments. Additionally, aluminum profiles can be customized to meet specific requirements, ensuring they can withstand the demands of any busy area. In terms of maintenance, aluminum profiles are easy to clean and maintain. They do not require frequent painting or coating, saving time and resources. Moreover, aluminum is a sustainable and recyclable material, making it an environmentally friendly choice for high-traffic areas. Overall, aluminum profiles offer a combination of strength, durability, and low maintenance requirements, making them highly suitable for high-traffic areas.

- Q:How do I install aluminum profiles?

- To install aluminum profiles, follow these steps: 1. Start by measuring and marking the desired location where you want to install the aluminum profile. Ensure that the surface is clean and free of any debris. 2. Cut the aluminum profile to the required length using a saw or a miter saw. Make sure the cut is precise and smooth. 3. Use a drill to create pilot holes at regular intervals along the marked installation area. These holes will serve as the anchor points for the screws or bolts that will secure the aluminum profile in place. 4. Attach the aluminum profile to the surface by aligning the pilot holes with the corresponding holes on the profile. Insert screws or bolts through the holes and tighten them using a screwdriver or a socket wrench. 5. If you are installing multiple aluminum profiles, repeat the process for each section, ensuring that they are aligned and securely fastened to the surface. 6. Once all the profiles are installed, check for any gaps or unevenness. If necessary, adjust and tighten the screws or bolts to ensure a snug fit. 7. Finally, clean the installed aluminum profiles with a mild cleaning solution and a soft cloth to remove any dirt or residue. Remember to wear appropriate safety gear, such as gloves and safety glasses, while handling tools and materials during the installation process.

- Q:Can aluminum profiles be used in the manufacturing of furniture?

- Yes, aluminum profiles can be used in the manufacturing of furniture. Aluminum is a versatile and lightweight material that offers several advantages for furniture production. It is highly durable, resistant to corrosion, and has a high strength-to-weight ratio. These properties make it suitable for various furniture applications, including chairs, tables, shelving units, and frames. Additionally, aluminum profiles can be easily customized, allowing for the creation of unique and modern designs. The use of aluminum in furniture manufacturing also contributes to sustainability, as it is a recyclable material. Overall, aluminum profiles provide designers and manufacturers with flexibility and durability, making them a popular choice in the furniture industry.

- Q:What are the differences between horizontal and vertical aluminum profiles?

- Horizontal vertical hanger in the middle on the head,Therefore, the horizontal number will affect the surface a little, and when you have to find non decorative surface hangingThe vertical head is better, a hanging point, just cut off

- Q:What's the difference between aluminum oxide and electrophoresis?

- Main features: 1 aluminum oxide) has strong abrasion resistance, weatherability and corrosion resistance. 2) can form a variety of colors on the surface of the substrate, the maximum for your requirements. 3) hardness, making it suitable for all kinds of buildings, industrial materials.Main features: 1 electrophoresis aluminum) has strong film hardness and strong impact resistance. 2) has very high adhesion of film, aging is not easy to fall off. 3) has better wear resistance, weather resistance and alkali resistance than aluminum oxide. 4) surface color is rich, beautiful, with a mirror like luster effect.Aluminum electrophoresis processing in oxidized aluminum on the basis of better quality than the oxidized aluminum chip. The price is a little better.

- Q:Are aluminum profiles suitable for automotive racks and carriers?

- Aluminum profiles, indeed, possess the appropriateness for automotive racks and carriers. Being both lightweight and robust, aluminum emerges as an optimal material for instances that prioritize weight reduction, such as automotive racks and carriers. The adaptability and flexibility of aluminum profiles enable their design and engineering to cater to specific requirements, facilitating customization. Besides, aluminum's resistance to corrosion guarantees the endurance and long-lasting nature of automotive racks and carriers, even in unfavorable weather conditions. Moreover, the notable strength-to-weight ratio of this material contributes to an enhanced fuel efficiency and reduced emissions. In summary, aluminum profiles furnish a dependable and efficient resolution for automotive racks and carriers.

- Q:Aluminum profile spraying process

- Powder coating construction technology and requirements of the powder electrostatic spraying is the use of the principle of high voltage electrostatic corona electric field. With high-voltage anode in the gun head on the metal guide, is formed by spraying electrode of the workpiece, the formation of a strong electrostatic field between the gun and the workpiece. When the compressed air as carrier gas, powder coating from guide rod for powder barrels by powder pipe to spray gun, the corona discharge guide rod is connected with the high voltage anode is generated, and the negative charge density in the vicinity of the powder, with a negative charge, and entered into the field of electrostatic field strength is very high, in the dual role of static electricity and gas. The powder evenly ground to powder layer formed on the surface of workpiece thickness uniformity, and heat curing into durable coating coating construction process:

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Profile for Cars Auto-parts Good Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords