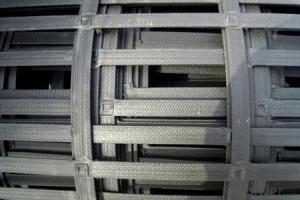

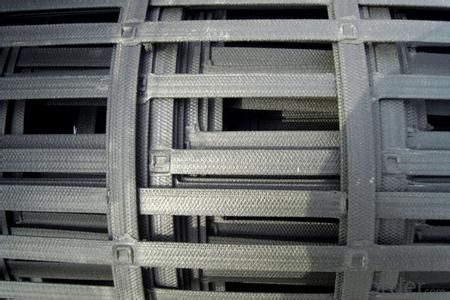

Age Resistance Steel Plastic Geogrid for Civil Engineering

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Black 100% new raw material steel plastic geogrid

suppliers from china

Description

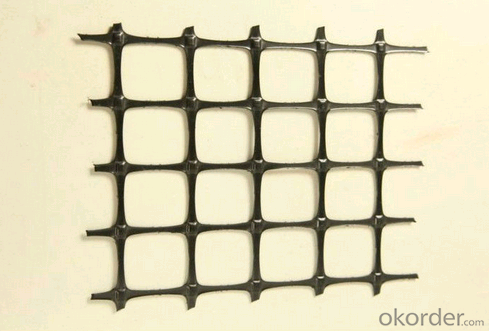

Plastic biaxial geogrid with high strength steel wire (or other fiber), through special processing, and polyethylene (PE) or polypropylene (PP), and adding other assistants, by extrusion into composite type high tensile belt, and the surface is rough textured, for high strength reinforced geotextile strips. The single band, the longitudinal, transverse certain space preparation or clamping arrangement, with special reinforcement welding technology welding the connection point bonding and molding, is reinforced with Geogrid.

Properties

High stength,small deformation, homogenous stucture, easy for constrution etc.

Application

Make reinforcement treatment for varions kinds of sot soil foundation and strengthen shearing resistance of the soil body,used in reinforcement of retaining wall and widening of old road.

It is also used as protect-support net in the coal mine when layer mining of thick (coal) seam, and support of road way in the coal mine.

Specification

| Specifications | GSZ30- 30 | GSZ40-40 | GSZ50-50 | GSZ60-60 | GSZ80-80 | GSZ100- 100 | GSZ150-150 |

| Tensile Strength KN/m(LD) | ≥30 | ≥40 | ≥50 | ≥60 | ≥80 | ≥100 | ≥150 |

| Tensile Strength KN/m(TD) | ≥30 | ≥40 | ≥50 | ≥60 | ≥80 | ≥100 | ≥150 |

| Elongation Rate(LD TD) | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 |

| Tensile Strength at 1% Elongation Rate(LD) | ≥20 | ≥32 | ≥40 | ≥48 | ≥63 | ≥81 | ≥125 |

| Tensile Strength at 1% Elongation Rate(TD) | ≥20 | ≥32 | ≥40 | ≥48 | ≥63 | ≥81 | ≥125 |

| Limit PeelForce at Welded Bonded Point N | ≥100 | ≥100 | ≥100 | ≥100 | ≥100 | ≥100 | ≥100 |

| Products in the range of coal mine | Fire out time from outer flam | ≤3 | |||||

| Surface resistivity | <1×109< span=""> | ||||||

| Packaging Details: | according to your need |

| Delivery Detail: | 7days |

FAQ

1. How about the delivery time?

Lead time since receipt of 30% T/T deposit payment: 3 weeks.

2. What kind of payments does jenor support?

T/T, L/C, Cash are accepted.

3. What's are the MOQ?

We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee If you set the order .

5. Can you produce the product according to customers' requirements ?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

6. Can you tell me your main customers?

That's our customers' privacy, we should protect their information. At the same time, please rest assured that your information is also safe here.

- Q:How do geogrids withstand environmental factors such as UV radiation?

- Geogrids are designed to withstand environmental factors such as UV radiation through the incorporation of UV stabilizers in their manufacturing process. These stabilizers prevent or delay the degradation of the geogrids by UV radiation, enabling them to maintain their strength and durability over an extended period of time.

- Q:Are geogrids suitable for reinforcement of mechanically stabilized earth slopes?

- Yes, geogrids are suitable for reinforcement of mechanically stabilized earth slopes. Geogrids are synthetic materials that can enhance the stability and strength of soil structures by distributing loads and reducing soil movement. They are commonly used in mechanically stabilized earth slopes to improve their stability, prevent erosion, and increase the overall durability of the slopes. Geogrids provide efficient reinforcement and are cost-effective solutions for stabilizing slopes in various engineering and construction projects.

- Q:Are geogrids resistant to corrosion?

- Yes, geogrids are generally resistant to corrosion. They are commonly made from materials such as high-density polyethylene (HDPE) or polyester, which are not prone to corrosion. This makes geogrids suitable for various applications in civil engineering and construction, where they may be exposed to moisture, chemicals, or other corrosive elements.

- Q:Can geogrids be used in geothermal energy systems?

- Yes, geogrids can be used in geothermal energy systems. Geogrids are commonly used in geothermal applications to reinforce the ground and provide stability to the surrounding soil or rock mass. They can help prevent soil erosion, improve load-bearing capacity, and enhance the overall performance and efficiency of geothermal energy systems.

- Q:Can geogrids be used for slope stabilization?

- Yes, geogrids can be used for slope stabilization. Geogrids are engineered materials made from polymers that are used to reinforce and stabilize slopes. They are typically installed in a grid-like pattern and provide strength and stability to the soil, preventing erosion and reducing the risk of slope failure.

- Q:Classification and application of polyethylene geogrid?

- The utility model is suitable for the construction of roads, railways, rivers, lakes, and coastal areas, such as reinforced retaining walls, dams, bridge decks, steep slopes and geocell. Its function is to improve the bearing capacity of the retaining wall or embankment, prolong the service life, reduce the occupation area, shorten the construction period, reduce the cost and reduce the maintenance cost.

- Q:Peel force mainly in the size of raw materials

- The size of the weld area directly affects the size of the peeling force

- Q:What are the application of Geogrid in the construction of cement concrete pavement

- Moreover, as the reinforcement material, can make the road slightly increased the tensile strength, can extend the service life of the road, shorten the construction period

- Q:Are geogrids effective in stabilizing coastal dunes?

- Yes, geogrids are effective in stabilizing coastal dunes. Geogrids provide structural support and reinforcement to the dune system, preventing erosion and enhancing stability. They help to retain sand and prevent its displacement due to wind and water forces, thus preserving the integrity of coastal dunes.

- Q:How do geogrids help in reducing the use of natural resources?

- Geogrids help in reducing the use of natural resources by enhancing the stability and strength of soil, thus reducing the need for excessive excavation and the use of traditional construction materials like stone or concrete. This results in less dependence on natural resources and promotes sustainability in construction projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Age Resistance Steel Plastic Geogrid for Civil Engineering

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords