33117 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

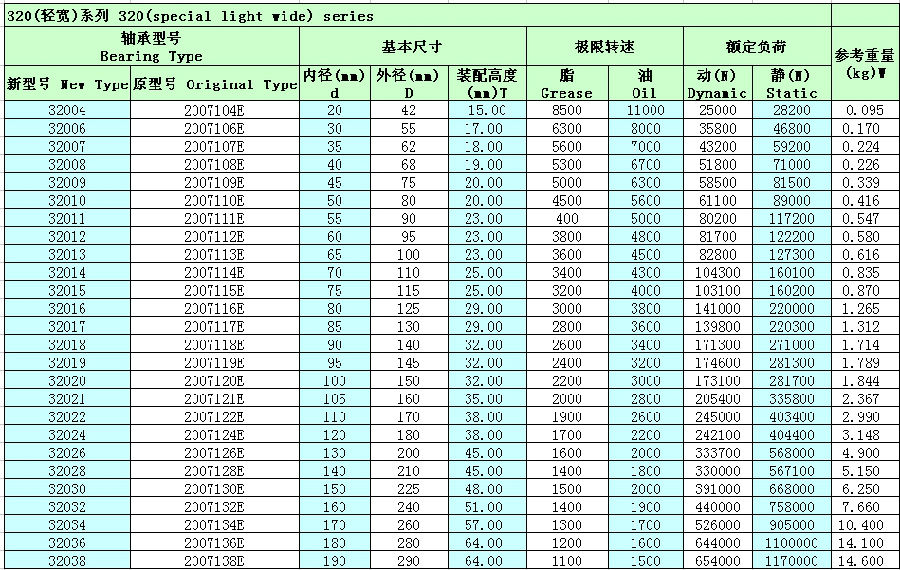

Specificatioin of Taperder Roller Bearings:

The tapered roller bearing is to bear the combination of radial and axial load but mainly afford radial load. The loading capibility is determined by the raceway angle of outer ring, the larger angle afford larger load. This kind of bearings can be seperated and it can be divided into single-row and double-row tapered roller bearings by the number of columns. The clearance for single-row tapered roller bearing should be adjusted by the customers when installation. For the double-row tapered roller bearings,the clearance has already set by the manufacture before ex-factory. Tapered roller bearing has taper shaped inner ring and outer ring raceway,and the roller elements arrange between them. All projection lines from the surface of rollers meet at the same point on bearing axis. This design makes tapered roller bearings particular suitable for combined (axial and radial) loads.The axial loading capacity is determined by the contacting angle α, the bigger angle for α, the larger axial loading capacity is. Tapered roller bearing is usually a seperated bearing, that is,the inner ring assembly including roller and cages, is seperated installed with the cup.

Taper roller bearings are mainly used for radial and axial joint load with radial load as main subject. Axial load capacity relies on raceway angle of outer ring: the bigger the angle is, the bigger the bearing capacity is. Outer ring can be separated and can be easily assembled. During installing and using process, axial clearance and radial clearance and radial clearance can be adjusted and pre-interference installation can be allowed.

Product application:

In many applications tapered roller bearings are used in back-to-back pairs so that axial forces can be supported equally in either direction.

- car and vehicle wheel

- mining equipment

- moderate speed

- engine motors

- axle systems

- construction

- agriculture

- reducers

- gear box

- Q:Online cylinder cones are GB/T4663, what do you mean?

- National standard GB 4663-1984, roller bearings, thrust cylindrical roller bearings, size, please check the mechanical design manual (Fifth Edition), second volumes --- commonly used rolling bearings, dimensions and performance parameters / thrust roller bearings.

- Q:What are the general uses of tapered roller bearings?

- Widely used in machinery and equipment, water conservancy and Hydropower Engineering, railway, automobile, steel, textile, packaging, medicine, metallurgy, mining, petroleum, electric power, papermaking, computer, motor, sports equipment, office equipment, instrumentation, auto motor, precision instruments and other fields

- Q:Tapered roller bearings 32010x, two matching, how to install?

- Suitable for heavy load and impact load. In addition to single row bearings, tapered roller bearings include double row bearings, pairs of double bearings and four row bearings. The taper roller bearing holder usually adopts a punch holder.

- Q:What are the conditions for the normal and reverse loading of tapered roller bearings?

- When the transmission parts between the two bearings, the formal wear of the pressure center to reduce the distance, and help to improve the rigidity of the shaft, the reverse is the opposite. Therefore, two contact ball bearing or tapered roller bearing suits and reverse installation should be based on the transmission parts (gear, worm) considering the structure and the axis. And choose to use.

- Q:Taper roller bearings are used on my motor. Serious damage occurred during use. Please help me analyze the possible causes of damage! Thank you

- But it is worth noting that you must control your parts tolerances, affect the tolerance of your variables clearance values are 11, 1 respectively -- bearing outer ring end face of large tolerances; 1 large end bearing inner ring outer ring end face 2 large tolerances; tolerances of bearings; 2 large end face of the inner face of tolerance between the two bearings, bearing; the small ring thickness tolerances; spacer ring tolerances; axial length tolerances; and two bearing diameter tolerances, and the corresponding axis tolerances (same axis but not at the same time processing is considered as two independent variables), consider the last four variables is because of you this application should be tightly matched with the inner ring, it will affect the clearance.

- Q:There is a slot in the inner ring of tapered roller bearings, right? Is the roller in the slot?

- Yes.AskIs there a gap between the roller and the slot when the roller is placed in the slot?Chasing the answerNo

- Q:What is the 30207 judgment coefficient e of tapered roller bearings?

- What do you need to see for yourself?:Tapered roller bearings: 30207Internal diameter d:35mmOutside diameter D:72mmInner ring height B:17mmOuter ring height C:15mmTotal height (assembly height) T: 18.25mm

- Q:Tapered roller bearing: Bearing expert why burned or locked

- 1, improper choice of bearing clearance.For example: C3 group should be selected for clearance, and the actual use of ordinary group clearance. Because when the bearings work will continue to accumulate heat, shaft diameter and inner ring and outer ring rolling body will swell, because good radiating condition of expansion is relatively small, the whole bearing clearance becomes small, or even negative clearance larger.At this time, stress increases between the body and the rolling roller pressure, lubrication conditions decreased, there will be the phenomenon of boundary lubrication or even local steel on steel friction, so the temperature continues to rise, the base oil in lubricating grease evaporation, so lead to vicious spiral bearing overheating burned, rolling annealing into blue black color, then bearing the friction increasing roller holder to stop COLLOPSE bearing lock.

- Q:Turbine turbo rod reduction box, tapered roller bearing at both ends of wormGap measuring method, tapered roller bearingsThe gap is +-0.03, so how do I know the gap is in the range?.

- This should be accomplished by tightening the clearance of the gear box end cover.

- Q:What is the size of tapered roller bearings 352214?

- Bearing type: tapered roller bearingNew model: 352214Old model: 97514EInternal diameter (mm):70Outside diameter (mm):125Width (mm):75

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

33117 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords