Aluminum Ceiling Panel for Easy Installation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

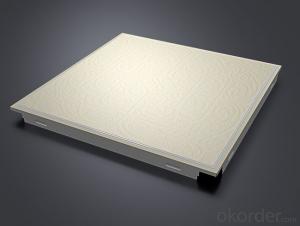

Product: Aluminum Ceiling

Material: Aluminum Sheet

Thickness: 0.5-0.8mm

System: Metric or British System

Edge: Clip in, Lay in, Lay on

Edge height: 8mm, 10mm, 18mm

Surface Finish: Powder coating, Pre-paint; Plain or Perforated (1.8mm, 2.3mm)

Function: Fireproof, Heat Insulation, Moisture-Proof, Sound-Absorbing, Waterproof

EASY PLENUM ACCESS: The panels can be easily demounted by hand allowing easy and full access to services and installation in the plenum.

DESIGN FLEXIBILITY: Aluminum ceiling panel appearance provides interesting possibilities for spatial room designing. The ceiling panel show different style pattern and shape, which engage you match your design.A range of colors and finishes is standard available and special colors upon request.

PRODUCT CHARACTERISTIC: 1) Surface smoothness and easy cleaning; 2) Flexible suspension system makes each ceiling tile easily installed and disconnected; 3) Easy to match lamps or other ceiling parts; 4) Surface color can be stable for 10 years by indoor use; 5) Function: Acoustical, Fireproof, Waterproof, Washable, Light reflect.

- Q:Kitchen bathroom ceiling with aluminum plate how much thickness of the appropriate, the full price of how much?

- It is best to use 0.8 of the aluminum plate hanging ceiling is appropriate, the price depends on what brand. Generally about 80-120 yuan.

- Q:Aluminum cords and keel with the proportion of how much

- To commonly used 300 * 300 aluminum slab plate, for example, the corner to the whole piece, the number of sheets * 300, plus the top three sides of the ceiling is the amount of keel

- Q:Aluminum plate next to the edge of the edge, to wear a hole, put a small pipe down. What kind of drilling is good? Edge and aluminum plate are already installed up.

- Unloaded, cut a hole on the line, simple

- Q:Kitchen and bathroom ceiling aluminum plate coated, oxidation and mirror what is the difference

- The year of the film is easy to change color. And because it is posted a layer of film up, it is the thickness of the actual thinner aluminum. But it can be done more. Oxidation plate of course the material is better, at least antioxidant capacity to increase a lot. More durable. Mirror panel looks smoother,

- Q:Figure, 600 * 600 or 300 * 300 aluminum buckle plate can not make such a light groove, the edge is not used to close the edge of the edge? Not much, thanks for the answer!

- Side of the edge is no problem, but the aluminum plate to do this, may not be good-looking, there are two main, one is added after the light of the aluminum plate will be bright light, the second is the same as the aluminum plate will reflect the light Tube or a long time gray, ugly.

- Q:Metal ceilings, including aluminum slabs and so on

- Now gypsum board, mineral wool board is also constantly improving, there are waterproof gypsum board and sound-absorbing mineral wool board. But they are single plate, not easy to scrub, for the development of the keel keel, and more for the project. PVC products, poor oxidation resistance, no moisture, no fire, easy to deformation, discoloration, and more for the old ordinary home improvement. With the improvement of the quality requirements of the decoration, and now the home decoration has been basically used to do aluminum ceiling plate ceiling.

- Q:Aluminum slab plate ceiling is not without light steel keel

- Not the gypsum board when used with light steel keel, they are keel, but not a model specifications and types.

- Q:Do you need to buy expensive?

- As long as it is a molding. Not posted the pattern of the line. You buy the cheapest I promise as long as no earthquake you do not change this life you do not have to worry about it bad friends

- Q:The kitchen lights in my house are broken! Ceiling lights are with the buckle board together, do not know where to start out, I would like to ask you how to get big? Need tool not? Thank you! anxious

- If it is the side of the aluminum plate, it is very simple, with a pass through the sewer of the child (chuāi zi) suction ceiling lamp near the center of the buckle, pull down, you can put that buckle off, If the plate there is a side of the keel caught in the folder sandwiched, to reach out and press the side there, in short, to close the buckle that off. The next step, reach out, the ceiling of the gongs are clamped by the keel of the two sides press down, you can put the ceiling of the buckle plate unloaded, for a good light after the buckle up as the original ok.

- Q:How to buy aluminum buckle board can save money

- (1) to view its aluminum thickness. The thickness should not be less than 0.6 mm, or likely to cause the phenomenon of collapsed waist. When choosing to pay attention to whether the business through the thickening of the paint layer to increase the overall thickness, this aluminum plate do not buy. (2) to check the true quality of the material to prevent illegal manufacturers of stainless steel fake aluminum, nine is home to remind the pure aluminum or impure aluminum or stainless steel iron, you can use the magnet to verify that pure aluminum does not smoke Magnetic, and the quality of aluminum or false aluminum can absorb magnetic. (3) to identify the aluminum plate in addition to pay attention to the surface finish, but also to observe the thickness of the board is uniform, whether double-sided paint, pinch the board feel, flexibility and toughness is good enough.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Ceiling Panel for Easy Installation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords