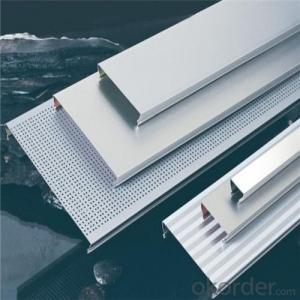

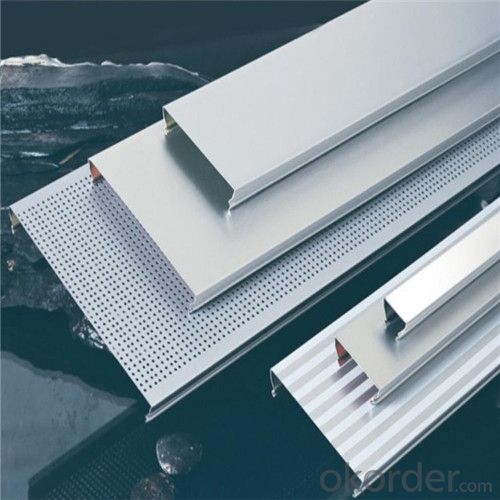

Aluminium Ceiling C-Shaped strip Panel with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

Designed and engineered to perform in multiple commercial environments under multiple stresses, cmax Metal Ceiling systems allow cutting-edge technologies to be applied to the most modern or traditional designs. Every component is designed and fabricated to exacting specifications and the highest manufacturing standards.

Size:

Ceiling Type | Size(mm) | Height(mm) | Thickness(mm) | Edge Type |

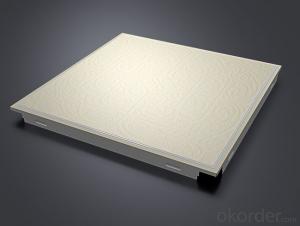

Clip In Ceiling | 300*300 | 18/20 | 0.45~0.56 | Beveled Edge/Square Edge |

600*600 | 20/24/28 | 0.45~0.7 | Beveled Edge/Square Edge | |

800*800 | 20/24/28 | 1.0 | Beveled Edge/Square Edge | |

300*1200 | 20/24/28 | 0.75~0.9 | Beveled Edge/Square Edge | |

600*1200 | 20/24/28 | 0.75~1.1 | Beveled Edge/Square Edge | |

Lay In Ceiling | 275*275 (295*295) | 8 | 0.60~0.70 | Square Edge |

575*575 (595*595) | 8/12/18 | 0.60~0.70 | Beveled Edge/Square Edge | |

585*585 (595*595) | 10 | 0.60~0.70 | Square Edge | |

585*585(605*605) | 10 | 0.60~0.70 | Square Edge | |

595*1195*575*1175 | 8 | 0.60~0.70 | Square Edge | |

603*1210*585*1195 | 8 | 0.60~0.70 | Square Edge | |

Ceiling Type | Open size(mm) | Width & Height(mm) | Thickness(mm) | Length(mm) |

Open Cell Ceiling | 50*50 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 |

75*75 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 1950 | |

100*100 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

125*125 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

150*150 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 1950 | |

200*200 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

Ceiling Type | Width(mm) | Length(mm) | Thickness(mm) | Edge Type |

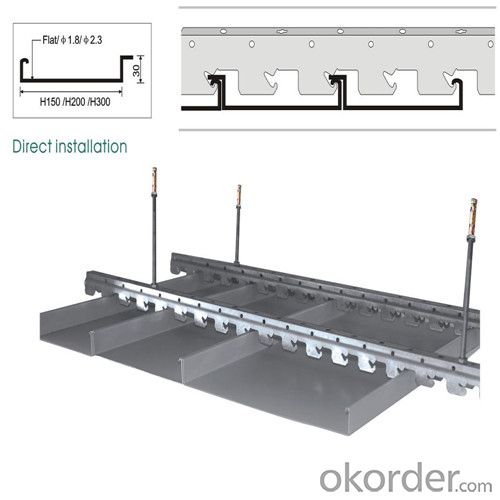

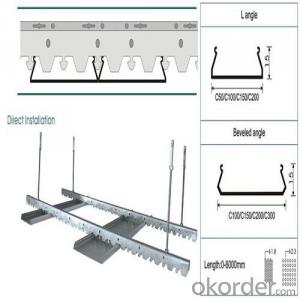

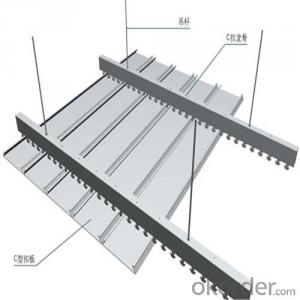

C-strip | C100/C150/C200/C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

S-strip | C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

H-strip | C150/C200/C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

G-strip | C100 | 1000~6000 | 0.45~0.85 | Square Edge |

Installation and Accessories

*Clip-in Concealed Metal Panel Ceiling

*Clip-In Panels are constructed of recycled aluminum

*Springs and clips are constructed of high performance steel

*Clip-In Panels integrate into and conceal 15/16” face HD/ID suspension grid

*Clip-In Panels for use in interior application

*Square edge design

*Standard sizes of 24” x 24”, 24” x 48” or custom size

*Clip-In Panels available in solid or perforated designs

*Clip-in placement allows for downward accessibility without special tools

*Easily incorporates air, fire, audio and other services

*Panels contain no organic compounds that support mold or microbial growth

*Factory applied, no-VOC powder coated paints and laminated finishes

The Lay in (I) system is easy to match grid system. The panels are right angle by 8mm chamfer. It's 100% upward accessible and installed on either silhouette grids or other 9/16" (15mm) exposed tee grids, forming unique overall effect. The silhouette grids also can offset manufacturing tolerance and installation tolerance. Also, it can be combined with mineral fiber panels to present a various installation effect.

Description:

1.Superposition joint part between main carrier and vice carrier or vice carrier and carrier is called point lap.

2.It uses lap structure to assembly, connection between joints dovetail very well. The joint face unknits and have a nice appearance.

3.There is a barb at the vice carrier joint, it can avoid loosing and falling from the infection of outside force.

4.Soleplate of main and vice carrier is zincification armor plate, which meets the national GB standard demand. We use baked paint zincifcation armor plate as baked paint panel,whoes capacity of zincification is high. It meet the national GB standard demand.

5. Raw Meterial is galvanized steel with 80-100g/sqm

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q:Kitchen aluminum plate inlaid with lights, lights do not change how to install how the equipment installed

- Aluminum slabs are the easiest to install in all lights! The aluminum gusset plate is stuck on the keel, with a small screwdriver (or small blade) from the aluminum buckle seam edge tilt a corner! Slowly pull down the lampshade by hand, with the same method in the next pull down a piece of buckle, see the lamp body is stuck in the keel above, a hand to pull the keel outward, the other hand to the top of the lamp , Light on the Kai down, and know how to unload the unloading to understand how installed, and installed this kind of lamp a pliers a small screwdriver to get!

- Q:How to distinguish between aluminum plate and what kind of board board

- The difference is that the surface coating is different, the lowest price of film, followed by rolling, and then the next nano. General home improvement, roller the most appropriate. If you pay attention to style with the general European-style idiots with nano-aluminum plate, modern with roller coated aluminum plate. Laminating has been useless, because easy to oxidize discoloration, according to your price on-demand purchase, personal opinion of the kind of high-end oxidation is not necessary, that is to cover a ugly, good clean fumes.

- Q:What are the precautions and corresponding regulations in the construction of aluminum slabs?

- Aluminum slab ceiling decoration quality requirements: The materials used for the ceiling (eg, the cover panel, the keel) must meet the national quality standards. The variety, style and specifications of the materials used for the ceiling must meet the design requirements. The mounting position of the keel must be correct and secure, and the keel should remain straight, without bending, without deformation. Mask version to maintain integrity, no Alice, delamination and other defects, the installation needs to be installed firmly. Hanging parts, connectors should meet the requirements of the product portfolio.

- Q:Aluminum veneer and aluminum buckle plate are what is the difference

- Aluminum veneer generally refers to the thickness of 1.5 mm 2.0 2.5 3.0 4 5mm ... ... aluminum alloy plate, you can ceiling, you can decorate the wall.

- Q:What is the difference between aluminum-plastic and aluminum-plated boards?

- Aluminum-plastic plate is 1.2 * 2.4 meters of double-layer decorative materials, mainly used in outdoor facade, but also useful in the interior to do background and shape. Aluminum plate is a piece of aluminum, mainly used in the kitchen and bathroom ceiling.

- Q:What is the integrated ceiling, aluminum slab ceiling than pvc ceiling which advantages, integrated ceiling which big brand, what are the top ten brands?

- Integrated ceiling (also known as the overall ceiling, combination ceiling, intelligent ceiling) Following the overall bathroom and the overall kitchen after the kitchen and bathroom ceiling ceiling decoration of the latest products, it represents today's kitchen and toilet ceiling decoration of the top technology. Simply put, the integrated ceiling is the ceiling module and electrical modules, made of standard specifications can be modular modules, installed together when the installation.

- Q:If they say that the anti-oil strong nano-drawing does not change color in the end what is good? Please answer experts! Brushed the drawing of the nano is the nano of it

- Is the nano-wire plate is very cheap and practical general 100 quick money about one square meter

- Q:Home improvement integrated ceiling of the aluminum plate, film and roller coating where the difference? Look detailed, thank you ~!

- The surface treatment process is not the same as the film length of the film will be lighter

- Q:Whether it is the bathroom or the ceiling between the kitchen now the most popular are aluminum plate (30x30 integrated ceiling), but in the eyes of professionals they are more pro-use gypsum board, which is why In fact, there is a little - anti-condensation. His heat conduction than the metal a lot, so there is no possibility of dripping the kitchen

- Is the designer a designer or a decoration worker? Buy an integrated ceiling. Not only save time and save money. Gypsum board fee is time consuming. Buy a little aluminum plate (oxidation), not only will not change color, and very good care (said to be able to use 50 years). Half a day to install it.

- Q:The company is to do the aluminum alloy ceiling, is the first to buy aluminum back to the factory, do the shape, and then take the outside to spray the surface of the oil. Aluminum is how much money to buy back a ton, on the outside called someone else processing fuel injection Is how much money a square as we count, we sold to the customer is the number of a square to count, I ask this, how do I calculate the cost of it? Our company's product cost is not what is the kind, is based on the requirements of customers to do.

- And then can be collected into the cost of manufacturing costs allocated to the comprehensive calculation of the cost.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Ceiling C-Shaped strip Panel with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords