33116 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specificatioin of Taperder Roller Bearings:

The tapered roller bearing is to bear the combination of radial and axial load but mainly afford radial load. The loading capibility is determined by the raceway angle of outer ring, the larger angle afford larger load. This kind of bearings can be seperated and it can be divided into single-row and double-row tapered roller bearings by the number of columns. The clearance for single-row tapered roller bearing should be adjusted by the customers when installation. For the double-row tapered roller bearings,the clearance has already set by the manufacture before ex-factory. Tapered roller bearing has taper shaped inner ring and outer ring raceway,and the roller elements arrange between them. All projection lines from the surface of rollers meet at the same point on bearing axis. This design makes tapered roller bearings particular suitable for combined (axial and radial) loads.The axial loading capacity is determined by the contacting angle α, the bigger angle for α, the larger axial loading capacity is. Tapered roller bearing is usually a seperated bearing, that is,the inner ring assembly including roller and cages, is seperated installed with the cup.

Taper roller bearings are mainly used for radial and axial joint load with radial load as main subject. Axial load capacity relies on raceway angle of outer ring: the bigger the angle is, the bigger the bearing capacity is. Outer ring can be separated and can be easily assembled. During installing and using process, axial clearance and radial clearance and radial clearance can be adjusted and pre-interference installation can be allowed.

Product application:

In many applications tapered roller bearings are used in back-to-back pairs so that axial forces can be supported equally in either direction.

- car and vehicle wheel

- mining equipment

- moderate speed

- engine motors

- axle systems

- construction

- agriculture

- reducers

- gear box

- Q:Can tapered roller bearings be installed in a vertical direction? In a vertical direction rather than in a horizontal direction..

- Whether horizontal mounting or vertical installation, the axial direction is axial and radial is radial

- Q:that is to say, the taper head is the face and the back is the back

- The installation of tapered roller bearings is not only to pay attention to the direction of installation, there are many other places to pay attention to, is a very professional technical activities

- Q:What are the general uses of tapered roller bearings?

- At the time of greater radial load and axial load

- Q:What items should be inspected for tapered bearings?

- 4, tapered roller bearing ring after the whole machine after pickling, there should be no scald, the name of cooperation should not be a pickling visible traces of burns, and no response angle detection.Tapered roller bearing appearance should be smooth, lubrication, no plants, no scratches, no rust and no obviously difference, promised to pressure injury, damage, deformation and defects such as trachoma vipassana.

- Q:There are many kinds of tapered roller bearings, because of work requirements, test the external size is qualified, I want to make a test, to test the bearing is qualified, mainly inside and outside diameter and inside and outside the ring height tolerances, diameter ranging from 50mm--80mm, score less, look forward to your help, I thank you there are 322163311532215 main bearings, 313113002

- Less points, huh, huh?Bearings are tested with a dedicated bearing inspection instrumentTable seat:Outside diameter D913Internal diameter D923Height G904With standard and special micrometer (usually microkators and leverage comparator)Each inspection procedure has the corresponding inspection instructionYou can provide the job instructions free of charge to your bearings suppliers as a project to review their process controlAs for the instrument, you should pay for it even if your supplier offers itIf you buy the bearings in the retailers, then you have to pay for them yourselfThe work instructions may also have to be replaced by money

- Q:Tapered roller bearings, 70 in diameter, please tell me the model number

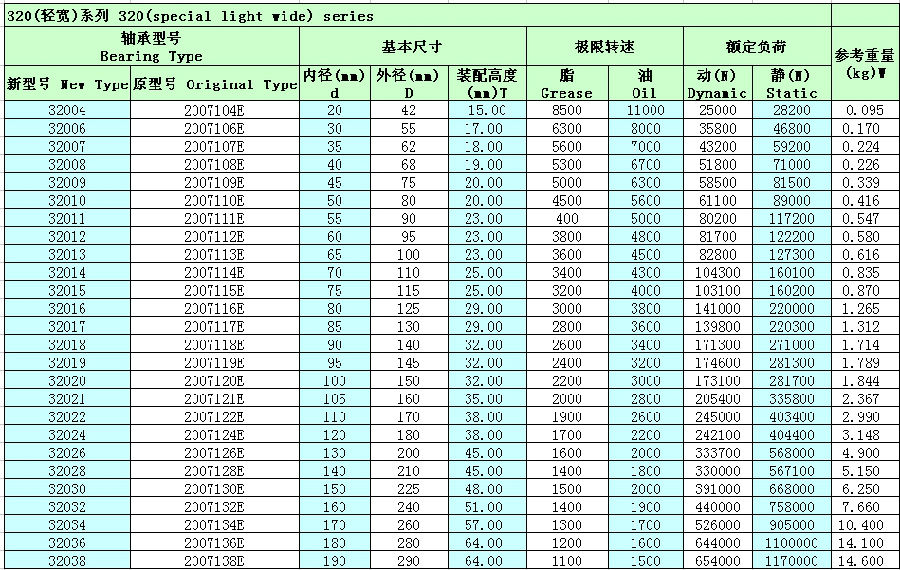

- What about outside diameter (D) and width (B)? You didn't say?.Following are all series of codes and sizes for tapered roller bearings (single column and double row). I hope they can help.Single row tapered roller bearings (taken from GB/T 297-1994)Bearing code |30000: 32914 X2Basic size /mm|d: 70Basic dimensions /mm| D: 100Basic size /mm|T: 20Basic size /mm|B: 19Basic size /mm|C: 16Installation size /mm|da (min):-Installation size /mm|db (max):-Installation dimension /mm| Da (min):-Installation size /mm|Da (max):-Installation size /mm|Db (min):-Installation size /mm|a1 (min): 4Installation size /mm|a2 (min): 6Installation size /mm|ra (max): 1Installation size /mm|rb (max): 1The other is /mm|a size: 19Other sizes /mm|r (min): 1Other sizes /mm|r1 (min): 1The calculated coefficient is |e: 0.33The calculated coefficient is |Y: 1.8The calculated coefficient is |Y0: 1Basic rated load /kN|Cr: 53.2Basic rated load /kN|C0r: 85.5The speed limit / (r/min) | fat: 3600The speed limit / (r/min) | oil: 4500The weight is /kg|W:-

- Q:Taper roller bearings limit speed, according to what to calculate, there is no formula for what?

- First of all, different types of tapered roller bearings, the limit speed is different. Bearing on catalog.Second, the calculation of bearing limit speed is calculated by computer simulation of bearing manufacturer. It is very complicated. Mainly based on frictional heat generation and cage strength limit.So, we use bearing technology or design personnel, only need to control your speed in the following catalog bearing manufacturers can.In addition, oil lubrication is better than grease lubrication at the same speed.

- Q:The installation of tapered roller bearings

- 2, when installed, the direction of the roller tilt there is a regulation? Must be the same as the following picture?:You say that the direction of the tilt is actually the same direction of the bearings, the installation of the problem to different ah!

- Q:What is the 30207 judgment coefficient e of tapered roller bearings?

- Your adoption is the driving force of my progress~~O (a O, a _) remember praise and adoption, help each other.

- Q:What is the size of tapered roller bearings 352214?

- Bearing type: tapered roller bearingNew model: 352214Old model: 97514EInternal diameter (mm):70Outside diameter (mm):125Width (mm):75

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

33116 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords