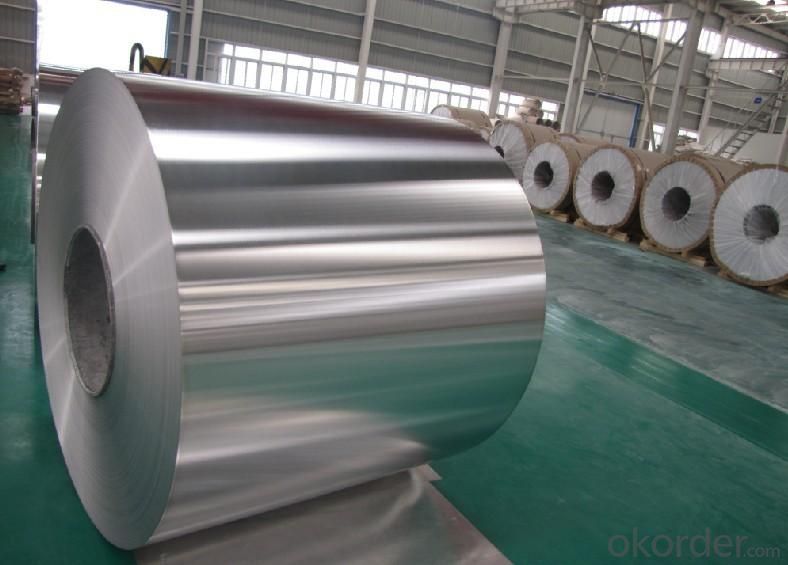

Color Coated Aluminum Coil Aluminum Alloy

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Color Coated Aluminum Coil Aluminum Alloy

1. Grade

| Series: | 1100 etc. |

| Series: | 3003 3004 3005 etc. |

| Series: | 5006, 5052 |

| Series: | 8011 etc. |

2. Thickness

| Plate Thickness | 0.1mm, 0.12mm,0.15mm,0.20mm,0.25mm,0.28mm,0.3mm,0.35mm,0.38mm, 0.4mm,0.5mm, 0.53mm, 0.58mm,0.68mm,0.7omm,0.73mm,0.75mm, 0.90mm, 1mm, 1.2mm |

| Coil Thickness | 0.1mm, 0.12mm,0.15mm,0.20mm,0.25mm,0.28mm,0.3mm,0.35mm,0.38mm, 0.4mm,0.5mm, 0.53mm, 0.58mm,0.68mm,0.7omm,0.73mm,0.75mm, 0.90mm, 1mm, 1.2mm |

3. Description

Alloy | AA1100, 3003, 3004, 3105, 5006, 5052, 8011, etc , etc. |

Temper | H16, H18, H24, H26, H28 |

Thickness | From 0.1mm to 1.2mm |

Width | Standard width:1240mm, 1270MM |

Special width:1000mm, 1200mm, 1240mm, 1270mm, 1520mm, 1620mm | |

Diameter | Standard dia:1200mm |

Interior dia: 150mm,405mm, 500mm, 505mm, 510mm | |

outer diameter: 1200mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating thickness | PE:>=16 micron , PVDF:>=25 micron |

Protective film | As per customer’s request |

Coating paint | PVDF, PE(Polyester), epoxy, polyamide, polyurethane |

Color | Soid, metallic, high gloss,stone,timber,brush,mirror,sparkling, RAL or by customer requirements. |

Weight | As per customer’s request |

| Surface | Embossed, mill finish, coated |

| Gloss | 10-100% |

| Coating Hardness (pencil resistance) | More than 2h |

| Coating adhesion | 1J |

| Impact Resistance | No peeling or cracking(50 kg/cm) |

| Application | ACP,wall cladding,facades,roofs and canopies,ceilings,signboards,blind window,display platforms,electrical panels,etc |

| Coating Thickness | PE coating:more than 16 micron |

| PVDF coating:more than 25micron |

4. FAQ

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q:Kitchen wall paste tile master only posted 2.2 meters high, he went back home. I would like to do stacked ceiling, do not know 300 * 300 aluminum buckle plate can do stacking ceiling? Thank you!

- Usually called the level of ceiling, or a secondary ceiling.

- Q:Figure, 600 * 600 or 300 * 300 aluminum buckle plate can not make such a light groove, the edge is not used to close the edge of the edge? Not much, thanks for the answer!

- If you really want to use aluminum buckle board, you can try to use matt aluminum slab.

- Q:Restaurants with aluminum cords hanging ceiling of the small households, if your kitchen and restaurants are linked together, to unify the use of an effect is also not a bad idea. It is very convenient to use aluminum plate hanging ceiling maintenance, waterproof performance is also very good.

- Restaurants with aluminum cords hanging ceiling of the small households, if your kitchen and restaurants are linked together, to unify the use of an effect is also not a bad idea. It is very convenient to use aluminum plate hanging ceiling maintenance, waterproof performance is also very good.

- Q:How to sub-aluminum buckle plate is good or bad?

- Look at the keel: keel is good or bad is a lot of consumers ignore the problem, the keel material is generally divided into aluminum, iron and no fingerprint steel. Aluminum keel will not rust, but because the cost is relatively high sales so very little. Iron keel is easy to rust, although the keel section hidden in the back of the ceiling generally do not see, but the rust scattered on the ceiling on the ceiling is not good, over time will affect the stability of the ceiling. No fingerprint steel keel relative to the iron keel it is not so easy to rust, is currently the most commonly used home improvement tooling sales. I sincerely hope that consumers can buy their own ideal integrated ceiling products.

- Q:Kitchen bathroom with aluminum slab plate can do shaped ceiling?

- Bad to do, aluminum buckle plate is surrounded by a buckle fixed, to do modeling or with other plates, such as aluminum-plastic plate,

- Q:Home kitchen ceiling, master less card a piece of aluminum plate, said tomorrow to give me a piece of cards, I do not know how to card up?

- That good card, on the buckle up on the line friends

- Q:Aluminum plate: a decoration of the board with the plate, aluminum, not plastic!

- With a small point of kerosene dripping up, wipe it on it

- Q:Is the aluminum slab ceiling applicable to the corridor?

- The general size of the corridor can not use a few pieces are complete aluminum plate, if there is not part of the whole piece, it is not beautiful. Not recommended.

- Q:Integrated ceiling aluminum slab plate for you

- Good change, but it is best to find a master for you to change the middle of the good change, but to the edge, and the pillars, the need to cut the plate, this is more trouble.

- Q:How to remove the ceiling of the aluminum plate

- First prepare a word screwdriver With a screwdriver with the board and the board will be a piece of force to pry down There is one of you to buy a glaze top suction, forced a suction down

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Coated Aluminum Coil Aluminum Alloy

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords