Steel Prop & Tripod for build formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Steel Prop & Tripod & Beam Clamp

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

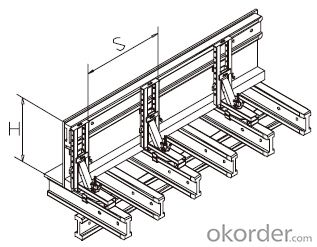

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q:Are steel props resistant to ultraviolet (UV) radiation?

- No, steel props are not resistant to ultraviolet (UV) radiation.

- Q:Full fastener type steel pipe scaffold with all the fastener type steel pipe support frame what is the difference? How to distinguish? Is there a relationship?

- . The construction load of the frame body top layer transfer through the horizontal bar to the top of the pole, the vertical rod is eccentric compression; 2, full frame support is defined in the longitudinal and transverse direction, by not less than three rows of pole and the horizontal bar

- Q:What are the different types of steel props?

- Steel props are adjustable and temporary support structures used in construction to provide support to ceilings, walls, beams, and other structural elements during construction or renovation. There are several types of steel props available in the market, each designed for specific purposes and load-bearing capacities. 1. Adjustable Steel Props: These are the most commonly used type of steel props. They consist of two main parts - an inner tube and an outer tube. The inner tube can be adjusted to the desired height by using a threaded mechanism, allowing for easy installation and adjustment. 2. Push-Pull Props: Also known as shore props, push-pull props are designed to provide support in both compression and tension. They consist of two steel tubes connected by a threaded rod. These props are often used in applications where temporary bracing is required. 3. Light Duty Props: These props are designed for lighter loads and are usually used in residential construction or smaller projects. They are lighter and easier to handle compared to heavy-duty props, making them suitable for less demanding applications. 4. Heavy Duty Props: As the name suggests, heavy-duty props are designed to support heavier loads. They are often used in commercial or industrial construction projects where higher load-bearing capacities are required. These props are usually made from thicker steel tubes and have a larger diameter to provide increased strength and stability. 5. Acrow Props: Acrow props are a specific type of adjustable steel props that have a unique design. They consist of an outer tube, an inner tube, and a pin system that allows for quick and easy adjustment. Acrow props are commonly used in formwork and falsework applications. 6. Trench Props: Trench props, also known as struts, are specifically designed for supporting trench walls during excavation or trenching work. They are adjustable in height and can be easily installed and removed as needed. 7. Formwork Props: Formwork props are used to support formwork systems during concrete pouring. They are designed to withstand high vertical loads and provide stability to the formwork structure. In conclusion, the different types of steel props include adjustable steel props, push-pull props, light duty props, heavy duty props, acrow props, trench props, and formwork props. Each type serves a specific purpose and has varying load-bearing capacities, allowing for efficient and safe temporary support in construction projects.

- Q:Can steel props be used in supporting temporary stages and platforms?

- Yes, steel props can be used in supporting temporary stages and platforms. Steel props, also known as adjustable steel columns or acrow props, are versatile and robust support systems commonly used in construction and temporary structures. They are designed to provide temporary support to horizontal and vertical loads. Steel props are adjustable in height, allowing them to be easily customized to the required height for supporting stages and platforms. Additionally, their strong steel construction ensures stability and safety, making them suitable for supporting heavy loads and providing a secure foundation for temporary structures.

- Q:Can steel props be used in temporary support of heavy machinery?

- Yes, steel props can be used in temporary support of heavy machinery. Steel props are designed to provide strong and stable support for various applications, including the temporary support of heavy machinery. They are known for their durability, load-bearing capacity, and adjustable height features, making them suitable for safely supporting heavy loads during construction, maintenance, or relocation of machinery.

- Q:What are the different types of steel prop connectors available?

- There are several types of steel prop connectors available, including adjustable prop connectors, swivel prop connectors, fixed prop connectors, and snap-on prop connectors. These connectors are used to securely connect steel props or scaffolding systems, providing stability and support during construction or renovation projects.

- Q:Steel support can stay in the wall joint position, if not, then why?

- Note: the I-beam is and even steel cage wall welded together, lifting and reinforcement cage is synchronous lifting installation, when pouring concrete, concrete and steel reinforcement cage are I-beam wrapped inside, while under load

- Q:Do steel props require any special storage or handling procedures?

- Special storage and handling procedures are necessary for steel props. In construction projects, steel props are commonly utilized to temporarily support structures during construction or renovations. To ensure their durability and safety, it is crucial to adhere to specific procedures when it comes to storing and handling steel props. First and foremost, proper storage is vital in order to shield steel props from environmental factors that may cause corrosion or damage. It is recommended that steel props be stored in a dry and well-ventilated area, away from moisture or direct sunlight. If not in use, they should be kept indoors or covered with a waterproof material. Furthermore, careful handling of steel props is of utmost importance to prevent accidents or injuries. Instead of manually lifting them, it is advisable to use appropriate lifting equipment such as cranes or forklifts when lifting or moving steel props. This ensures that the props are not dropped, which could result in potential damage or injuries. Moreover, it is essential to conduct inspections of steel props both before and after each use. Any indications of damage, such as deformations, cracks, or excessive wear, should be promptly addressed. Damaged steel props should not be used and should be either replaced or repaired to uphold the structural integrity and safety of the construction site. In conclusion, special storage and handling procedures are required for steel props to ensure their durability and safety. By adhering to proper storage techniques, employing careful handling practices, and conducting regular inspections, damage can be prevented and the quality of steel props can be maintained, ultimately contributing to a safe and efficient construction process.

- Q:How do you protect steel props from extreme weather conditions?

- To protect steel props from extreme weather conditions, it is essential to apply a protective coating or paint on the surface of the steel. This coating acts as a barrier, preventing direct contact between the steel and the elements. Additionally, regular maintenance and inspections should be conducted to identify any signs of corrosion or damage, allowing for prompt repairs and ensuring the ongoing protection of the steel props.

- Q:Can steel props be used for supporting elevated platforms?

- Yes, steel props can be used for supporting elevated platforms. Steel props are commonly used in construction and scaffolding to provide temporary support for various structures, including elevated platforms. Steel props offer strength, stability, and adjustability, making them suitable for safely supporting elevated platforms during construction or other temporary needs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Prop & Tripod for build formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords