Slab Shuttering Calculation

Slab Shuttering Calculation Related Searches

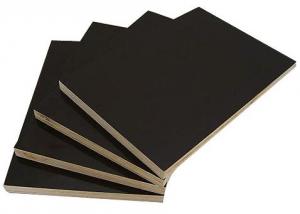

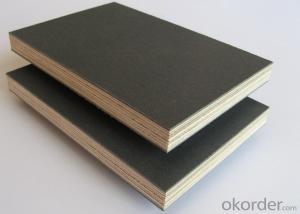

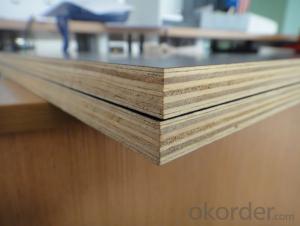

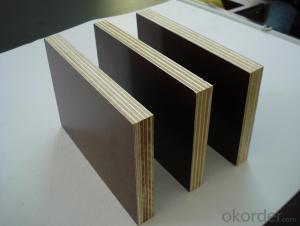

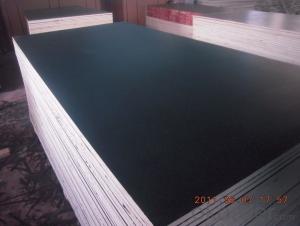

Plywood In Dubai Wacky Board Plywood White Plywood Sheets Metal Laminated Plywood 8 By 4 Plywood Single Ply Plywood 1.5 Inch Plywood Doka Shuttering Material Structural Plywood Sheets 4X10 Plywood SheetsHot Searches

Price Of Century Plywood 19Mm Water Resistant Plywood Price Plywood Prices In Pune 8X4 Plywood Sheets Price 25Mm Birch Plywood Price Century Plywood Price List Gurjan Plywood Price List Kitply Plywood Price List Duro Plywood Price List Trojan Plywood Price List Cost Of Plywood Per Square Metre Greenply 19Mm Plywood Price Gattani Plywood Price Centurion Plywood Price Duro Plywood Price Ikon Plywood Price Ecotec Plywood Price Mwp Plywood Price Cost Of Plywood Waterproof Plywood CostSlab Shuttering Calculation Supplier & Manufacturer from China

Okorder.com is a professional Slab Shuttering Calculation supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Slab Shuttering Calculation firm in China.Hot Products

FAQ

- Shear wall plastic template for the wall height and thick ratio requirements is how much?

- Plastic building template to be extended when the expansion joints: As the plastic building template than the steel mold, wood mold thermal expansion coefficient larger, morning and evening laying plastic template must be reserved for about 2 mm expansion joints (according to the size of the day the temperature difference ), No need to reserve the expansion of the slit at noon. The length of the nail is generally 1.5 inches to 2 inches is appropriate, not too long or too short.

- Plastic building template made of what material

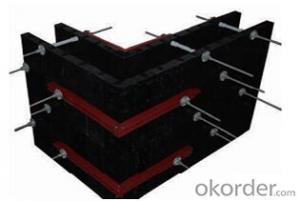

- Template template, as the name implies, is a model (you can think so), and the building template is in the construction of the project, before making the actual product, according to the design pattern, according to the data, such as component dimensions and other related ghosts , To produce a model consistent with the design specifications, and the production of this model is the template material

- What is the economic benefits of building wood formwork compared to plastic molds?

- In summary, what template to use depends on what your structure needs.

- Want to purchase a number of building templates and found a new plastic building template, do not know how the quality?

- Why can not, now the plastic template, called light building materials, China is not yet a few plants can do a good job, after the air-conditioning refrigerator to use this, light and hard, not you like this, you can do with the wall, Now high-end are imported.

- I heard that there are building aluminum template and plastic template it? Which is better?

- Aluminum alloy template is the best architectural template, the advantages of a high number of turnaround, the theory is 300 times, but the actual use of 60 will have a small part of the deformation, a comprehensive calculation of 150 no problem, the second is quick, every worker day Can be assembled 20 square meters or more, three is light weight, manual transmission is very convenient, do not rely on tower crane, four is the quality assurance, the basic can meet the specifications, five is conducive to civilized construction, will not produce garbage and noise, No wood. Disadvantages of a high cost, and second, only in the standard layer to use to play advantage

- Plastic deformation of the template how to solve or why the deformation Thank you I want the reason

- Pvc plate deformation are: physical deformation and chemical deformation.A physical deformation, the cause:???? High temperature lead to deformation, if it is such a deformation, targeted plastic raw materials for high temperature modification, can effectively improve such problems???? Improper textile lead to deformation, such deformation has two reasons, a plate of raw materials can not meet the actual requirements of the product requirements, re-deployment of raw materials formula to meet the actual requirements of the product can be. Second, the processing and storage methods are not correct, leading to deformation, such problems can solve the problem from the rootTwo chemical deformation: mainly the molecular structure of raw materials change.

- The price of raw materials can say better, is the PVC material.

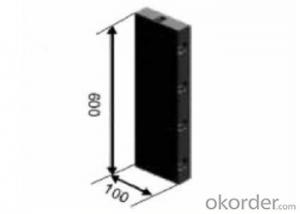

- General templates are fixed specifications, such as 1.22 * 2.44,980 * 2200 so it is generally in accordance with each template to price

- Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- Solid can use foam technology to save costs, there is a hollow drawback in the use of the process, in the corner when the nail easily broken.