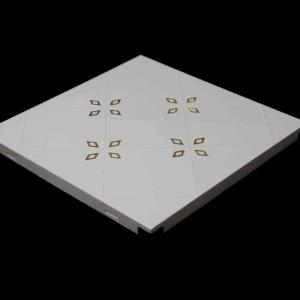

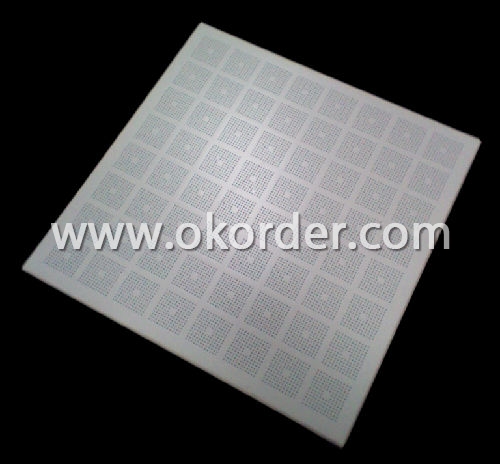

High Quality Aluminum Ceiling Sheet Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1X20'FCL m²

- Supply Capability:

- 3000 M2 Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Aluminum ceiling

1.Material: aluminium sheet

2.Size:600*600, 605*605, 100*100, 400*400, 500*500, 100*600, 150*150, 150*800

800*800, 300*300, 300*1200, 300*600, 600*1200

thickness from 0.45MM to 0.7MM

3.Colour: white,silver,any of the RAL colour,etc.

4.Edge:Lay in, Lay out and Clip in

Personality of Aluminum ceiling

1. tidy, clean and easy to clean and install

2.green and long time for qulity gurantee

Application of Aluminum ceiling

1.Fasle ceiling in Airport, Station, High-grade building

2.Washing room and kitchen etc.

Package of Aluminum Ceiling

1.Standard export package, film inside carton outside

2.16 or 20 pcs in one carton

Installation instruction of Aluminum Ceiling

1. for square board

A.Firstly lift up the light keel and keep them at the same height and level

B:Enter the trangle card into the trangle keel, then according to the definite distance, put the triangle hanger into the light keel.

C:After finishing the installment of keel, press the clip-in square ceiling tiles into the slot of triangle keel(remark: the direction of folder with small hole is to insert into the slot of triangle keel)

D:Folding the edge which has no hole to connect the plate one by one, using the angle gap to install the plate and press a little on the plate, then it wil achive a better effect.

2.for c shaped strip ceiling

A:installing the wall angle at the same height

B:Arranging the hanging pole in a row and using hanger to connect the hanging pole with the keel, adjusting the height and flatness to the suitable position.

C:Pressing the two parallel edges into the triangle keel slot and making sure they are vertical mutually, then installing the rest plates.

D:Pressing a little on the plate when connecting the plates one by one, it will attain more better effect.

E:After the installment finished, then tear off the protective film covered on the aluminum plate.

F:Wearing gloves when installing plates, if you remain finerprint or stains on the plates, please remove it off with the boiled wter and detergent, and then dry it.

3.for curtain ceiling

A:As the open ceiling, it is necessary to brush the internal of the ceiling into back.

B:Fixing the expansion bolts into the ceiling then hanging the hooks or main keel onto the bolts

C.Put the curtain ceiling into the gap of the keels.

Production Line

We have 4 production line, 20 containers per month.

Our product combine quality with best price, there is a big professional team after the product.we are your best choice, we are waiting for your call.

- Q:Aluminum slab plate ceiling by the extension of how to calculate the meter

- The length of each wall is added, as you mentioned 9m * 3m room, 9m long, wide 3m.

- Q:Aluminum plate next to the edge of the edge, to wear a hole, put a small pipe down. What kind of drilling is good? Edge and aluminum plate are already installed up.

- In general, with a large scissors to get, do not need a very professional tool After the tube was passed, it would be better to hit the seal around the hole

- Q:Integrated ceiling aluminum slab plate production process?

- Into the raw material aluminum plate → whole roll aluminum surface cleaning, degreasing → according to the different process of oxidation tank anodizing or roller coating or brush plastic peritoneum or more complex process → surface paste protective film → plate for the initial segmentation, cut into open material size → open Material size of the plate to stamping, the first angle, and then out of the edge and buckle plate material processing is the highest technical content, followed by the stamping of the same big no big name

- Q:How about the quality of the ceiling

- The second generation of PVC is the first generation of the product.

- Q:What are the properties of aluminum?

- Aluminum reflection of the light is also very good, reflective UV than silver, aluminum more pure, the better the ability to reflect, it is often used to create high-quality mirrors, such as solar cookers and so on.

- Q:Is the living room suitable for aluminum slabs?

- As long as good-looking, environmental protection, with nothing material rules If you are home, do not recommend the living room to do Lvkou Ban, because one will reduce the high level, the second is a large area of aluminum slab board stiffness is not good, the wind has ups and downs. With gypsum board to do a few light pool, divided into several functional grid (dining area, rest area, etc.) just fine. Of course, if your living room height is big enough, another matter.

- Q:Aluminum Clamps Lamps 450x450

- The specifications of the lamps can be selected according to the specifications of the aluminum gusset. Generally 300 * 300,300 * 600,300 * 450 and so on. Aluminum slab plate installation method: the general buckle with a dedicated keel, keel for galvanized steel and paint steel, the standard length: 3000MM.

- Q:Want to do aluminum ceiling production, do not know what sets of production equipment. What is the price of the equipment?

- Aluminum ceiling equipment is divided into two types: one is a molding, just a machine and a set of molds that processing aluminum ceiling; the second is the second molding, you need two machines and two sets of mold with the completion. But quite for new customers, more people choose the second molding, because it mature and stable, scrap rate is almost zero. Foshan Hua is your good choice.

- Q:The first question: what are their keel ceiling, the other used keel has no features? The second question: how are their installation methods and their keel spacing? Is there any special spacing? The third question: I hope you can provide photos of the above two questions, thank you for additional points.

- "Steel plate" - this is not plastic buckle plate? It may be customary on the difference between the name of it - if it is plastic buckle plate, then it is the main keel keel, the installation of the time with the self-tapping screws to the plastic buckle plate can be fixed on the wooden keel. Film ceiling, should be "soft film ceiling", which has a special accessories production, can not be called keel.

- Q:Most of their prices include installation fees, right? Is there a price of tens of dollars now? Less than 100 yuan per level are false, right? thank you all

- No, aluminum buckle is one of the integrated ceiling.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 9 Million |

| Main Markets | South America 8.82 Eastern Europe24.26 Africa 11.03 Mid East 45.75 Eastern Asia 10 |

| Company Certifications | CE CERTIFICATE |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Foshan |

| Export Percentage | 80% - 90% |

| No.of Employees in Trade Department | 500-1000 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | 53,000 square meters |

| No. of Production Lines | 13 LINES |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

High Quality Aluminum Ceiling Sheet Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1X20'FCL m²

- Supply Capability:

- 3000 M2 Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords