32020 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

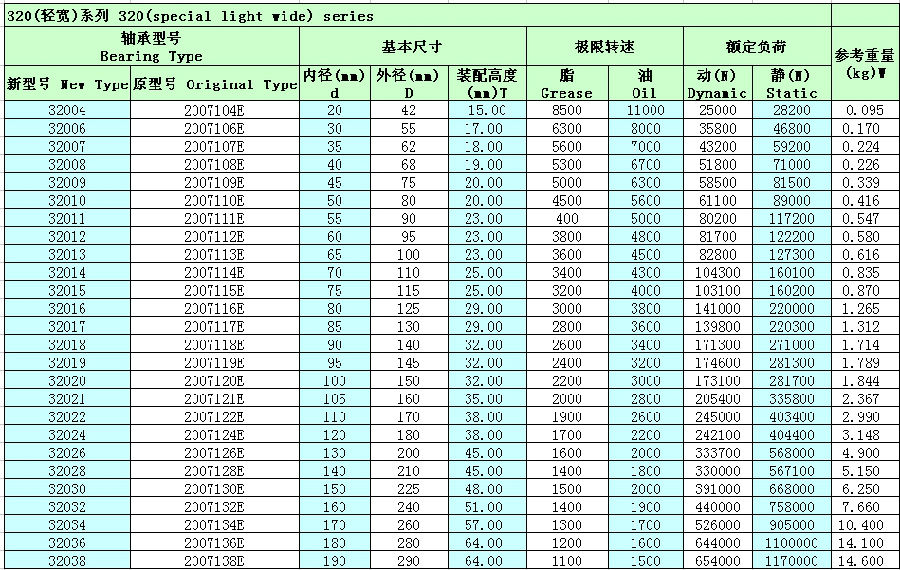

Specificatioin of Taperder Roller Bearings:

The tapered roller bearing is to bear the combination of radial and axial load but mainly afford radial load. The loading capibility is determined by the raceway angle of outer ring, the larger angle afford larger load. This kind of bearings can be seperated and it can be divided into single-row and double-row tapered roller bearings by the number of columns. The clearance for single-row tapered roller bearing should be adjusted by the customers when installation. For the double-row tapered roller bearings,the clearance has already set by the manufacture before ex-factory. Tapered roller bearing has taper shaped inner ring and outer ring raceway,and the roller elements arrange between them. All projection lines from the surface of rollers meet at the same point on bearing axis. This design makes tapered roller bearings particular suitable for combined (axial and radial) loads.The axial loading capacity is determined by the contacting angle α, the bigger angle for α, the larger axial loading capacity is. Tapered roller bearing is usually a seperated bearing, that is,the inner ring assembly including roller and cages, is seperated installed with the cup.

Taper roller bearings are mainly used for radial and axial joint load with radial load as main subject. Axial load capacity relies on raceway angle of outer ring: the bigger the angle is, the bigger the bearing capacity is. Outer ring can be separated and can be easily assembled. During installing and using process, axial clearance and radial clearance and radial clearance can be adjusted and pre-interference installation can be allowed.

Product application:

In many applications tapered roller bearings are used in back-to-back pairs so that axial forces can be supported equally in either direction.

- car and vehicle wheel

- mining equipment

- moderate speed

- engine motors

- axle systems

- construction

- agriculture

- reducers

- gear box

- Q:Online cylinder cones are GB/T4663, what do you mean?

- National standard GB 4663-1984, roller bearings, thrust cylindrical roller bearings, size, please check the mechanical design manual (Fifth Edition), second volumes --- commonly used rolling bearings, dimensions and performance parameters / thrust roller bearings.

- Q:What are the E and Y values of the 30209 bearings of tapered roller bearings?

- The shoulder of the positioning shaft is positioned; the transition shaft shoulder is provided for the disassembly of the parts on the shaft or the prevention of the stress concentration. But the axial shoulder will inevitably increase the diameter of the shaft, and the shoulder of the axle will change due to the stress concentration.

- Q:Tapered roller bearings. Are the rollers tapered?

- The frustum of the cone can be seen as a right angled trapezoid revolving around the right angle, and the top is a circle. Can also be seen on top of the tip is tapered off, the tapered roller head is not a round face

- Q:Can tapered roller bearings be installed in a vertical direction? In a vertical direction rather than in a horizontal direction..

- Absolutely. The bearing below the figure is the tapered roller bearing placed vertically.

- Q:that is to say, the taper head is the face and the back is the back

- The bearings do not have to distinguish between the front and back, and there is no positive and negative said, only in accordance with your actual use to identify the installation direction.

- Q:What items should be inspected for tapered bearings?

- 2, tapered roller bearings are not allowed to have an electric drill pattern, vibration patterns, yin and Yang face and polished traces, did not promise to emerge supporting construction and obvious measurement traces, did not agree to knock bumps and obvious color difference.3, the name of the whole machine did not promise to have oxide skin.

- Q:Tapered roller bearings 32010x, two matching, how to install?

- Bearing type: tapered roller bearingNew model: 32010XOld model: 2007110EInternal diameter (mm):50Outside diameter (mm):80Width (mm):19Tapered roller bearings are mainly used to support radial load and axial load, which should not be subjected to axial load alone.

- Q:Why is the cage of tapered roller bearings loose?

- It is loose, the outer frame of the bearing cone is removable, as long as it is easy to install and add lubricant. You can come up with the relevant standards, must belong to the bearing standard parts, as long as you meet the standard requirements of the bearing can be spread!

- Q:How does the roller of tapered roller bearings fit in?

- Tapered roller bearings itself can be broken down, and new (or old) bearings are cleaned and decomposed. So do not worry, carefully installed in accordance with the original installation order on the line, and if it does not meet the installation order, the installation of this bearing is not go on.

- Q:Tapered roller bearing: Bearing expert why burned or locked

- Shaft tolerance is relatively small and fine head, the inner shell inside and nose has obvious signs of friction. If there are traces of friction on one side or on both sides of the inner shell, there is an abnormal contact with the inner shell of the bearing and the friction of the inner shell of the bearing.2, the inner shell shell burning marks are not serious, roller black even deformation, generally is the inner shell or casing tolerance, Ambassador bearing gap smaller, and even negative tolerance caused by burning. Or in the maintenance of the bearing selection is not correct, you can use large clearance bearings.3, the shell burned seriously, the inner shell, roller are no obvious changes, you can observe whether the shell has traces of friction. There are traces of friction on the outside, and it can be considered that the tolerance between the bearing shell and the shaft is insufficient, which results in abnormal friction caused by the slipping of the housing. If there are traces of friction on one side or on both sides of the shell, there is an abnormal contact between the component relative to the bearing housing and the bearing housing, and the heat generated by friction will be burned out.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

32020 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords