All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is seamless steel pipe protected against external corrosion?

Seamless steel pipes are protected against external corrosion through a variety of methods. One common approach is to apply a protective coating or layer on the surface of the pipe. This coating acts as a barrier, preventing direct contact of the steel with external corrosive elements such as moisture or chemicals. Additionally, the pipes can be galvanized, which involves applying a layer of zinc to the surface. Zinc acts as a sacrificial anode, meaning it corrodes before the steel, thereby protecting the pipes. Other methods include using corrosion inhibitors or cathodic protection, where a sacrificial metal is connected to the steel pipe to attract corrosion and protect the pipe.

What are the different heat treatment processes for seamless steel pipe?

Some of the different heat treatment processes for seamless steel pipes include annealing, normalizing, quenching, and tempering. Annealing involves heating the steel pipe to a specific temperature and then slowly cooling it, which helps to improve its ductility and reduce internal stresses. Normalizing is a similar process, but the cooling rate is faster, resulting in a finer grain structure and improved mechanical properties. Quenching involves rapidly cooling the steel pipe in a liquid medium, such as oil or water, to achieve high hardness and strength. Tempering is often performed after quenching to reduce the brittleness of the steel and improve its toughness and ductility. These heat treatment processes can be tailored to meet specific requirements of the steel pipe's application.

Can seamless steel pipes be used for railway tracks?

No, seamless steel pipes cannot be used for railway tracks. Railway tracks require specialized rails made of steel that are specifically designed to withstand the heavy loads and constant wear and tear associated with train traffic. Seamless steel pipes are more commonly used in industries such as oil and gas, construction, and plumbing.

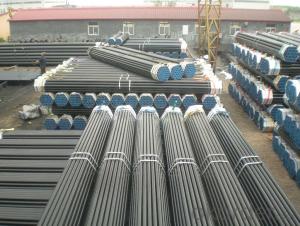

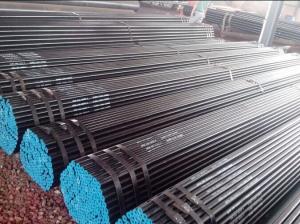

Wholesale Seamless Steel Pipe from supplier in Latvia

Whether you require Seamless Steel Pipe products for construction, industrial, or infrastructure projects in Latvia, our team is dedicated to delivering high-quality solutions. We understand the importance of efficiency and reliability in these sectors, and our products are designed to meet the highest industry standards.

With our comprehensive sales and quoting services, we ensure competitive pricing and accurate product information. Our technical support team is always available to assist you with any queries or requirements you may have, ensuring a smooth and hassle-free procurement process.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to offer a wide range of Seamless Steel Pipe products, including various sizes, grades, and specifications to meet your specific project needs.

Our years of market development in Latvia have given us valuable insights into the local industry and regulations. We understand the unique challenges and requirements of the Latvian market, and our team is well-equipped to provide you with the necessary expertise and guidance.

At our company, we are committed to customer satisfaction and strive to exceed your expectations. We pride ourselves on delivering top-quality products, excellent customer service, and timely delivery. Trust us to be your reliable partner for all your Seamless Steel Pipe procurement needs in Latvia.

With our comprehensive sales and quoting services, we ensure competitive pricing and accurate product information. Our technical support team is always available to assist you with any queries or requirements you may have, ensuring a smooth and hassle-free procurement process.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to offer a wide range of Seamless Steel Pipe products, including various sizes, grades, and specifications to meet your specific project needs.

Our years of market development in Latvia have given us valuable insights into the local industry and regulations. We understand the unique challenges and requirements of the Latvian market, and our team is well-equipped to provide you with the necessary expertise and guidance.

At our company, we are committed to customer satisfaction and strive to exceed your expectations. We pride ourselves on delivering top-quality products, excellent customer service, and timely delivery. Trust us to be your reliable partner for all your Seamless Steel Pipe procurement needs in Latvia.