AA1100 Prepainted Aluminium Coils Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of AA1100 Prepainted Aluminium Coils Used for Construction Description

AA1100 Prepainted Aluminium Coils Used for Construction are of a wide range of colors, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

AA1100 Prepainted Aluminium Coils Used for Construction have been widely used in the fields of construction and decoration, electronic applications, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

2.Main Features of AA1100 Prepainted Aluminium Coils Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

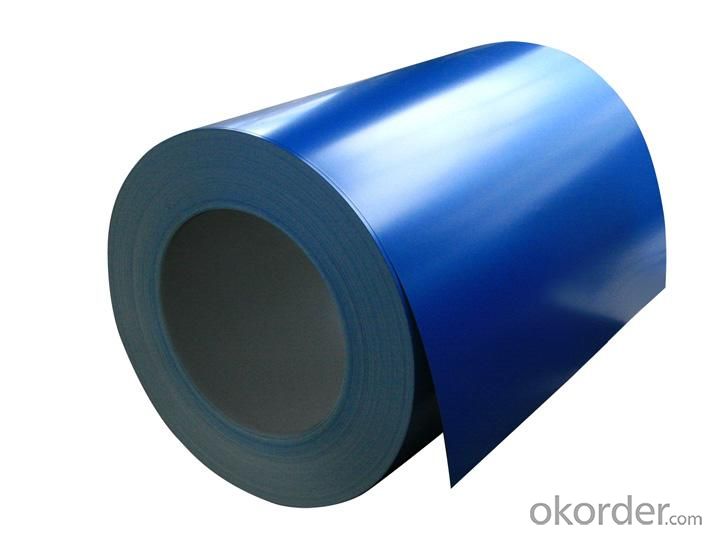

3.AA1100 Prepainted Aluminium Coils Used for Construction Images

4.AA1100 Prepainted Aluminium Coils Used for Construction Specification

Alloy | AA1100 |

Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

Thickness | 0.03mm-3.0mm |

Width | 30mm-1700mm |

Coating | PE,PVDF,Epoxy |

Painting Thickness | Standard 16-25 Mic, max 40 Mic |

Color | According to RAL colors or customers' samples |

Standard | GB/T 17748-1999 |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2000mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q:Can aluminum coils be used for heat dissipation purposes?

- Aluminum coils prove to be highly effective in the dissipation of heat. Due to its exceptional heat conductivity and minimal thermal resistance, aluminum serves as an excellent medium for transferring heat from a source and releasing it into the surrounding environment. Various applications, including refrigeration, air conditioning, radiator systems, and heat exchangers, commonly employ aluminum coils. These coils are designed to optimize the available surface area for heat transfer, thereby ensuring efficient cooling and dissipation. Moreover, aluminum possesses the advantages of being lightweight and resistant to corrosion, making it a practical choice for heat dissipation across diverse industries. Overall, aluminum coils emerge as a dependable and efficient solution for heat dissipation purposes.

- Q:How long do aluminum coils last?

- The lifespan of aluminum coils can vary depending on various factors such as maintenance, usage, and environmental conditions. On average, well-maintained aluminum coils can last between 15 to 20 years. However, with proper care and regular cleaning, some aluminum coils have been known to last even longer, up to 30 years or more. It is important to note that regular maintenance, such as cleaning the coils, checking for any damage or corrosion, and ensuring proper airflow, can significantly extend the lifespan of aluminum coils. Additionally, factors like exposure to harsh weather conditions, humidity levels, and the quality of installation can also impact the longevity of aluminum coils.

- Q:I wrap everything with aluminum foil and bake it in the oven -- fish, meat, vegetables. Is this really safe? Or safe when done occasionally? Or should I find a new way?

- I use aluminium foil often for baking however I use baking paper between the food and the foil. I am sure it is safe to use foil, however I find that on occasions the foil sticks to the food, so I use the non stick paper between. I hope this helps.

- Q:Are aluminum coils compatible with other materials?

- Yes, aluminum coils are compatible with other materials. Aluminum is a versatile and widely used material that can be easily integrated with various other materials in different applications. For example, aluminum coils can be used in conjunction with copper tubing in air conditioning and refrigeration systems to enhance heat transfer efficiency. Additionally, aluminum coils can be coated or laminated with other materials such as polymers or paints to provide additional protection against corrosion, improve aesthetics, or enhance specific performance characteristics. Therefore, aluminum coils offer compatibility with a range of materials, making them suitable for diverse applications in industries such as construction, automotive, aerospace, and more.

- Q:Can aluminum coils be used in the manufacturing of cans?

- Yes, aluminum coils can be used in the manufacturing of cans. Aluminum coils are often used to produce the thin sheets of aluminum that are then formed into cans. The coils are typically processed through a series of steps, including rolling, annealing, and slitting, to create the desired thickness and width for can production. The aluminum sheets are then cut into appropriate sizes and shaped into the familiar cylindrical can shape. Aluminum is a popular choice for can manufacturing due to its lightweight, durable, and corrosion-resistant properties. It also provides a barrier to light, oxygen, and moisture, helping to preserve the quality and shelf life of the contents inside the cans. Overall, aluminum coils are an essential component in the manufacturing process of cans and play a significant role in the packaging industry.

- Q:What is the maximum width-to-thickness ratio for aluminum coils?

- The maximum width-to-thickness ratio for aluminum coils depends on various factors, including the specific alloy, temper, and intended application. Aluminum coils are commonly used in industries such as construction, automotive, and packaging, where different width-to-thickness ratios may be required. In general, the width-to-thickness ratio for aluminum coils typically ranges between 100:1 to 200:1. However, it is important to note that this range can vary based on the specific alloy and temper. Thicker coils may have a lower width-to-thickness ratio, while thinner coils can have a higher ratio. High-strength alloys, such as those used in aerospace applications, may have lower width-to-thickness ratios due to their increased strength requirements. Conversely, coils used in less demanding applications may have higher width-to-thickness ratios. It is crucial to consult the relevant industry standards, specifications, or manufacturer guidelines to determine the appropriate width-to-thickness ratio for a specific aluminum coil. These guidelines consider the intended use, mechanical properties, and performance requirements, ensuring that the coil is suitable for its intended application while maintaining structural integrity and functionality.

- Q:The temperature of the water drops from 93.0°C to 78.0°C. What quantity of heat energy did the piece of aluminum absorb?

- The specific heat of Aluminum is 0.215 cal/g-°C. The calories absorbed (q) would be q = m * c * (T2 -T1) = 22.0 g * 0.215 cal/g-°C * (78.0 °C - 0.3 °C) If you have a different value for the Specific heat of Aluminum, use it in the formula for your calculations. If you knew the mass of the water, you could check your calculations because the heat gained by the Al would be equal to the heat lost by the water, using q = m * c * (T2 -T1), where m is the mass of the water, c = 1.00 calorie/gram °C, T2 = 78.0 °C and T1 = 93.0 °C. The sign of q will be negative.

- Q:Can aluminum coils be used for heat exchangers?

- Yes, aluminum coils can be used for heat exchangers. Aluminum is a popular choice for heat exchangers due to its excellent thermal conductivity, lightweight nature, and corrosion resistance. These coils are typically used in applications where heat transfer is required, such as in HVAC systems, refrigeration units, and automotive radiators. The high thermal conductivity of aluminum allows for efficient heat transfer, while its corrosion resistance ensures durability and a longer lifespan for the heat exchanger. Additionally, aluminum coils can be easily formed into various shapes and sizes, making them versatile for different heat exchanger designs.

- Q:Are aluminum coils resistant to mold and mildew?

- Yes, aluminum coils are highly resistant to mold and mildew. Aluminum does not provide a favorable environment for mold or mildew growth, making it an excellent choice for applications where moisture and humidity are concerns.

- Q:I am shopping for new Rollerblades and see their newer skates have Aluminum framesand not the composite which I feel is more sturdier. What do you think of the aluminumframes? I was not impressed.

- Technically okorder /... that were extremely good but the deal probably fell apart when the original Mogema was dissolved.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AA1100 Prepainted Aluminium Coils Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords