Aluminium Metal Ceiling Panels,C-Strip Type

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

Designed and engineered to perform in multiple commercial environments under multiple stresses, cmax Metal Ceiling systems allow cutting-edge technologies to be applied to the most modern or traditional designs. Every component is designed and fabricated to exacting specifications and the highest manufacturing standards.

Ceiling Type | Size(mm) | Height(mm) | Thickness(mm) | Edge Type |

Clip In Ceiling | 300*300 | 18/20 | 0.45~0.56 | Beveled Edge/Square Edge |

600*600 | 20/24/28 | 0.45~0.7 | Beveled Edge/Square Edge | |

800*800 | 20/24/28 | 1.0 | Beveled Edge/Square Edge | |

300*1200 | 20/24/28 | 0.75~0.9 | Beveled Edge/Square Edge | |

600*1200 | 20/24/28 | 0.75~1.1 | Beveled Edge/Square Edge | |

Lay In Ceiling | 275*275 (295*295) | 8 | 0.60~0.70 | Square Edge |

575*575 (595*595) | 8/12/18 | 0.60~0.70 | Beveled Edge/Square Edge | |

585*585 (595*595) | 10 | 0.60~0.70 | Square Edge | |

585*585(605*605) | 10 | 0.60~0.70 | Square Edge | |

595*1195*575*1175 | 8 | 0.60~0.70 | Square Edge | |

603*1210*585*1195 | 8 | 0.60~0.70 | Square Edge | |

Ceiling Type | Open size(mm) | Width & Height(mm) | Thickness(mm) | Length(mm) |

Open Cell Ceiling | 50*50 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 |

75*75 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 1950 | |

100*100 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

125*125 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

150*150 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 1950 | |

200*200 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

Ceiling Type | Width(mm) | Length(mm) | Thickness(mm) | Edge Type |

C-strip | C100/C150/C200/C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

S-strip | C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

H-strip | C150/C200/C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

G-strip | C100 | 1000~6000 | 0.45~0.85 | Square Edge |

Detailed product description:

1) Item: W-35, 38 main channal, L angle, Connor Bead, DC-60, U-60, 50 Stud & track, 75 Stud and track, 100 Stud and track, ect.

2) thickness: 0.4-1.0mm

3) Length: 3000mm or dependes on customer's request

4) Zinc coating: 50-220g/m2 (depends on the customer's request)

5) Size as fellow form: (Width*Height*Thickness)

Product apply in: Mid East , Rusia, Europ, South America, Africa

Certificate for products:CE,stand :EN13964; ISO9001-2000

Instructions:

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the keels' vertical points and intensity.

(4) The metal stud with hole : one of our product is the special hole on C-stud every 600mm, which is easy for workers to install the electric lines and water tubes.

(5) Various sizes of metal track and metal stud : we are able to manufacture German,

(6) Factory direct sale price : We have our own factory to produce raw materials----galvanized(zinc coated) steel, as well as the product line, so we can provide you a lowest price.

Installation and Accessories

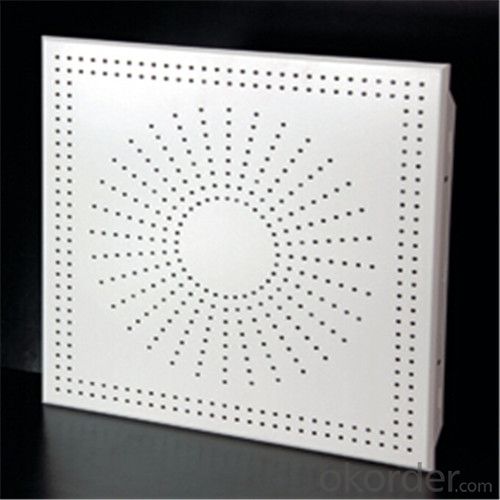

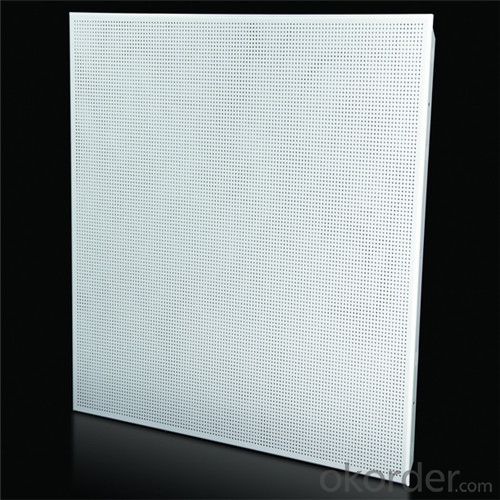

Clip-in Concealed Metal Panel Ceiling

*Clip-In Panels are constructed of recycled aluminum

*Springs and clips are constructed of high performance steel

*Clip-In Panels integrate into and conceal 15/16” face HD/ID suspension grid

*Clip-In Panels for use in interior application

*Square edge design

*Standard sizes of 24” x 24”, 24” x 48” or custom size

*Clip-In Panels available in solid or perforated designs

*Clip-in placement allows for downward accessibility without special tools

*Easily incorporates air, fire, audio and other services

*Panels contain no organic compounds that support mold or microbial growth

*Factory applied, no-VOC powder coated paints and laminated finishes

The Lay in (I) system is easy to match grid system. The panels are right angle by 8mm chamfer. It's 100% upward accessible and installed on either silhouette grids or other 9/16" (15mm) exposed tee grids, forming unique overall effect. The silhouette grids also can offset manufacturing tolerance and installation tolerance. Also, it can be combined with mineral fiber panels to present a various installation effect.

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q:0.6 mm aluminum buckle plate is multiple

- Equal to 12.2 kg weight of a board.

- Q:What is the difference between mineral wool board and aluminum ceiling?

- Aluminum slabs are usually used in home improvement market. Because it is generally used in the kitchen bathroom, when used the most important concern is the effect of oil and water. Aluminum plate, especially the roller coating of the durability of the protective effect is better Mineral wool sheet is mainly used in the engineering market. Such as offices, large public places. This kind of place is relatively important for the fire function. For this aspect more value. The use of different categories, according to the specific purpose of use to choose.

- Q:Aluminum plate and rock wool color plate which attracts the effect is good

- Because the rock wool color steel rock wool can play a sound-absorbing effect.

- Q:What is the brushed aluminum plate

- Aluminum plate is made of aluminum alloy plate, through the open material, shear angle, molded, aluminum plate surface using a variety of different coating processing to get a variety of aluminum plate products, aluminum slab plate, the most important two Type, one is home improvement integrated Lvkou Ban, the other is the engineering Lvkou Ban, home-made aluminum slab board mainly to roll and frost the main series of two, with the development of home improvement integrated aluminum plate has been Variety of different processing technology are used to them, such as thermal transfer, glazed, ink printing, mirror, 3D and so on series is the most popular in recent years, home improvement integrated aluminum slab plate, home improvement integrated aluminum plate is Board surface fancy, service life, board advantage and so on to obtain market recognition, engineering aluminum slab board is commonly used roller coating, powder coating, film, scrub and other surface coating, the surface is relatively simple, the color is solid , Of which milky white is the most expensive to use aluminum slab plate, engineering aluminum plate to buy the most important depends on the coating, coating color protection is the primary consideration, the coating to maximize the life to ensure that the owners interest.

- Q:Hall ceiling is what material is better aluminum card board, gypsum board, or wood version?

- If the economic conditions allow you to consider the film, the future in the kitchen, bathroom and so easy to scrub, and for a long time will not change color.

- Q:What kind of light is the kitchen? Can the old ceiling lamp be installed?

- Because the aluminum plate is directly buckle in the keel of the gap, if too heavy, then a long time by gravity, and so on to fall off. But as many will be out, this has not done the experiment, not clear, but according to the general buckle buckle degree, the kind of no more than 500g of the ceiling should be no problem.

- Q:Will the kitchen and bathroom with 300 * 300 of the aluminum plate, the following size of the embedded kitchen and toilet lights and ceiling can choose?

- Hello there! I suggest you can call to buy the business to ask, do not blindly hands yourself, to avoid unnecessary danger! It is also troublesome to break up!

- Q:How to install the kitchen aluminum plate

- General buckle with a dedicated keel, keel for galvanized steel and paint steel, the standard length: 3000MM. The 1, according to the same level of height installed edge collection series. 2, according to the appropriate spacing hoisting light steel keel (38 or 50 keel), the general spacing of 1-1.2 meters, the distance from the provisions of light steel keel distribution. 3, the pre-installed in the buckle keel hanging pieces, together with the buckle keel close to the light steel keel and light steel keel in the vertical direction buckle in the light steel keel below the girdle keel spacing is generally 1 meter, all Bahrain must Adjust the level (in general, the vertical distance between the building and the aluminum plate to be lifted does not exceed 600MM, do not need the middle plus 38 keel or 50 keel, and the use of keel hanging pieces and plug directly connected). 4, the buckle in parallel with the order of parallel buckle in supporting the keel, the buckle board connection with a special keel series connection connection. 5, the board must be installed with gloves, such as accidentally leave fingerprints or stains can be washed with detergent after cleaning can be dry, a good installation process easy to disassemble.

- Q:What is the kind of aluminum slab ceiling? How can we see it simply?

- Focus on after-sales service Even if the quality of the material, we can not guarantee its long-term use in the permanent to maintain the perfect performance, without any problems, so we choose aluminum cords hanging ceiling material, as much as possible to select some of the larger brands , Clear its after-sales service, reduce the lives of future security risks, but also to our home life more secure.

- Q:What is the characteristic of the ceiling plate?

- Relative to the gypsum and fiber concrete plate, its weight is almost negligible, greatly reduce the construction workers labor intensity and construction load, and the scene only for assembly work, its product quality is not affected by the site environment, construction period is short, greatly improved working conditions. ??? Relative to the plastic buckle board, which does not change color is not aging, in the high temperature and humidity environment performance is better; can be repeatedly removable plastic buckle can not be the advantages of this.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Metal Ceiling Panels,C-Strip Type

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords