Alu-slab

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

1. Brief introduction

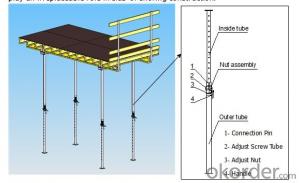

Especially for projects with a large number of similar applications and open facades, Alu-slab system is the right solution. The panel is end product, no assembling on site and it is easily to build, ease of application, more important thing is, the panel is light weight, a dead lift is achieved, save time and effort.

2. Competitive advantage

① Light weight but high load bearing capacity

The panels could be transported by manual work so that it greatly reduces the aggregate cost, accelerates the erection speed, and all in all increases the aggregate benefit.

②Quickly turnover of slab panels

The early dismantling prop system speed up the turnover of the panels, minimize the investment, lower the cost, improve the working efficiency, and shorten the project period under the precondition of keeping the concrete structure and safety uninfluenced, in line with the erection requirement and ensuring the project quality.

③Cost effective with early dismantling prop system.

This early dismantling system is simple, safe and fast, saving at least 50% percent of your construction time.

3. Applications

- Q:What are the common accessories used for connecting steel props to temporary structures?

- The common accessories used for connecting steel props to temporary structures include: 1. Prop heads: These are the top components of steel props that provide support to the structure. They are usually adjustable in height and can be easily connected to the prop shaft. 2. Prop pins: These are used to secure the prop heads to the prop shaft. They are inserted through the designated holes in the prop heads and shaft, ensuring a stable connection. 3. Prop nuts and bolts: These are used to tighten and secure the prop shafts in position. They provide additional stability to the temporary structure and prevent any accidental movement or collapse. 4. Prop sleeves: These are cylindrical components that are used to connect two prop shafts together. They slide over the overlapping portion of the shafts and are secured with nuts and bolts, providing a strong and stable connection. 5. Base plates: These are flat plates that are placed at the bottom of the steel props to distribute the load evenly and prevent sinking into the ground. They provide a stable foundation for the temporary structure. 6. Struts and bracing: These accessories are used to provide additional support and stability to the steel props. Struts are diagonal braces that are connected between the prop heads and the temporary structure, while bracing is used to connect multiple steel props together, reinforcing the overall structure. 7. Adjustable feet: These are used to level the steel props on uneven surfaces. They can be adjusted in height to ensure a stable and balanced structure. These common accessories play a crucial role in connecting steel props to temporary structures, ensuring their stability, safety, and functionality.

- Q:Can steel props be used for supporting slabs and beams?

- Yes, steel props can be used for supporting slabs and beams. Steel props, also known as adjustable props or construction props, are devices used in construction to support temporary structures like formwork, slabs, beams, and columns. They are made of steel and are adjustable in height, allowing them to be used in various applications. Steel props are designed to provide temporary support and stability to structures during construction or renovation projects. They can be used to support slabs and beams of different sizes and weights. The adjustable feature allows for easy installation and customization to specific project requirements. The main advantage of using steel props is their strength and load-bearing capacity. They are capable of supporting heavy loads and provide a stable platform for construction work. Additionally, steel props are durable and can withstand harsh conditions on construction sites. It is important to note that steel props should be used in accordance with the manufacturer's guidelines and engineering specifications. Proper installation and regular inspection are necessary to ensure the safety and stability of the supported structures.

- Q:Can steel props be used in the construction of offshore platforms or oil rigs?

- Yes, steel props can be used in the construction of offshore platforms or oil rigs. Steel props are commonly used in construction projects to support temporary structures, such as formwork or scaffolding. They are designed to provide vertical support and stability during construction activities. In the context of offshore platforms or oil rigs, steel props can be utilized during the construction phase to support various components, such as decks, modules, or equipment. They can help distribute the weight of these structures and ensure their stability in the harsh offshore environment. Steel props are preferred in offshore construction due to their high load-bearing capacity, durability, and resistance to corrosion. They are typically made of high-strength steel and are designed to withstand the challenging conditions present in offshore environments, including strong winds, rough seas, and corrosive saltwater. Furthermore, steel props can be easily adjusted and adapted to accommodate changes in the construction process or to provide additional support where needed. Their modular design allows for quick installation and removal, making them a practical choice for offshore construction projects that often require flexibility and efficiency. However, it is important to note that the use of steel props in offshore platforms or oil rigs is typically limited to the construction phase. Once the permanent structures are in place, the steel props are no longer required and are usually removed. The permanent structures are designed to provide the necessary support and stability for the operational phase of the offshore platform or oil rig.

- Q:Can steel props be adjusted to different heights?

- Indeed, different heights can be achieved by adjusting steel props. In construction, steel props, also referred to as telescopic props or adjustable props, are frequently employed to provide support for formwork or scaffolding. These props feature an inner tube and an outer tube, which can be extended or retracted to attain the desired height. Typically, the adjustment is accomplished by rotating a threaded collar or utilizing a pin system on the prop. As a result, steel props offer a versatile and convenient solution for diverse construction requirements, as they enable effortless and accurate height adjustments.

- Q:How do you ensure proper coordination between different trades when using steel props?

- Proper coordination between different trades when using steel props can be ensured through effective communication, regular meetings, and detailed planning. This includes sharing project schedules, specifications, and drawings with all relevant trades to ensure a clear understanding of their respective responsibilities and timelines. Additionally, having a designated project manager or coordinator who oversees the activities of different trades and facilitates communication among them can greatly enhance coordination. Regular site inspections and collaborative problem-solving sessions can also help identify and resolve any potential conflicts or issues that may arise during the construction process.

- Q:What are the common safety features of steel props?

- Steel props, also known as adjustable steel props or acrow props, are commonly used in construction and renovation projects to support temporary structures and provide stability. These props have several safety features to ensure the protection of workers and prevent accidents on the job site. 1. Adjustable Height: Steel props are designed with a telescopic mechanism that allows for easy adjustment of the height. This feature ensures that the props can be set at the appropriate level to provide optimal support and stability. 2. Load Capacity: Steel props are engineered to withstand heavy loads. They are typically manufactured with robust materials and are tested to meet specific load-bearing capacities. This ensures that the props can safely support the weight of temporary structures or heavy construction materials. 3. Locking Pins: To prevent accidental collapse or height adjustment, steel props are equipped with locking pins. These pins securely hold the prop at the desired height and prevent any accidental changes. The locking mechanism provides additional safety by ensuring that the prop remains stable throughout the construction process. 4. Prop Head Plate: Steel props feature a flat prop head plate at the top, which provides a larger surface area for distributing the load. This design helps to prevent damage to the supported structure and reduces the risk of the prop sinking into the ground or causing instability. 5. Non-Slip Base Plate: The bottom of the steel prop is typically equipped with a non-slip base plate. This feature improves stability by preventing the prop from slipping or sliding on smooth or uneven surfaces. The non-slip base plate ensures that the prop remains securely in place, reducing the risk of accidents caused by prop movement. 6. Powder Coating or Galvanization: Many steel props are coated with a layer of powder or are galvanized to protect them from corrosion and rust. This protective coating enhances the durability and longevity of the props, ensuring they remain safe to use for an extended period. In conclusion, common safety features of steel props include adjustable height, a high load capacity, locking pins, a prop head plate, a non-slip base plate, and a protective coating. These features are designed to ensure the stability, reliability, and safety of steel props during construction and renovation projects.

- Q:Can steel props be used for temporary support in bridge expansion joint replacement?

- Indeed, temporary support in bridge expansion joint replacement may be achieved through the utilization of steel props. In construction endeavors, steel props find frequent application for the purpose of furnishing provisional support to structures during maintenance or repair activities. With their adjustable nature, durability, and capacity to withstand substantial loads, steel props prove themselves as an optimal selection for sustaining bridge segments throughout the replacement of expansion joints. The installation and alteration of steel props to the desired elevation is a straightforward task, thereby imparting stability and security to the bridge structure. Furthermore, the sturdy construction of these props guarantees their ability to endure the forces exerted during the replacement process, thereby upholding the bridge's integrity.

- Q:Can steel props be used in supporting temporary playground equipment?

- Certainly! Temporary playground equipment can indeed be supported using steel props. In construction and engineering, steel props are frequently employed to offer temporary support to structures. Due to their strength, durability, and ability to bear heavy loads, they are well-suited for supporting playground equipment. However, it is crucial to guarantee the proper installation and anchoring of the steel props, as well as their compliance with essential safety standards, in order to prevent any accidents or injuries. Additionally, regular inspections and maintenance are necessary to ensure the safety and stability of the playground equipment.

- Q:How do you ensure proper load distribution when using multiple steel props?

- To ensure proper load distribution when utilizing multiple steel props, several steps can be taken: 1. Accurately determine the load requirements: It is crucial to precisely calculate the weight or force that needs to be distributed among the props before employing them. 2. Employ an appropriate number of props: The number of steel props needed depends on the load requirements. It is vital to utilize a sufficient number of props to evenly distribute the load. Insufficient props can lead to an uneven distribution, which may result in stress concentration and potential failure. 3. Position the props correctly: The placement of the steel props greatly impacts load distribution. They should be positioned at regular intervals along the load-bearing structure to ensure even distribution. The distance between the props should be determined based on the load requirements and prop strength. 4. Ensure proper alignment: To avoid eccentric loading, the steel props should be aligned accurately. Eccentric loading occurs when the load is not applied at the prop's center, causing an uneven distribution. Ensuring plumb and vertical alignment prevents tilting or leaning. 5. Ensure adequate prop capacity: Each steel prop should possess a sufficient load-bearing capacity to handle the assigned load. It is essential to verify the load capacity of each prop and ensure it surpasses the calculated load requirement. Insufficient capacity can lead to overloading and potential collapse. 6. Regularly monitor and adjust: After setting up the steel props, it is important to regularly monitor the load distribution and make necessary adjustments if any imbalances or shifts occur. Visual inspections, load testing, or monitoring devices can facilitate this process. Regular monitoring enables prompt detection and resolution of potential issues. By adhering to these steps, one can ensure proper load distribution when employing multiple steel props, thereby reducing the risk of structural failures and ensuring the safety of the supported structure or object.

- Q:How to adjust the ratio of steel support to X stable stress and strength design value

- 1, the replacement of the better properties of the cross-section (not necessarily increase the cross-section, to be specific)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Alu-slab

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords