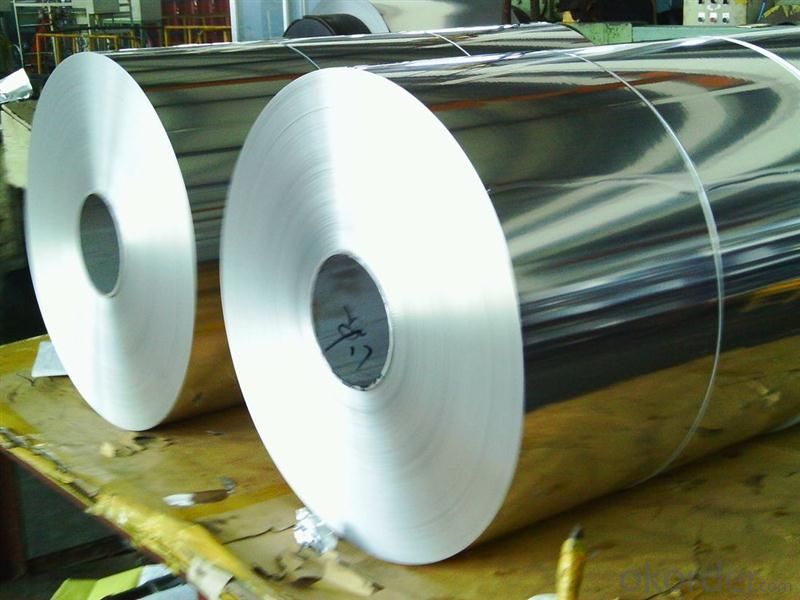

1060 Temper H18 0.5mm 0.6mm 0.7mm Thick Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1060 Temper H18 0.5mm 0.6mm 0.7mm Thick Aluminum Coil

Applications:

Aluminum foil roll is widely used in construction,decoration,hardware,

electric appliances,machinery and other industrial and civil purposes,

such as electronic capacitor,composite cooker,rice cooker,refrigerator,

computer casting,telecommunication,equipment,lamp shade,air conditioner,

cosmetics cover and so on.

Or it can be made as customers’ requirement.

Specifications

color aluminum coil

1000 series 1100 10160 1200

surface could be: Brushed, drawing, embossed, printing

color: red,

color aluminum coil

.Alloy type: 1050/1060/1100/1350

2.Temper: H16, H18, H22, H24

3.Thickness range: 0.1mm-4mm

4.Width range: 25mm-1600mm

5.Surface:finish: bright & smooth surface, without flow lines, slight oiled to avoid white rusting.

6.Quality material:totally free from such defefects as roll marks, edge damager, camber, white rust, oil patches, holes, break lines,

color aluminum coil

Name |

color aluminum coil |

Alloy or not | yes |

Alloy | 1100H16/18, 3003H24,3003H26,3005H26,8011,3004,3105,5005,etc. |

Thickness | 0.1-4mm |

Width | ≤1600mm |

MOQ | 5T |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

- Q:Can aluminum coils be used for outdoor applications?

- Yes, aluminum coils can be used for outdoor applications. Aluminum is highly resistant to corrosion and weathering, making it a suitable choice for outdoor use. Additionally, aluminum coils are lightweight, durable, and have excellent thermal conductivity, making them ideal for various outdoor applications such as roofing, gutters, and HVAC systems.

- Q:Why there is arc panel after aluminum coil straightening?

- The aluminum coil can only become flat and straight after being planished on stretch bender.

- Q:Can aluminum coils be customized or fabricated into specific shapes?

- Yes, aluminum coils can be customized or fabricated into specific shapes. Aluminum has excellent formability and can be easily shaped using various fabrication techniques such as rolling, bending, stamping, and extrusion. These processes allow the aluminum coils to be transformed into specific shapes, such as sheets, plates, tubes, and profiles, to meet the specific requirements of different applications. Additionally, aluminum can also be welded, joined, or cut to further customize its shape and size. This versatility in customization makes aluminum coils a preferred choice in various industries, including automotive, aerospace, construction, and manufacturing.

- Q:What is the weight of an aluminum coil?

- The weight of an aluminum coil can vary depending on its size, thickness, and length. Therefore, it is not possible to provide a specific weight without additional information.

- Q:How are aluminum coils protected against dust and dirt during storage?

- Aluminum coils are protected against dust and dirt during storage through various measures to ensure their quality and prevent any potential damage. One common method is to wrap the coils securely with a protective covering, such as plastic or polyethylene sheets, to create a barrier against dust and dirt particles. This covering is usually tightly sealed to prevent any contaminants from entering. In addition to the wrapping, other precautions are taken to minimize the risk of dust and dirt accumulation. Storage areas are often kept clean and free from debris to reduce the likelihood of contaminants settling on the coils. Regular cleaning and maintenance of the storage space are necessary to maintain a dust-free environment. Moreover, proper ventilation and air filtration systems are employed in storage facilities to control airborne particles and maintain a clean atmosphere. These systems help to reduce the amount of dust and dirt that can settle on the coils. It is also crucial to handle the aluminum coils with care during transportation and storage to avoid unnecessary exposure to dust and dirt. Employing proper handling equipment and techniques, such as using clean gloves and avoiding dragging the coils on the ground, can prevent the accumulation of contaminants. By implementing these protective measures, aluminum coils can be stored safely and securely, ensuring their quality remains intact and preventing any potential issues caused by dust and dirt accumulation.

- Q:How are aluminum coils used in the production of musical instruments?

- Aluminum coils are widely used in the production of musical instruments due to their unique properties and advantages. One of the main uses of aluminum coils is in the manufacturing of guitar pickups. These coils are wound around a magnetic core and serve as the primary component for capturing the vibrations of the guitar strings and converting them into electrical signals. The electromagnetic properties of aluminum make it an excellent material for this purpose as it allows for the precise sensing and amplification of the instrument's sound. In addition to guitar pickups, aluminum coils are also utilized in the production of other instruments such as electric keyboards, synthesizers, and electric violins. These coils are essential for the generation and transmission of sound signals, ensuring high-quality audio output. Aluminum's lightweight nature makes it a preferred choice as it doesn't add unnecessary weight to the instrument, allowing for ease of handling and improved portability. Moreover, aluminum coils are employed in the construction of wind instruments like saxophones and trumpets. They are used to shape the tubing and create the body of these instruments. Aluminum's corrosion resistance properties are particularly valuable in this application, as it helps to maintain the instrument's durability and longevity. Overall, aluminum coils play a vital role in the production of musical instruments by providing a reliable means of capturing, transmitting, and amplifying sound signals. Their unique properties, such as electromagnetic sensitivity and corrosion resistance, make them an ideal choice for ensuring high-performance and longevity in various musical instruments.

- Q:How are aluminum coils used in the production of window frames?

- Aluminum coils are used in the production of window frames as they are shaped and formed into the desired profile using specialized machinery. These coils are first cut to the appropriate length and then fed through a series of rollers that shape them into the required dimensions for the window frame. The coils are then joined together and fastened to create the frame structure. The use of aluminum coils provides strength, durability, and corrosion resistance to the window frames, making them ideal for both residential and commercial applications.

- Q:Are aluminum coils resistant to mold and mildew?

- Yes, aluminum coils are generally resistant to mold and mildew. Aluminum is a non-porous material, which means it does not absorb moisture like other materials such as wood or fabric. This makes it less susceptible to mold and mildew growth. Additionally, aluminum coils are often coated with protective finishes that further enhance their resistance to mold and mildew. However, it is important to note that while aluminum coils are less prone to mold and mildew, they are not completely immune. If the coils are exposed to excessive moisture or humidity, mold and mildew can still develop. Regular cleaning and maintenance are therefore necessary to prevent any potential mold or mildew growth.

- Q:What is the difference between hot-rolled and cold-rolled aluminum coils?

- The main difference between hot-rolled and cold-rolled aluminum coils lies in the production process. Hot-rolled aluminum coils are produced at high temperatures, which makes them more malleable and ductile. This process also results in a scaly surface finish. In contrast, cold-rolled aluminum coils are processed at lower temperatures, making them harder and more rigid. Cold-rolled coils have a smoother and more polished surface finish. Ultimately, the choice between hot-rolled and cold-rolled aluminum coils depends on the specific application and desired properties.

- Q:What is an aluminum coil and what is it used for?

- An aluminum coil, shaped like a rolled-up sheet of aluminum, is made from high-quality aluminum alloys known for their durability, lightweight nature, and resistance to corrosion. Aluminum coils are widely used in various industries, particularly in the manufacturing sector where they are utilized to create aluminum products like cans, containers, and packaging materials. The flexibility and malleability of aluminum coils allow them to be easily shaped into different sizes and forms. Moreover, the construction industry extensively relies on aluminum coils for multiple purposes. These coils are commonly employed in roofing, siding, gutters, and other exterior applications due to their ability to withstand harsh weather conditions and resist corrosion. Their lightweight nature also simplifies handling and installation, reducing labor and transportation expenses. Furthermore, aluminum coils play a crucial role in heating, ventilation, and air conditioning (HVAC) systems. They are integral components in the production of condenser and evaporator coils, which are essential for regulating temperature and humidity in residential, commercial, and industrial buildings. To summarize, aluminum coils are highly versatile and valuable materials that have widespread applications in numerous industries. Their lightweight nature, resistance to corrosion, and malleability make them an excellent choice for manufacturing aluminum products, as well as for construction and HVAC applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1060 Temper H18 0.5mm 0.6mm 0.7mm Thick Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords