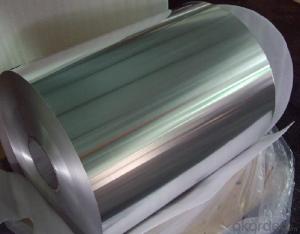

Aluminium Hot Rolled Foil With Best Price In Our Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

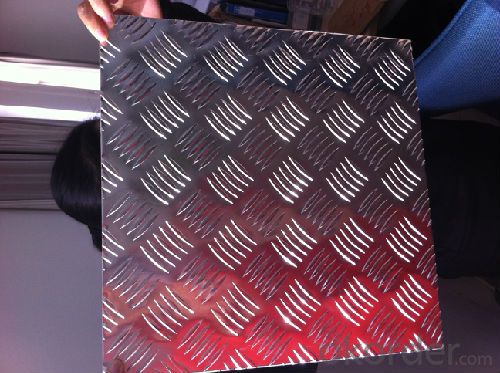

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 5 tons/each size.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q:my sis needs to know how to season her new stainless cookware is there anything she should do?

- I like Quaker High Fiber Oatmeal, the box that comes with 8 individual oatmeal packetsMaple brown sugar and cinnamon are my favorite flavorsIt tastes really good and is packed with tons of fiberBowel movements become irregular because your colon takes on too much waterFiber helps because the texture is gel like as it passes through your intestines and it helps prevent hard and dry stools that are a pain in the too passIf you eat a lot of high fat foods like meat, eggs, and cheese, then you are more likely to have slow and sluggish bowel movements, while fiber helps keep things regular.

- Q:im trying to make a bird for a project or anything out of aluminum foil , i just wanna know how to make it harder and stiff .

- So that terrorists could pass their plastic explosives through metal detectors at the airport.

- Q:I have to try to keep this small box as cold as I canI can use Aluminum Foil, 1 clear plastic sheet, Any colored construction paper, 1 sheet of tinted plastic, and newspaper.

- Consider wrapping the box in aluminum foil to reflect the coldnessThen wrap the whole thing in construction paperHowever, ur box still wouldn't be very coldIf I were you, I would dunk the box in liquid nitrogen.

- Q:IF A PIZZA IS A CIRCLE WHY DOES IT COME IN A SQUARE BOX

- Honey Roasted Cashews Makes 12 ounces 2 tablespoons honey 1/4 teaspoon cinnamon 1 tablespoon melted butter 1 (12-ounce) can salted cashews 1 In a bowl, combine honey, cinnamon and melted butterAdd cashews, and toss to coatSpread on a jelly roll pan 2 Bake in preheated 325-degree oven for 10 to 12 minutes, stirring at least onceCool to room temperaturecccccccccccccccccccccccccccccccccccccc Honey Roasted Cashews You can double or triple the recipe! SERVES 8 , 1/4 cups Ingredients 6 tablespoons liquid honey (1/4 cup plus 2 tablespoons) 2 cups unsalted dry-roasted cashews 1 1/2 teaspoons salt (can use less salt) Directions 1 Set oven to 350 degrees 2 In a heavy skillet over low heat, add in honey stir until warmed 3 Add in nuts and salt; toss thoroughly 4 Transfer to a baking sheet and bake for about 10-12 minutes, or until the nuts are a slightly darker shade of brown and the honey is almost hardened 5 Allow to cool then store in an airtight containercccccccccccccccccccccccccccccccccccccc.

- Q:How many fluoride ions are in 1.46 mol of aluminum fluoride?I calculated the problem already: 1.46 mol AlF3 6.02 x 10^23 formula units AlF3 3 ion F-The answer I got was 2.63676 x10^24However, my teacher asked me to put it in sig figs.Should I round the answer up to 3 x10^24 or should it be 2.64 x10^24 ?I'm really confused on this one so please helpThank you! :)

- Your answer should have 3 significant figures, because the problem gave you 3 to begin with (1.46 moles)So, if you did your calculations correctly, the answer should be 2.64 x 10^24.

- Q:I Need 10 Pure Substances, 10 Mechanical Mixtures, And 10 MixturesAll Household ItemsAny Ideas?

- There are three main approaches to managing a home improvement project: hiring a general contractor, directly hiring specialized contractors, or doing the work oneselfTo get more information visit at low country digs.

- Q:What can you make with it?

- you can make a bomb with 2 and 1/2 cup shredded aluminum foil, and 1 cup of works toilet bowl cleanerassuming it is the can with a screw on lid.It is a federal law that stats it is illegal to do this tho.

- Q:Anyone had much success with those metal boxes that you put wood chips into? Do they really flavor the food or are they just kinda OK not really?I'm thinking I'm not getting much flavor out of my gas grill and I'm thinking of buying an old-fashioned charcoal BBQ.If I go for the charcoal BBQ, anybody bought natural briquets? Are they available on line only or do major stores have them? I've heard so much about toxinogens then and toxo that when you burn the regular ol' instant hot briquets.

- Hello Querious: You can get wood chips at just about any store that sells briquetsSoak them for an hour in water, then wrap in aluminum foilToss on the flame of your gas grille, and they should start smoking within a few minutes If you really hate the gas, you can convert your grille with a disposable heavy aluminum foil pan that are used for Thanksgiving turkeysThe self-lighting briquets from a known seller are safeThey are just hardwood sawdust cooked without air and compressedThe petroleum products are off-putting, try an electric igniter or crumbled newspaper instead.

- Q:During a storm, I had a 10-foot corner post come off of our aluminum sidingIt looks like it had just been duct-taped at the top, and it's a bit of a mystery how it could have originally come outIn any case, it was incredibly difficult to find someone who wanted to find a solution that didn't include taking off a lot of siding - compounded by being such a relatively small jobFinally, yesterday, I convinced a siding guy to spend an hour forcing it back into place, then caulking it at the topHe added that it could come out again, however, so he strongly recommended securing it by nailing right through the siding at an angle, hopefully catching the inside of the corner(Apologies for not knowing the terminology.) Given that this is a makeshift solution, does this sound right, and are there any issues to consider when it comes to which nails to use, etc.? Many thanks-

- It is unfathomable to me why this siding guy didn't nail the damned thing himself I generally use screws when working around things like this, as one slip off the nail head and the hammer will leave a nice big dent in the aluminum Also, you can get hex head galvanized screws that have rubber washers under the headThat way water won't leak past the fasteners and get behind the siding.

- Q:Also I am trying to find out if I had cu1 or cu2 in chemistry, should I put h2o in my equation because the reaction took place in water? Or should I leave it out?

- I don't understand you question.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Hot Rolled Foil With Best Price In Our Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords