Tripod & Beam Clamp formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Steel Prop & Tripod & Beam Clamp

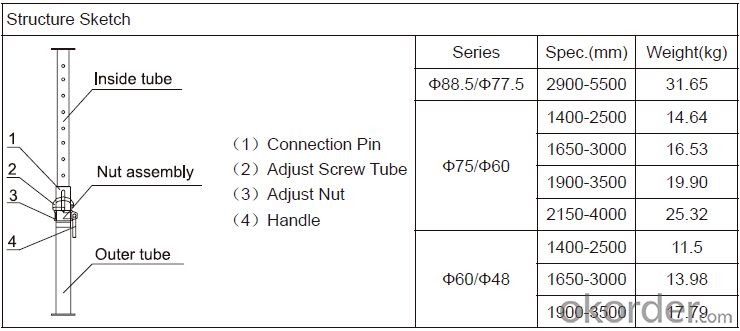

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

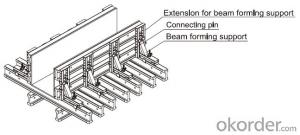

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q:What are the standard safety regulations for using steel props?

- The standard safety regulations for using steel props include ensuring proper installation and alignment, regular inspection for signs of damage or wear, using appropriate load-bearing capacity props for the specific application, and following manufacturer's guidelines for safe usage. Additionally, it is essential to provide adequate bracing and support to prevent accidental collapse, maintain a clear and safe working area, and train personnel on proper handling and dismantling procedures.

- Q:Are steel props suitable for supporting temporary film sets?

- Yes, steel props are suitable for supporting temporary film sets.

- Q:What are the safety training requirements for working with steel props?

- The safety training requirements for working with steel props typically include proper handling techniques, understanding load capacities, and structural stability assessments. It is important to receive training on how to properly assemble, secure, and dismantle steel props to prevent accidents, injuries, or structural failures. Additionally, knowledge of relevant safety regulations, such as wearing appropriate personal protective equipment and implementing fall protection measures, may also be required.

- Q:Can steel props be used in conjunction with other support systems, such as scaffolding?

- Yes, steel props can be used in conjunction with other support systems, such as scaffolding. Steel props, also known as adjustable steel props or adjustable steel shores, are temporary support systems used in construction and renovation projects to support heavy loads or structures. They are typically used to support horizontal beams, slabs, formwork, and other vertical loads. Scaffolding, on the other hand, is a temporary structure used to provide access and support for workers and materials during construction, maintenance, or repair. It consists of platforms, support beams, and other components. In many construction projects, steel props are used in conjunction with scaffolding to provide additional support and stability. For example, if a scaffold is erected to provide access to a higher level, steel props can be used to support the weight of the scaffold and ensure its stability. Similarly, steel props can be used to support scaffold platforms or to reinforce weak areas where additional support is required. The combination of steel props and scaffolding can enhance safety and stability on construction sites, especially when dealing with heavy loads or when working on elevated platforms. However, it is important to ensure that the design and installation of both the steel props and scaffolding are in compliance with relevant safety regulations and guidelines. Proper planning, engineering calculations, and professional supervision are essential to ensure the safe and effective use of steel props in conjunction with other support systems like scaffolding.

- Q:Can steel props be used for temporary support in wastewater treatment plants?

- Yes, steel props can be used for temporary support in wastewater treatment plants. Steel props are commonly used in construction and engineering projects to provide temporary support to structures during construction or maintenance. In wastewater treatment plants, steel props can be used to support various components such as pipes, tanks, and equipment that need to be temporarily lifted or held in place for maintenance, repairs, or modifications. The use of steel props allows for flexibility and stability during these processes, ensuring the safety and efficiency of the wastewater treatment plant operations. It is important to ensure that the steel props used are of appropriate size, strength, and quality to withstand the specific load requirements and environmental conditions of the wastewater treatment plant. Regular inspections and monitoring of the steel props are also crucial to identify any signs of wear, damage, or corrosion, and take necessary actions to maintain their integrity and reliability.

- Q:How do steel props prevent structural collapse during construction?

- Steel props prevent structural collapse during construction by providing temporary support to the structure. These props are adjustable and can be placed strategically to bear the weight of the structure, thus providing stability and preventing any potential collapse.

- Q:Can steel props be used in supporting temporary bridges and walkways?

- Yes, steel props can be used effectively in supporting temporary bridges and walkways. Steel props, also known as adjustable steel props or acrow props, are strong and sturdy support systems that can withstand heavy loads. They are commonly used in construction and temporary structures to provide reliable support and stability. As temporary bridges and walkways require stable and secure footing, steel props are an ideal choice for ensuring the safety and integrity of these structures.

- Q:Are steel props suitable for supporting concrete slabs or beams?

- Yes, steel props are suitable for supporting concrete slabs or beams. Steel props provide adjustable and reliable support, allowing for the proper distribution of weight and load-bearing capacity. They are commonly used in construction projects to provide temporary support during the pouring and curing process of concrete slabs or beams. Steel props offer stability, strength, and flexibility, making them an ideal choice for supporting such structures.

- Q:How do steel props compare to wooden props in terms of strength?

- Steel props are generally much stronger than wooden props in terms of strength. Steel is a highly durable and robust material, capable of bearing heavy loads and providing excellent structural support. It has a high tensile strength, which means it can resist bending or breaking under pressure. On the other hand, wooden props, while still capable of supporting certain loads, are more prone to warping, splitting, or deteriorating over time. They are not as resistant to weight and external forces as steel props. Therefore, in terms of strength and durability, steel props are a more reliable choice for construction or structural support applications.

- Q:Can steel props be used for supporting elevated platforms?

- Support for elevated platforms can be provided by using steel props. These props, also referred to as adjustable steel props or telescopic props, are utilized in construction to offer temporary support to structures like walls, beams, and slabs. They are frequently employed in formwork systems to support elevated platforms during construction. The design of steel props allows for adjustment in height, enabling them to be set at the desired level and provide stable and secure support for elevated platforms. They are typically constructed from high-quality steel, which grants them the necessary strength and durability to withstand heavy loads. Steel props can be easily adjusted and locked into place using a screw mechanism, making them versatile and suitable for various applications. To ensure the proper support of elevated platforms when using steel props, it is crucial to install and position them correctly to evenly distribute the load. The props should be securely placed on a stable and level surface, and their height should be adjusted according to the platform's requirements. Regular inspections and maintenance should also be carried out to ensure the props remain in good condition and can provide reliable support. In summary, steel props are a dependable and widely employed solution for supporting elevated platforms in construction. Their adjustable height, strength, and durability make them suitable for offering temporary support during the construction process.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tripod & Beam Clamp formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products