2.5 Tons Battery Powered Forklift CPD25C

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forklift Description:

Specialty trucks

At the other end of the spectrum from the counterbalanced forklift trucks are more 'high end' specialty trucks:

Articulated Counterbalance Trucks

These are, unlike most lift trucks, front wheel steer, and are a hybrid VNA (Very Narrow Aisle) truck designed to be both able to offload trailers and place the load in narrow aisle racking. Increasingly these trucks are able to compete in terms of pallet storage density, lift heights and pallet throughput with Guided Very Narrow Aisle trucks, while also being capable of loading trucks, which VNA units are incapable of doing.

Guided Very Narrow Aisle Trucks

These are rail or wire guided and available with lift heights up to 40' non-top-tied and 98' top-tied. Two forms are available; 'man-down' and 'man-riser' where the operator elevates with the load for increased visibility or for multilevel 'break bulk' order picking. This type of truck, unlike Articulated Narrow Aisle Trucks, requires a high standard of floor flatness.

Omni-directional Trucks

Omni-directional technology (such as Mecanum wheels) can allow a forklift truck to move forward, diagonally and laterally, or in any direction on a surface. Omni-directional wheel system is able to rotate the truck 360 degrees in its own footprint or strafe sideways without turning the truck cabin. One example is the Airtrax Sidewinder. This forklift truck has also made an appearance in the TV -series called 'Mythbusters'.

Forklift Specification:

Model | CPD25C | |

Load capacity kg | 2500kg | |

Load center mm | 500mm | |

Power type | Battery | |

Max.lifting speeds | 230mm/s | |

(with load)mm/s | ||

Max.Driving speeds | 12/14km/h | |

(with without load)km/h | ||

Max.Towing speeds | 10kN | |

(with load)kN | ||

Gradeability(with load)% | 15% | |

Lifting height mm | 3000mm | |

Free lift mm | 60mm | |

Tilting angles | 6/12(forward-backward) 。 | |

Min. turning radius mm | 2250mm | |

Min. right angle aisle width mm | 2100mm | |

Min. under-clearance mm | 110mm | |

Dimensions | A Overall length (inincluding fork) mm | 3380 |

B Overall width mm | 1160 | |

H Overall height(mast lowered) mm | 2130 | |

H2 Overall height(mast extend) mm | 4040 | |

H3 Overall height to overhead guard mm | 2130mm | |

B3 Fork width mm | 122mm | |

H4 Fork thickness mm | 40mm | |

A3 Fork length mm |

| |

A1 Fork overhang mm | 451mm | |

A2 Wheel base mm | 1550mm | |

Tread | Front tread mm | 970mm |

Rear tread mm | 950mm | |

Tyre | Front tyre | 7.00-12mm |

Rear tyre | 18×7-8mm | |

Total weight kg | 4300 | |

Motor | Traction motor | XQ-8 |

Lifting motor | XQD-10-3S | |

Battery | Battery type | D-700 |

Battery voltage/Capacity V/Ah | 48/700 | |

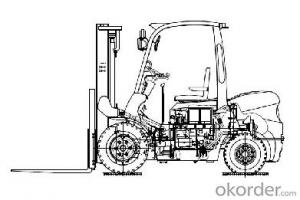

Forklift Images:

FAQ of forklift:

Q: What’s the function of forklift?

A: A forklift truck (also called a lift truck, a fork truck, or a forklift) is a powered industrial truck used to lift and move materials short distances. The forklift was developed in the early 20th century by various companies including the transmission manufacturing company Clark and the hoist company Yale & Towne Manufacturing. Following World War II the use and development of the forklift truck has greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing operations.

Q: What’s the general operations of forklift:

A: Forklift cab with control layout.

Forklifts are rated for loads at a specified maximum weight and a specified forward center of gravity. This information is located on a nameplate provided by the manufacturer, and loads must not exceed these specifications. In many jurisdictions it is illegal to remove or tamper with the nameplate without the permission of the forklift manufacturer.

Q: What are the Forklift safety Standards?

A: 1, Forklift safety is subject to a variety of standards world wide. The most important standard is the ANSI B56—of which stewardship has now been passed from the American National Standards Institute (ANSI) to the Industrial Truck Standards Development Foundation after multi-year negotiations. ITSDF is a non-profit organization whose only purpose is the promulgation and modernization of the B56 standard.

2, Other forklift safety standards have been implemented in the United States by the Occupational Safety and Health Administration (OSHA) and in the United Kingdom by the Health and Safety Executive.

3, Driver safety: In many countries forklift truck operators must be trained and certified to operate forklift trucks. Certification may be required for each individual class of lift that an operator would use.

- Q:How to drive a forklift

- Maintenance of words All you have to check good oil daily These can be the dalai And to a certain range to wash the change of the change of the wash everything OK the dalai

- Q:Skill and use of side forklift?

- The quality of the side forklift truck, the cable rod, the wood grasping wooden machine, for grasping the log, the branch, the wood, etc. Grasp the wood machine and tractor common hydraulic oil cylinder, hydraulic element devices standardization degree is high, easy to use diesel maintenance loader all show high input, high torque, low fuel consumption, power is great. The loader dipper Angle inductance control, can realize any position automatic level. Forklift fork structure is optional: fixed, adjustable. The brake mode of grasping machine can be chosen with inflatable brake, break air brake and oil brake, etc., which can be produced in various kinds. When holding the wooden machine, use the fast handle to roll up the leg. Four-wheel brake with pneumatic top oil pliers. The profile of the side forklift: the frame of the side forklift, the lifting mechanism and the fork in the middle of the forklift truck, can be moved along the lateral track. The fork is on the side of the forklift truck, and there is a cargo platform on the side. When the cargo fork rises to the height of the cargo platform, the door frame is retracted down the rail and down the cargo fork. The cargo is placed on the cargo platform of the forklift truck. Side forklift on the side of the car. The body enters the channel, the fork is facing the shelf or the cargo stacking, the loading and unloading operation does not need to turn before the operation.

- Q:How does flexsim implement a forklift truck to move the product to the shelf

- For example, a forklift truck lifts the cargo from the staging area to the shelf: First, the temporary storage areas, shelves and forklifts are established.

- Q:How long does the electric forklift replace the battery

- It's about two to three days 1.5 meters * 2 = 3 meters, Two tons of electric bottle forklifts are fully available at a height of 1.1 tons For now, domestic batteries need to be replaced with 750 charges. At your current workload, it will take at least four years. Of course also need to see the maintenance condition of the battery, maintain good can be able to use a bit longer. If the operation error is likely to be replaced in two or three years The product is detailed to the website of the company

- Q:Is there a driving permit for the forklift truck?

- You don't have to travel. He's just a machine in the factory, but you have to operate the license. The operation certificate is the above certificate

- Q:I want to learn about the forklift truck. I don't know how well the forklift man works.

- Friend hello, forklift words don't go to school, you can find companies to practice, to find relationship between warehouse and his lane, can learn, then it is ok to go to the school take an examination of a certificate,

- Q:What about the exhaust fumes of the internal combustion fork in the workshop

- A forklift exhaust gas purifier. Shanghai jiekai supplies imported forklift exhaust gas purifiers, which is 90 percent efficient.

- Q:Where are the advantages and disadvantages of a battery lifter and a diesel forklift

- chassis The driving system is a device that ensures the forklift rolls and supports the entire forklift, consisting of a scaffold, a bridge, a wheel, and a suspension device. Forklift drive axle, front axle for this is to increase the load carrying the front axle shaft, in order to improve the driving wheel on the adhesive quality, increase the surface adhesion, to ensure that the driving force of the engine to be able to give full play to. The rear bridge is to the bridge. The steering gear is located in front of the driver, and the lever, such as a gearbar, is placed on the right side of the driver's seat.Steering system is used to make the forklift is decided according to the driver's intention to walk in the direction of the system, forklift steering system according to the energy needed for the steering is different, can be divided into mechanical steering system and power steering system. The former USES the power of the driver to turn to energy, which is made up of the steering gear and steering gear and the steering mechanism. The latter is a combination of driver's physical and engine power steering. In normal circumstances, the forklift turns to the required energy, and only a small portion of it is supplied by the driver, mostly by the engine. The steering mechanism is provided. But in the case of a switch to a power plant, the driver will generally be able to take the steering wheel. In the case of forklift, the steering wheel is used to reduce the driver's load. The usual power steering gear has the integral power steering, the semi-integral power steering and the steering force..

- Q:What is the difference between a forklift and an operation certificate

- The operation certificate also is called the job card is issued by the bureau of quality supervision, belongs to special operation personnel, meaning is to have this card first to be able to work on the job. The classification certificate of the forklift truck is the professional qualification certificate and the human resources social security bureau. Junior intermediate senior technician, etc., mainly to prove the performance level of the holding witness

- Q:The forklift card has been tried for several years

- Forklift driving license (forklift license) is issued by the state production safety supervision and administration of the People's Republic of China special operations card ", forklift only used in the unit within the work place.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

2.5 Tons Battery Powered Forklift CPD25C

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords